Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Mechanics and Applications of Conical Roller Bearings in Modern Engineering

The Role and Importance of Conical Rollers in Engineering

Conical rollers are a vital component in various engineering applications, playing a crucial role in enhancing the performance and efficiency of machinery. Their unique shape and design allow them to handle loads more effectively than traditional cylindrical rollers, making them a preferred choice in numerous industrial settings.

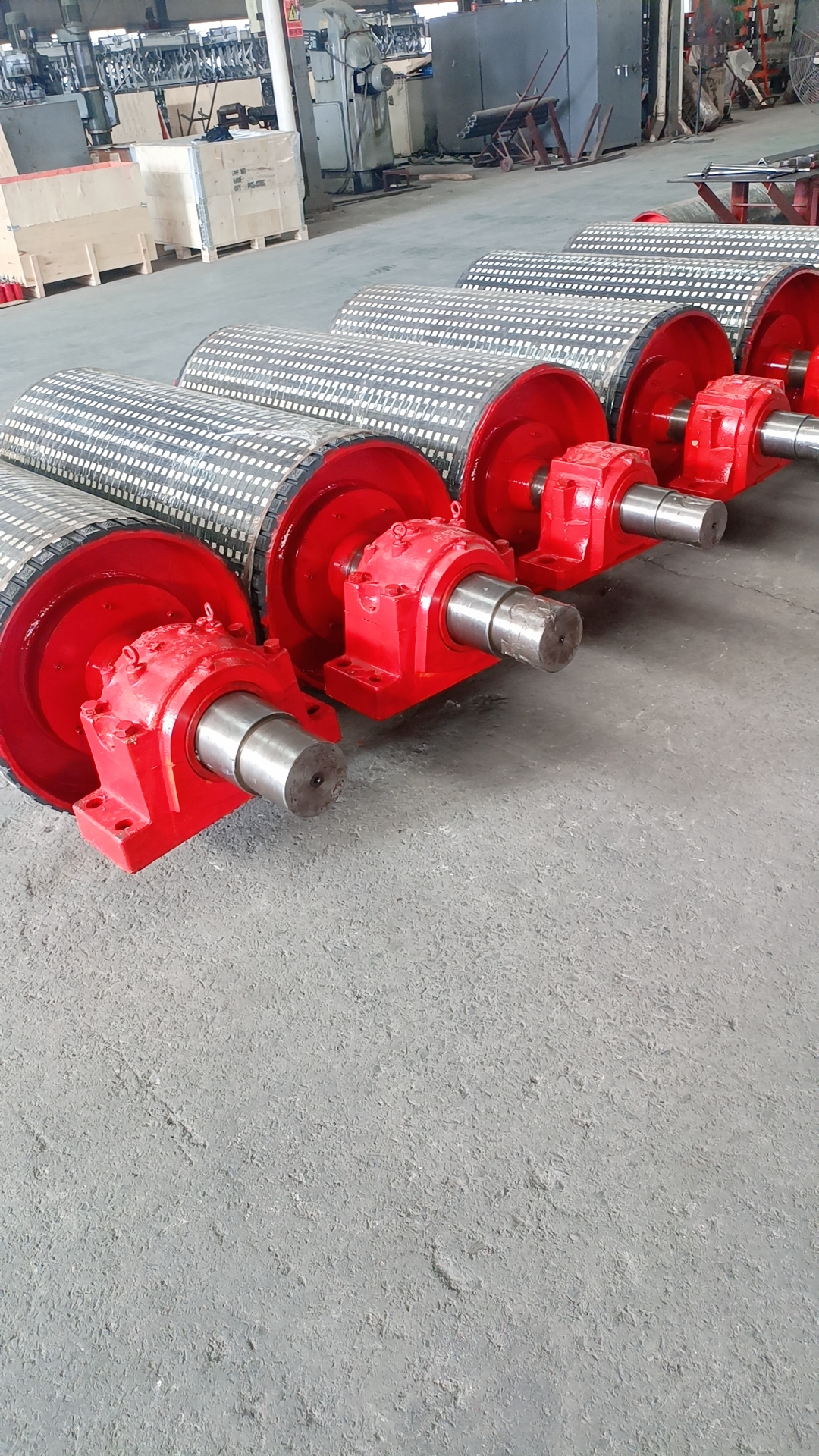

At the heart of any mechanical system, bearings are essential for reducing friction between moving parts. Conical rollers are particularly effective in applications where angular misalignment may occur. Their tapered shape allows for improved distribution of stress across the surface, thereby extending the lifespan of machinery components. This characteristic makes conical rollers ideal for use in automotive wheel bearings, gearboxes, and conveyor systems, where the alignment of parts can frequently change due to load variations or operational conditions.

One of the standout advantages of conical rollers is their ability to support both radial and axial loads. Unlike standard roller bearings, which primarily handle radial loads, conical rollers provide a dual-functionality that enhances their utility in engineering applications. This capability is particularly valuable in situations where space is limited, and the design must accommodate multiple load types without compromising performance. For example, in the automotive industry, conical roller bearings are used in differential assemblies, allowing for smooth operation as the vehicle navigates turns and varying terrains.

Manufacturing conical rollers involves precise engineering and material selection

. Typically crafted from high-strength steel or composite materials, these rollers are designed to withstand significant stresses while minimizing wear and tear. Advances in manufacturing technologies, such as heat treatment processes and surface hardening, further enhance the durability and performance of conical rollers. As production techniques continue to evolve, the application of ceramic and synthetic materials is also gaining traction, offering even greater resistance to extreme environments and corrosive substances.conical roller

In addition to their mechanical benefits, conical rollers contribute to the overall efficiency of systems. By reducing friction, they decrease energy consumption, leading to more sustainable operations. In an era where industries are increasingly focused on reducing their carbon footprint and improving energy efficiency, the role of conical rollers becomes even more significant. Their ability to optimize performance while minimizing energy loss aligns with the broader goals of modern engineering practices aimed at sustainability.

In terms of maintenance, conical roller bearings are relatively easy to inspect and service. Regular maintenance practices, such as lubrication and alignment checks, ensure that they continue to function at peak performance. Unlike some other bearing types, which may require more complex disassembly for service, conical rollers can often be adjusted or replaced without significant downtime, thereby enhancing productivity in manufacturing settings.

The application of conical rollers extends beyond traditional machinery. They are increasingly found in automation systems, robotics, and aerospace technology. In robotics, for instance, they are essential for articulating joints and support mechanisms that require precise movement and stability. In aerospace, the reliability and weight-saving characteristics of conical rollers are essential for achieving high performance in flight operations.

In conclusion, conical rollers play a pivotal role in the engineering landscape. Their ability to handle both radial and axial loads, coupled with advancements in manufacturing technologies, make them invaluable in various applications. As industries evolve and seek greater efficiency and sustainability, the importance of conical rollers will undoubtedly continue to grow, cementing their status as a cornerstone in modern engineering design.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025