Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding Head Pulley Mechanics and Applications in Modern Engineering

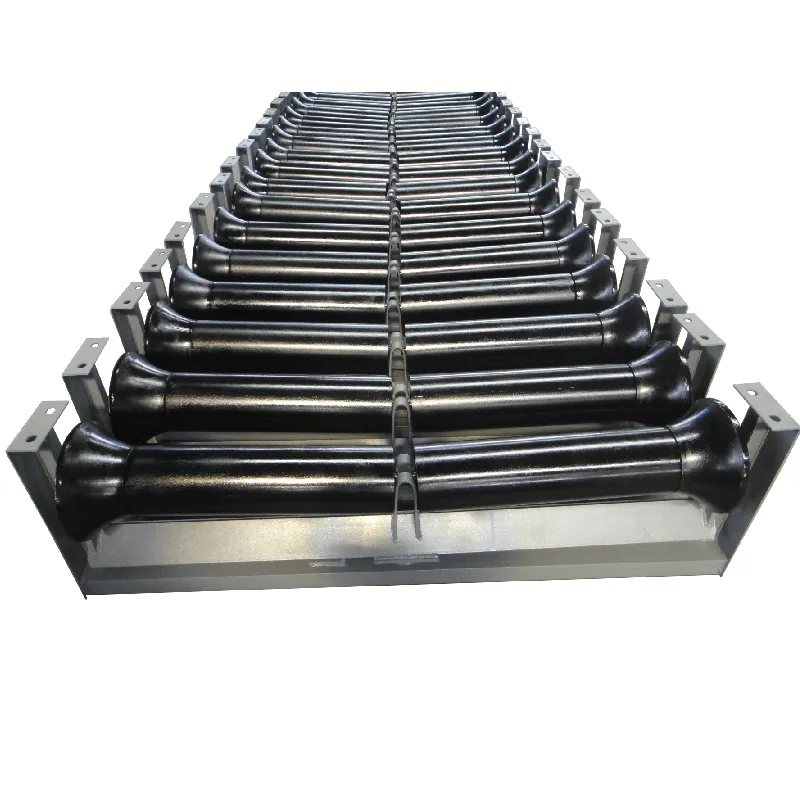

The Importance of Head Pulleys in Conveyor Systems

In various industrial settings, the efficiency of material handling systems plays a crucial role in operational productivity. One critical component that significantly contributes to the overall functionality of these systems is the head pulley. This article will explore the essential functions of head pulleys, their design characteristics, and their implications for efficiency and safety in conveyor systems.

Understanding Head Pulleys

A head pulley is positioned at the discharge end of a conveyor system, acting as a crucial mechanism for the movement and direction of conveyed materials. Typically mounted on a horizontal or inclined plane, the head pulley works in tandem with the conveyor belt, ensuring the seamless transportation of materials from one location to another.

Head pulleys can be classified into two main categories drive pulleys and non-drive pulleys. Drive pulleys are powered, providing the necessary force to move the conveyor belt, while non-drive pulleys serve primarily to redirect the belt and support its weight.

Design Characteristics

The design of a head pulley is vital to the efficiency and longevity of the conveyor system. Key considerations in the design process include the diameter, material, and surface finish of the pulley.

1. Diameter Generally, the diameter of a head pulley affects its ability to drive the belt effectively. A larger diameter pulley can improve the belt's performance by reducing wear and tear over time, thereby enhancing the system's overall reliability.

2. Material Head pulleys are typically made from materials that offer a good blend of strength, durability, and resistance to wear. Common materials include steel and rubber, which can withstand the harsh conditions often present in industrial environments. The choice of material also impacts the head pulley’s traction and grip on the conveyor belt.

3. Surface Finish The surface finish of a head pulley is critical to its ability to grip the conveyor belt effectively. Smooth finishes can lead to slippage, while textured or rubberized surfaces enhance friction, minimizing the risk of material loss during transport.

head pulley

Functional Role in Conveying Systems

The head pulley serves multiple functions within a conveyor system

1. Material Discharge The primary function of the head pulley is to facilitate the discharge of materials at the end of the conveyor. As the belt moves, bulk materials are conveyed and then released as they pass over the head pulley.

2. Belt Tensioning Proper tensioning of the belt is essential for maintaining its functionality. The head pulley helps maintain the tension by creating a uniform distribution of forces along the conveyor system, preventing slippage and ensuring optimal performance.

3. Change of Direction Head pulleys assist in changing the direction of the conveyor belt, which is essential for complex conveyor layouts. This helps in efficiently routing materials throughout a facility.

Implications for Efficiency and Safety

The efficiency of head pulleys directly impacts the overall operations of conveyor systems. An optimally functioning head pulley enables smooth material flow, reducing downtime and bottlenecks. This efficiency translates into cost savings for businesses, enhancing their productivity and profit margins.

Moreover, safety is a paramount concern in industrial operations. Well-designed head pulleys contribute to the safety of conveyor systems by reducing the risk of accidents related to belt slippage or material spillage. Moreover, using pulleys with the appropriate diameter and material ensures that the system operates within its designed parameters, further enhancing workplace safety.

Conclusion

In conclusion, head pulleys are critical components of conveyor systems that play a significant role in material handling efficiency and safety. Their design characteristics, functional roles, and implications for operational performance highlight their importance in various industrial applications. As industries continue to evolve, the focus on improving head pulley design and functionality will remain paramount in enhancing the overall efficiency and safety of conveyor systems. Understanding these components can provide valuable insights into optimizing material handling processes, ensuring that industries operate smoothly and effectively.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025