Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Mechanics of Gravity-Driven Pulley Systems in Everyday Applications

The Mechanics and Applications of Gravity Take-Up Pulleys

In the realm of mechanical engineering and material handling systems, the concept of gravity take-up pulleys plays a crucial role in maintaining the tension of conveyor belts. These ingenious devices are essential for ensuring the smooth and efficient operation of various industries, ranging from mining and quarrying to manufacturing and agriculture. In this article, we will explore the working principle, design, and applications of gravity take-up pulleys, as well as their importance in promoting operational efficiency and longevity of conveyor systems.

Understanding the Basics

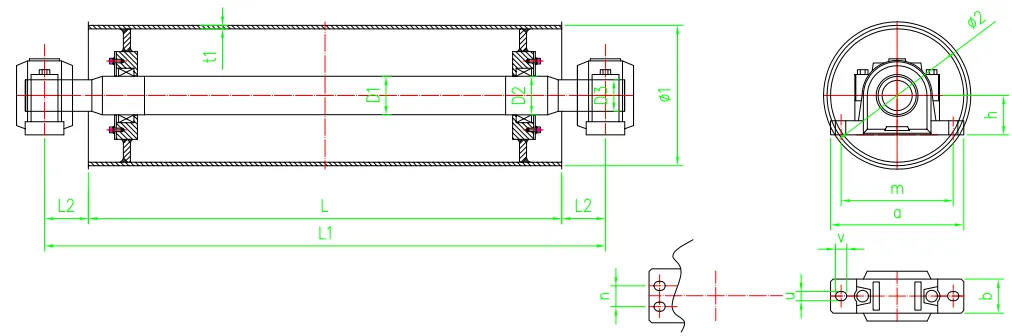

At its core, a gravity take-up pulley is designed to counteract the slack that can develop in a conveyor belt due to wear, thermal expansion, and load variations. When a conveyor belt is in motion, it experiences tension changes that can lead to slippage or derailment if not properly managed. A gravity take-up system employs a pulley and a weight mechanism to automatically adjust the belt tension, ensuring consistent operation.

The design typically consists of a pulley mounted at the end of the conveyor system, with a counterweight suspended from it. As the belt expands or contracts, the pulley moves in response, either adding or relieving tension. This self-regulating capability is vital in minimizing wear and tear on the belt and associated equipment.

The Mechanics and Applications of Gravity Take-Up Pulleys

One of the primary advantages of a gravity take-up pulley is its ability to enhance the efficiency and reliability of conveyor systems. By maintaining proper tension, these devices reduce the risk of belt misalignment, which can lead to significant downtime and maintenance costs. Additionally, they help to extend the lifespan of the conveyor belt itself—proper tension is critical for preventing ripping or tearing, which can occur if the belt is either too loose or too tight.

gravity take up pulley

Moreover, gravity take-up systems are relatively simple in terms of design and operation. They do not require complex electronic controls or frequent adjustments, making them a cost-effective solution for many industries. Their low-maintenance nature appeals to operators who prioritize efficiency and reliability over manual intervention.

Applications Across Industries

Gravity take-up pulleys find applications in a diverse array of industries. In mining operations, for instance, they are crucial for transporting materials from extraction sites to processing facilities. The rugged environments and high loads often encountered in this sector necessitate reliable tension management solutions. Similarly, in the agricultural sector, gravity take-up systems are used in grain handling facilities to facilitate the movement of crops without damaging the delicate products.

In manufacturing, conveyor belts are an integral part of assembly lines, and maintaining the correct tension is vital for ensuring that products move seamlessly through the various stages of production. Heavy-duty gravity take-up pulleys are also utilized in recycling operations, where they aid in managing the flow of materials while minimizing belt failures.

Conclusion

Gravity take-up pulleys represent a vital component of modern conveyor systems, enabling the transport of goods and materials efficiently and safely. Their ability to maintain consistent tension not only prolongs the life of conveyor belts but also optimizes overall operational efficiency. As industries continue to innovate and demand higher performance from their equipment, the role of gravity take-up pulleys will undoubtedly increase, serving as a reliable solution for tension management. In this way, these devices not only address immediate mechanical challenges but also contribute to the sustainable development of industrial operations.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025