Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Durable Return Idler Bracket - Conveyor Roller Parts

Driving Efficiency: The Critical Role of the Return Idler Bracket in Modern Conveyor Systems

In the vast landscape of bulk material handling, conveyor systems stand as indispensable arteries, facilitating the movement of diverse materials across industries. At the heart of their seamless operation lies a network of robust components, with the return idler bracket playing a pivotal, yet often understated, role. These brackets are essential for supporting the return strand of the conveyor belt, ensuring proper alignment, preventing material spillage, and significantly extending the lifespan of the entire system. As industries push for greater efficiency, reduced downtime, and lower operational costs, the design, material, and manufacturing precision of these critical components become paramount. The global conveyor belt market, valued at approximately USD 6.5 billion in 2022, is projected to grow at a CAGR of over 4% from 2023 to 2030, underscoring the escalating demand for reliable conveyor accessories, including advanced return idler brackets, rollers and brackets, and conveyor hangers.

The contemporary industrial landscape demands not just functionality but also sustainability and longevity from its infrastructure. This trend directly influences the evolution of conveyor roller parts and related components. Manufacturers are increasingly focusing on developing return idler bracket solutions that offer enhanced durability, superior corrosion resistance, and reduced friction to minimize energy consumption. Innovations in material science and manufacturing processes are enabling the creation of lighter, yet stronger, brackets capable of withstanding extreme operational conditions, from corrosive petrochemical environments to abrasive mining sites. These advancements are crucial for sectors where continuous operation is non-negotiable, emphasizing the strategic importance of investing in high-quality conveyor accessories to maintain competitive advantage.

Precision Engineering: Manufacturing the Return Idler Bracket

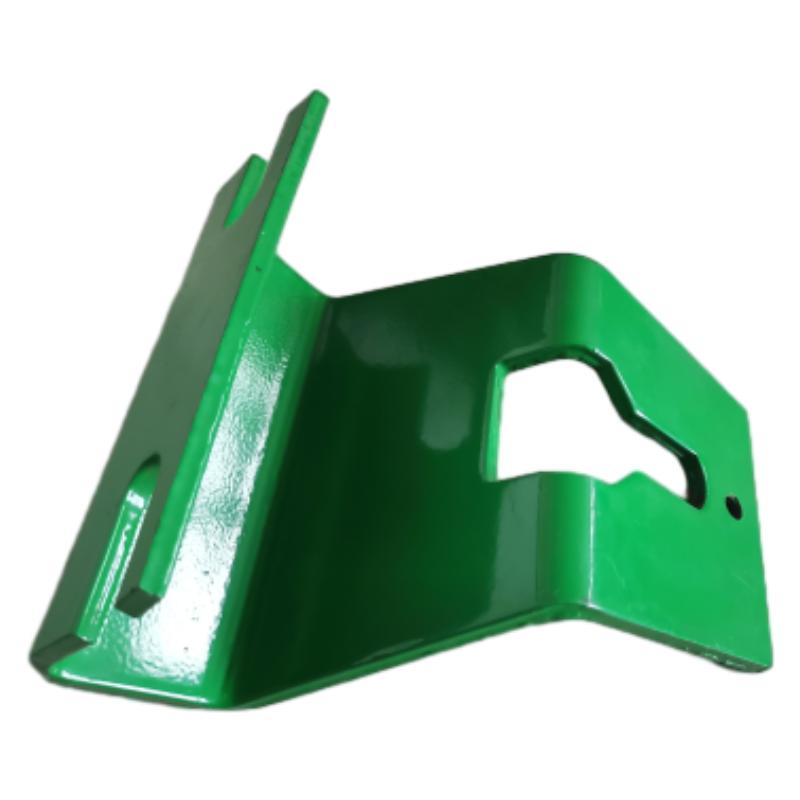

The manufacturing of a high-performance return idler bracket is a testament to precision engineering, involving a meticulous multi-stage process designed to ensure structural integrity and operational longevity. The journey begins with the selection of premium materials, typically high-grade carbon steel, stainless steel, or specialized alloys, chosen for their tensile strength, fatigue resistance, and specific environmental compatibility—such as corrosion resistance for humid or chemical-laden environments. Common manufacturing processes include advanced stamping, laser cutting, and robotic welding for structural components, followed by precision CNC machining for critical interfaces and mounting points. This ensures tight tolerances and optimal fitment with conveyor rollers and brackets, reducing vibration and wear.

