Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Benefits of Using Polyurethane Coatings with Rollers for Surface Finishing

The Importance of Polyurethane in Roller Applications

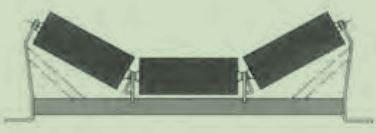

Polyurethane is a versatile and durable material that has become increasingly popular across various industries, particularly in the production of rollers. Rollers made from polyurethane are used in a wide array of applications, ranging from manufacturing to logistics, and even in specialized machinery. The choice of polyurethane offers several advantages over traditional materials like rubber or metal, making it a preferred option for many industrial applications.

Understanding Polyurethane

Polyurethane is a polymer composed of organic units connected by carbamate (urethane) links. This material can be engineered to possess a variety of properties by adjusting its chemical composition, resulting in flexible, rigid, or elastomeric forms. The ability of manufacturers to customize the hardness, elasticity, and resilience of polyurethane makes it an attractive choice for creating rollers that can withstand various operational demands.

Advantages of Polyurethane Rollers

1. Durability Polyurethane exhibits excellent wear resistance, which is crucial for rollers that are subjected to constant friction and pressure. Unlike rubber that can degrade or deform with time, polyurethane maintains its shape and function over extended periods, reducing the need for frequent replacements.

2. Load-bearing Capacity Polyurethane rollers can bear heavy loads without compromising performance. This feature is particularly important in industrial settings where heavy machinery and equipment are utilized. The high load-bearing capacity ensures that the rollers will operate effectively under challenging conditions, enhancing the overall efficiency of the system.

3. Customization One of the standout features of polyurethane is its adaptability. Manufacturers can create rollers in varying hardness levels, colors, and surface textures suited for specific applications. This customization extends to incorporating additives that enhance the roller's properties, such as UV resistance, anti-static features, or even antimicrobial functions.

polyurethane with a roller

4. Noise Reduction Polyurethane rollers generate less noise compared to their metal or rubber counterparts. This characteristic is essential in environments where minimizing noise pollution is a priority, such as in food processing plants or packaging facilities.

5. Chemical Resistance Many industrial environments expose rollers to various chemicals, including oils, solvents, and detergents. Polyurethane is inherently resistant to many of these substances, providing longevity and reliability in settings where exposure to harmful chemicals is inevitable.

6. Reduced Weight Rollers made from polyurethane are typically lighter than those made from metal. This reduction in weight can lead to easier handling and installation, as well as reduced wear and tear on machinery due to less overall load.

Applications of Polyurethane Rollers

The applications of polyurethane rollers span numerous sectors. In the manufacturing industry, they are commonly used in conveyor systems, ensuring the smooth transport of goods. In printing and packaging, these rollers are critical for achieving high-quality results. Additionally, the automotive industry uses polyurethane in various components, including rollers for assembly lines, where flexibility and durability are paramount.

Conclusion

Polyurethane has emerged as a material of choice for roller applications due to its unique properties that address the challenges faced in industrial environments. Its durability, load-bearing capacity, and customization options make it an ideal solution for a variety of applications. As industries continue to seek ways to improve efficiency and reduce costs, the demand for polyurethane rollers is likely to increase, solidifying their role in the ongoing evolution of manufacturing and logistics. By adopting polyurethane, companies can not only enhance their operational performance but also contribute to a more sustainable approach by reducing waste associated with frequent replacements and maintenance.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025