Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu head pulley

The Role of Head Pulley in Modern Machinery

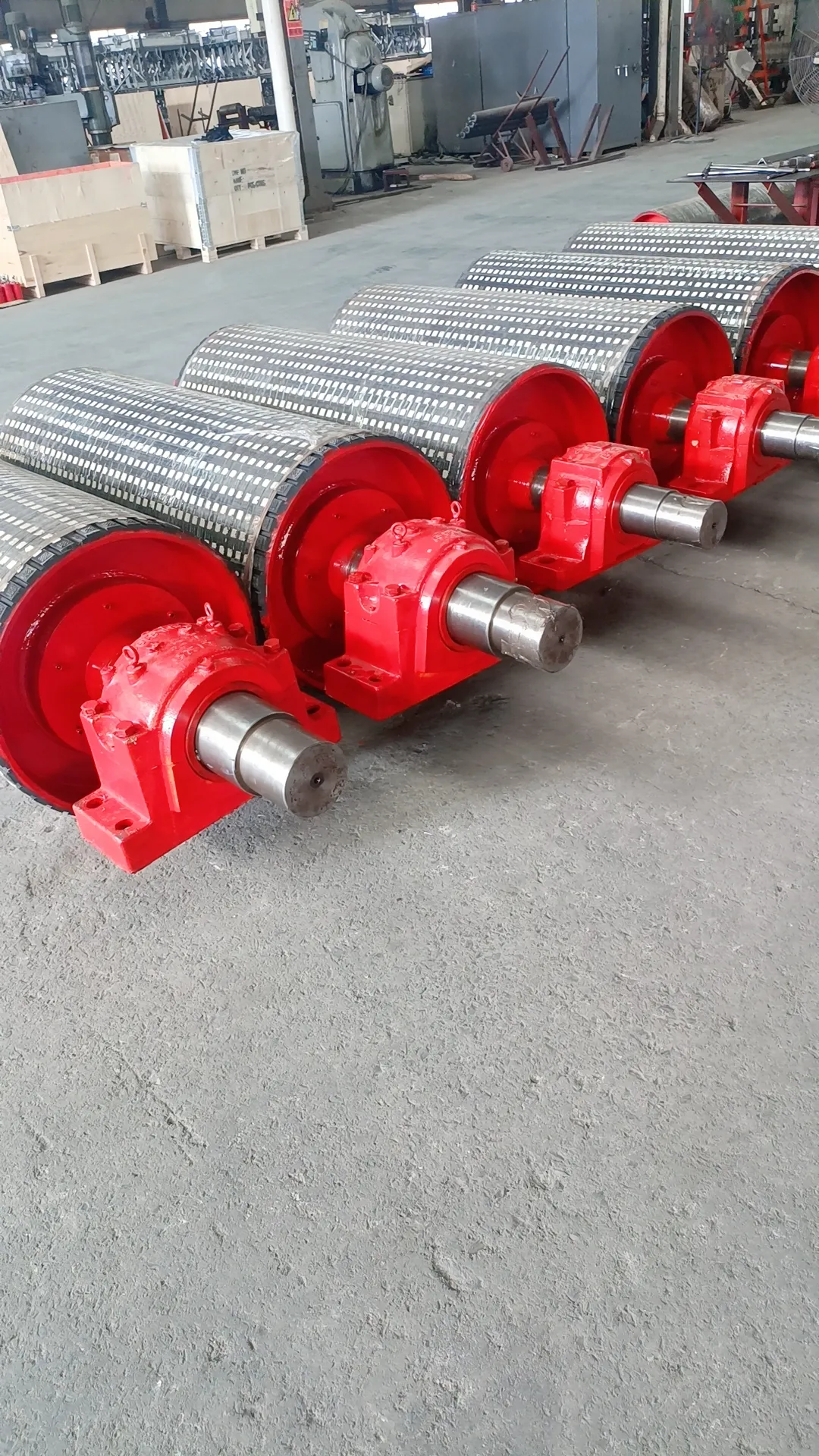

In the realm of mechanical engineering and design, the head pulley serves as a crucial component in the functioning of various conveyor systems. These systems are integral to numerous industries, including mining, manufacturing, and material handling. The head pulley operates as the driving force that enables the movement of materials along a conveyor belt, thereby streamlining processes and enhancing operational efficiency.

A head pulley is typically positioned at the discharge end of a conveyor system and plays a dual role. Firstly, it is responsible for driving the conveyor belt, ensuring that it runs smoothly and consistently. The rotation of the head pulley creates motion that propels the belt forward, allowing it to transport materials from one location to another. Secondly, the head pulley is crucial for the tensioning of the belt. Proper tension is essential to prevent slippage and to maintain the integrity of the system, ensuring that materials are transported reliably.

Head pulleys come in various designs and configurations, depending on the application requirements. They can be equipped with features such as lagging, which provides additional traction and improves the grip between the belt and the pulley. Lagging is often made from rubber or ceramic materials that enhance the friction between the pulley and the belt, thereby preventing slippage, especially in heavy-duty applications where the weight of transported materials can be significant.

One of the primary advantages of utilizing a head pulley in conveyor systems is the efficiency it introduces. By providing a reliable means of transporting materials, head pulleys reduce manual labor and minimize the risk of human error. This allows industries to optimize their operations, increase productivity, and ultimately reduce costs. Furthermore, the continuous movement of materials facilitates faster processing times, which is particularly vital in fast-paced industries.

head pulley

Moreover, modern head pulleys are designed with durability and maintenance in mind. High-quality materials and engineering practices ensure that these components can withstand harsh operating conditions, including exposure to abrasive materials, extreme temperatures, and significant mechanical stress. Regular maintenance, such as lubrication and inspection, is essential to prolonging the lifespan of the head pulley and ensuring smooth operation.

In addition to the conventional uses, head pulleys can also be integrated with advanced technology for enhanced performance. For instance, they can be equipped with sensors that monitor the operational parameters, such as tension and temperature, allowing for real-time data collection and analysis. This capability is instrumental in predictive maintenance, where potential issues can be identified and addressed before they lead to system failures. By leveraging technology, industries can further improve their efficiency and reduce downtime.

Environmental considerations are also becoming increasingly important in the design and operation of conveyor systems. Manufacturers are now exploring eco-friendly materials and processes to produce head pulleys, aiming to reduce the overall carbon footprint of their operations. Energy-efficient designs are being implemented to minimize power consumption, aligning with the broader industry push towards sustainability.

In conclusion, the head pulley is an indispensable element of modern conveyor systems, playing a vital role in the movement and management of materials across various industries. Its ability to drive, tension, and secure the conveyor belt ensures that operations run smoothly and efficiently. With continuous advancements in technology and a growing emphasis on sustainability, the future of head pulleys looks promising, paving the way for more innovative applications in the industrial landscape. As industries evolve, so will the components that drive them, making the head pulley a keystone in the machinery of tomorrow.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025