Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Benefits and Applications of Vertical Roller Technology in Modern Industries

The Advancements and Applications of Vertical Roller Mills

Vertical roller mills (VRMs) have become increasingly significant in various industries, particularly in the field of material processing. These innovative machines offer a range of advantages over traditional milling equipment, making them a preferred choice for operations requiring high efficiency and precision. This article delves into the mechanics of vertical roller mills, their operational benefits, and their diverse applications.

Understanding Vertical Roller Mills

Vertical roller mills are characterized by a vertical design where the grinding table rotates while the grinding rollers crush the material. These machines are primarily used for grinding coal, cement, and various other materials. The design allows for a highly efficient grinding process, whereby the material is crushed between the rollers and the table, providing a larger surface area for material interaction and achieving more fine particles quickly.

One of the key components of a VRM is the hydraulic system that applies pressure to the grinding rollers. This pressure ensures that the material is adequately crushed and allows for adjustable settings to cater to different material characteristics and desired particle sizes. The integration of several functions, such as drying, grinding, and separating, in a single unit is another significant feature that enhances the VRM's efficiency.

Advantages of Vertical Roller Mills

One of the most notable advantages of VRMs is their energy efficiency. Compared to traditional ball mills, VRMs consume significantly less energy while achieving the same or even higher throughput levels. This reduction in energy consumption results in lower operational costs, making VRMs an economical option for businesses.

Another critical benefit is their ability to handle a variety of materials and fineness levels. VRMs can accommodate materials with different moisture content levels, making them versatile for different production processes. Additionally, the compact design of these mills requires less space and allows for easier integration into existing production lines.

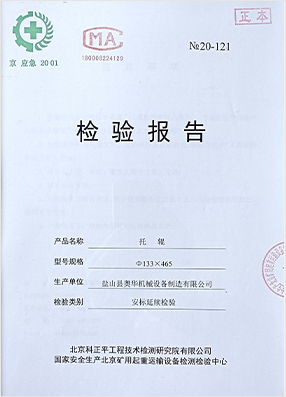

vertical roller

Moreover, vertical roller mills produce less noise and dust compared to other grinding systems, contributing to a more environmentally friendly operation. The reduced dust emissions also enhance the workplace's safety conditions for operators, making VRMs a more attractive choice in industries aiming for sustainability.

Applications of Vertical Roller Mills

Vertical roller mills have found extensive applications across various sectors. The cement industry is one of the most prominent users, where VRMs are utilized for the production of both raw meal and cement. Their ability to finely grind and blend raw materials efficiently is key to producing high-quality cement with minimal energy expenditure.

In the coal industry, VRMs play a critical role in pulverizing coal for power generation. The precise control over the grinding process ensures that the coal is adequately processed for combustion, leading to enhanced efficiency in power plants.

Beyond cement and coal, vertical roller mills are increasingly used in industries such as minerals and metals processing, where they facilitate the production of fine powders required for various products. The pharmaceutical industry also employs VRMs for the milling of active ingredients, ensuring uniformity and quality in drug manufacturing.

Conclusion

The development and implementation of vertical roller mills have revolutionized the grinding process in numerous industries. Their efficiency, versatility, and cost-effectiveness underscore their importance in modern manufacturing operations. As industries continue to seek ways to optimize processes and reduce environmental impact, vertical roller mills are likely to play an even more prominent role in the future of material processing. With ongoing technological advancements, the capabilities of VRMs are expected to expand, further solidifying their position in the market.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025