Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 17, 2025 23:24

Back to list

return idler bracket

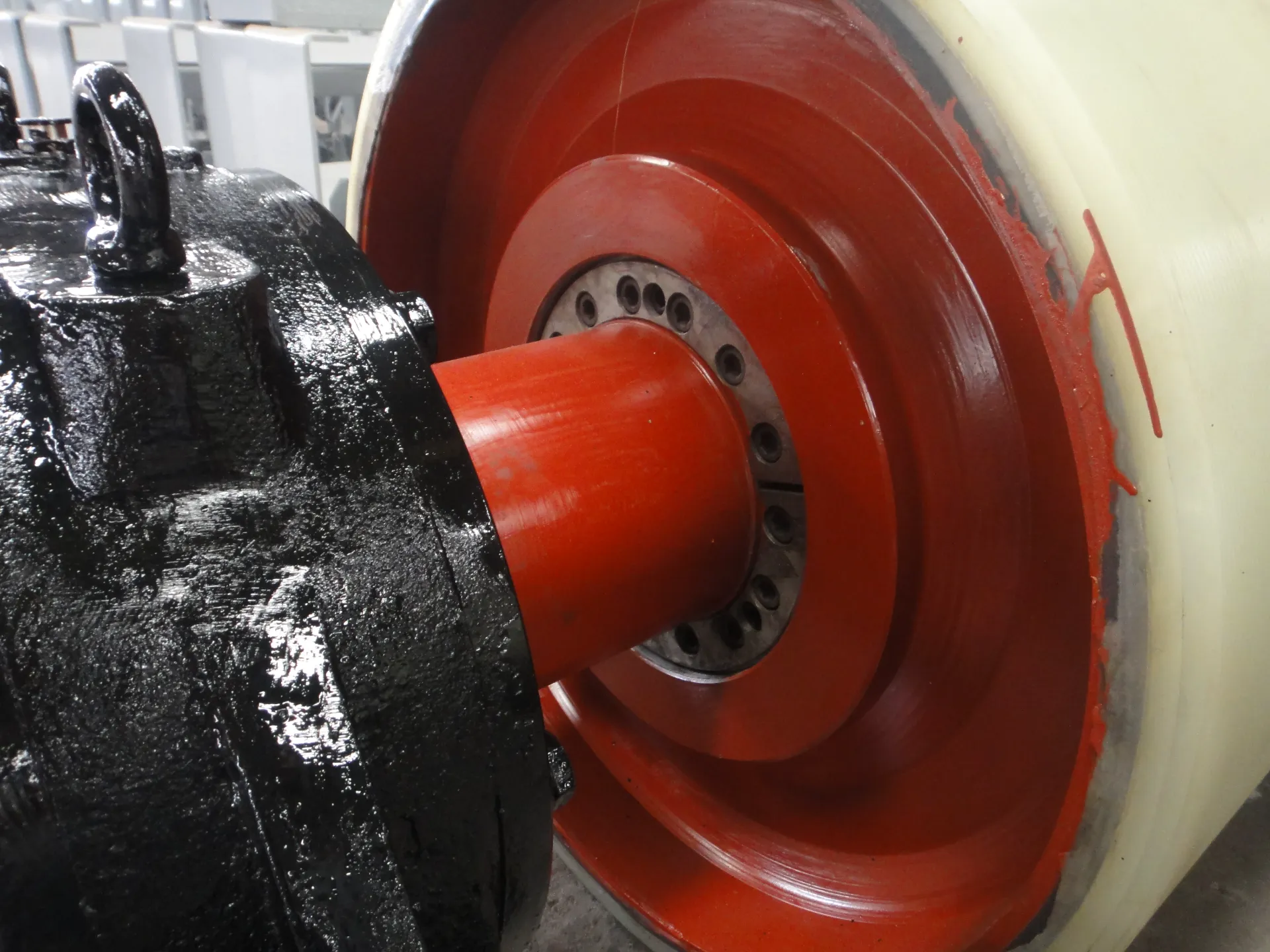

Flat return idlers are pivotal components in the conveyor belt systems, ensuring smooth and efficient operation across various industries. These indispensable parts are not merely about functionality; they are a testament to engineering precision and reliability.

Authoritativeness in the field of conveyor components often stems from rigorous testing and adherence to industry standards. Flat return idlers manufactured under strict quality control processes earn credibility through certifications and endorsements from industry standard bodies. These certifications ensure that products meet specific performance criteria and safety regulations, thereby providing peace of mind to the end users. Companies producing these idlers often engage in continuous research and development to adapt to evolving industry needs, setting benchmarks in quality and innovation. Trustworthiness is engendered through consistent performance and reliability. Users of flat return idlers often testify to the reduced operational hiccups and maintenance interventions, attributing this to the idlers' robust design and construction. Trust is further built through warranties that accompany these products, providing assurance of the manufacturer's confidence in their offerings. Customer support and service play a crucial role here, as professional guidance and timely assistance foster a trustworthy relationship between manufacturers and users. For businesses planning to invest in or upgrade their conveyor systems, understanding the operational benefits and technological nuances of flat return idlers is crucial. By making informed decisions based on real-world performance data and industry expertise, businesses can optimize their operations. The right choice of flat return idlers can enhance productivity, reduce operational costs, and extend the life expectancy of conveyor systems. In conclusion, the flat return idler, while a humble component, is integral to the optimal functioning of conveyor systems. Its role in ensuring belt stability, reducing wear, and prolonging equipment life makes it indispensable in high-stakes industries. The blend of experience, expertise, and trustworthiness associated with these idlers underscores their importance in modern industrial applications. As industries evolve, so too will the technology behind flat return idlers, promising further innovations that will continue to drive efficiency and reliability in material handling systems.

Authoritativeness in the field of conveyor components often stems from rigorous testing and adherence to industry standards. Flat return idlers manufactured under strict quality control processes earn credibility through certifications and endorsements from industry standard bodies. These certifications ensure that products meet specific performance criteria and safety regulations, thereby providing peace of mind to the end users. Companies producing these idlers often engage in continuous research and development to adapt to evolving industry needs, setting benchmarks in quality and innovation. Trustworthiness is engendered through consistent performance and reliability. Users of flat return idlers often testify to the reduced operational hiccups and maintenance interventions, attributing this to the idlers' robust design and construction. Trust is further built through warranties that accompany these products, providing assurance of the manufacturer's confidence in their offerings. Customer support and service play a crucial role here, as professional guidance and timely assistance foster a trustworthy relationship between manufacturers and users. For businesses planning to invest in or upgrade their conveyor systems, understanding the operational benefits and technological nuances of flat return idlers is crucial. By making informed decisions based on real-world performance data and industry expertise, businesses can optimize their operations. The right choice of flat return idlers can enhance productivity, reduce operational costs, and extend the life expectancy of conveyor systems. In conclusion, the flat return idler, while a humble component, is integral to the optimal functioning of conveyor systems. Its role in ensuring belt stability, reducing wear, and prolonging equipment life makes it indispensable in high-stakes industries. The blend of experience, expertise, and trustworthiness associated with these idlers underscores their importance in modern industrial applications. As industries evolve, so too will the technology behind flat return idlers, promising further innovations that will continue to drive efficiency and reliability in material handling systems.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS