Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Enhancing Conveyor Efficiency with Polyurethane Pulley Solutions

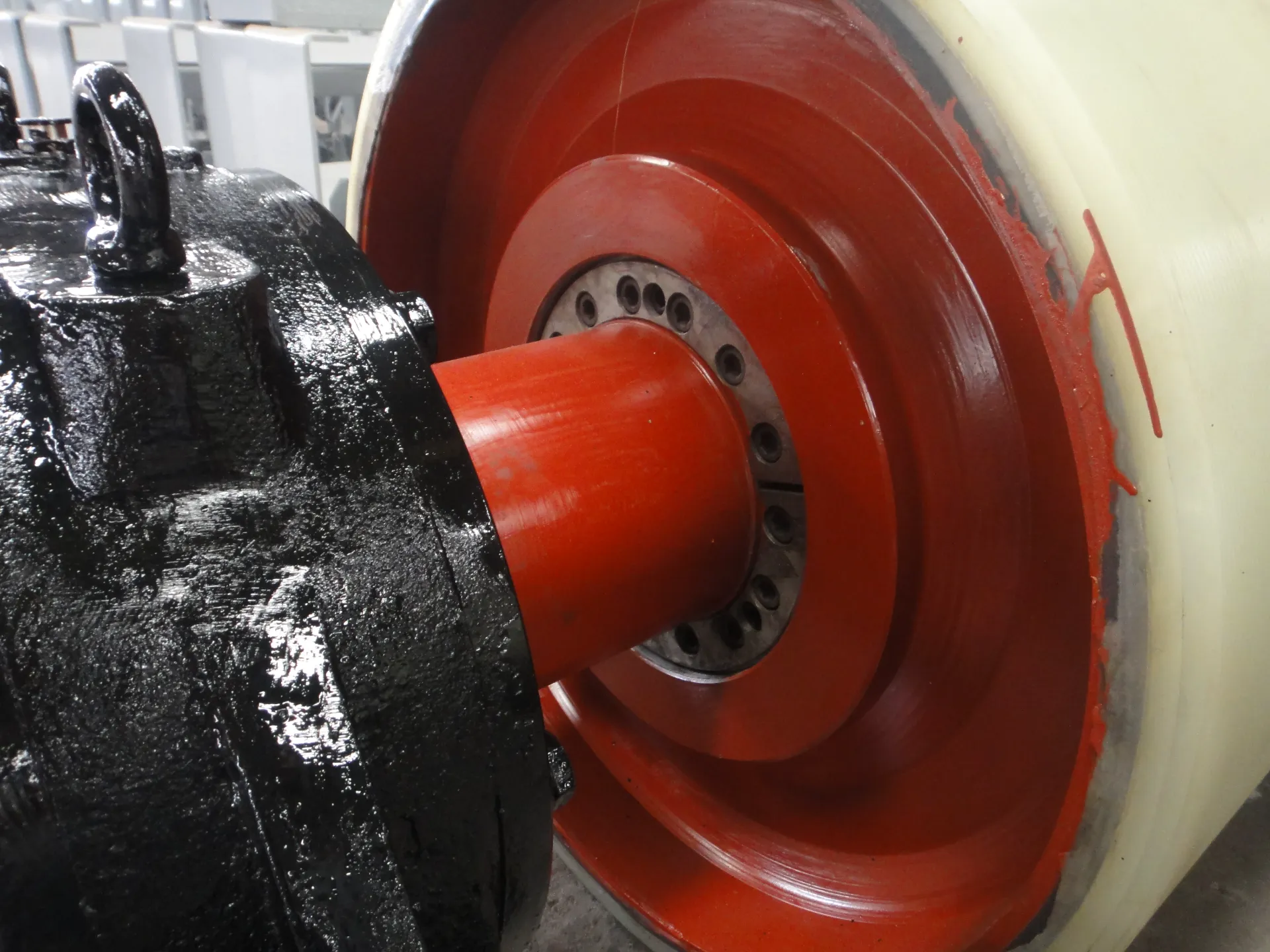

In modern industrial operations, optimizing conveyor systems is essential for maintaining high levels of efficiency and reducing downtime. One key component that contributes to system longevity and smooth functioning is the polyurethane pulley. Known for its durability, flexibility, and wear resistance, the polyurethane pulley has become an increasingly popular choice in various industries. When used in conjunction with polyurethane lagging, these pulleys can significantly improve the performance of conveyor belts.

The Durability and Versatility of Urethane Pulley

Urethane pulley are engineered to withstand harsh conditions, making them an ideal choice for conveyor systems that handle heavy loads, abrasive materials, or extreme environments. Unlike traditional metal or rubber pulleys, urethane pulley offer superior resistance to wear, corrosion, and impact. This results in reduced maintenance requirements and extended service life.

Urethane's inherent elasticity allows it to absorb shock and prevent excessive wear on the conveyor belt, ensuring a smoother operation. These pulleys are particularly effective in applications that involve frequent belt tension adjustments or where load impact is common. Additionally, urethane pulley offer excellent resistance to chemicals and UV exposure, making them suitable for both indoor and outdoor environments.

The Advantages of Polyurethane Lagging

Polyurethane lagging is a key feature that can be added to pulleys to further improve the efficiency of the conveyor system. This specialized coating is applied to the pulley’s surface to enhance grip, reduce slippage, and provide better traction between the belt and pulley. The improved traction helps to prevent belt misalignment and improves overall system performance.

Polyurethane lagging also offers superior resistance to abrasion and weathering, which ensures that the pulley remains in optimal condition even in challenging working environments. It is particularly beneficial in applications where high friction is required, such as in mining, aggregate processing, and other heavy-duty industries. By reducing the potential for slippage and increasing the longevity of both the pulley and conveyor belt, polyurethane lagging helps keep operations running smoothly.

Upgrade Your Conveyor System Today

If you're looking to improve the performance and durability of your conveyor system, consider investing in polyurethane pulley and polyurethane lagging. These advanced components can enhance operational efficiency, reduce maintenance costs, and extend the lifespan of your equipment. Upgrade your system today and experience the difference that high-quality urethane products can make in your industrial operations.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025