Quality control is embedded at every stage. Components undergo rigorous inspections, adhering to international standards such as ISO 9001 for quality management and ANSI B105.1 for conveyor idler standards. Material testing, including metallurgical analysis, hardness testing, and non-destructive testing (NDT) like ultrasonic or magnetic particle inspection, validates material integrity. Post-fabrication, load-bearing tests, deflection tests, and comprehensive dimensional checks using Coordinate Measuring Machines (CMM) ensure each return idler bracket meets exact specifications. Surface treatments, such as hot-dip galvanization for enhanced corrosion protection or powder coating for improved abrasion resistance, are applied, extending the lifespan significantly. A well-manufactured bracket can boast an operational lifespan exceeding 5-7 years in demanding conditions, offering superior performance in industries like petrochemicals, metallurgy, power generation, and water treatment, contributing to energy savings by minimizing friction and ensuring smooth belt travel.

Figure 1: Illustration of a key stage in the manufacturing process of a robust return idler bracket.

Technical Specifications and Performance Metrics of Return Idler Brackets

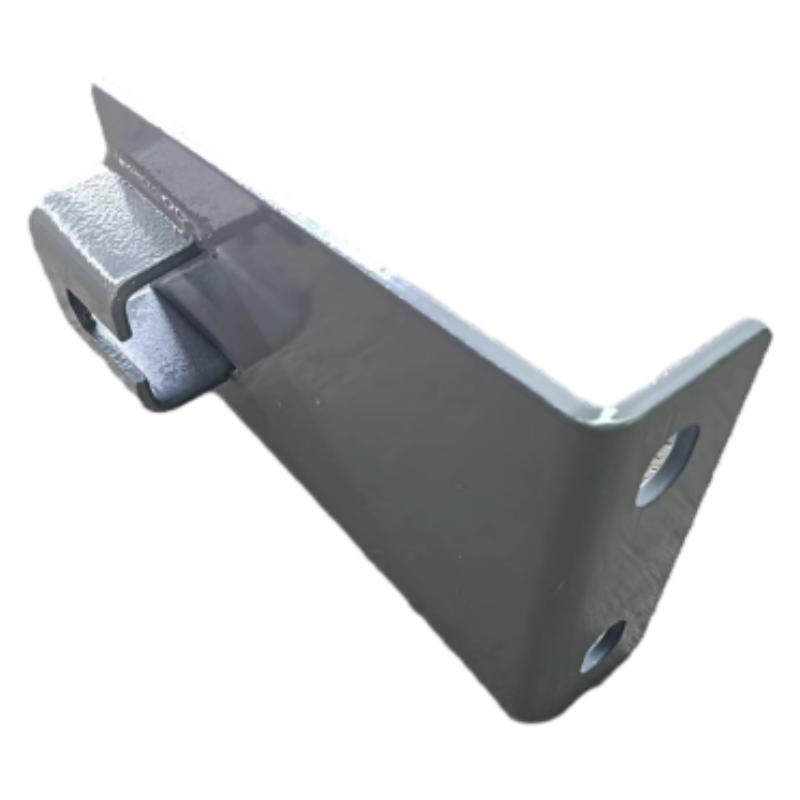

Understanding the technical specifications of a return idler bracket is crucial for engineers and procurement specialists to ensure optimal system performance and longevity. These parameters dictate the bracket's suitability for specific applications, influencing load capacity, operational stability, and resistance to environmental factors. Key specifications typically include material composition, such as Q235B carbon steel or 304 stainless steel, which determines strength and corrosion resistance. The bracket's dimensions, including width, height, and bolt hole patterns, must conform to existing conveyor structures and roller types, such as CEMA B, C, D, E, or F standards, ensuring seamless integration and ease of replacement. Bearing compatibility is also vital, as the bracket must securely house and support the idler roller bearings, preventing misalignment and premature wear.

Performance metrics extend beyond mere dimensions. Load-bearing capacity, typically measured in kilonewtons (kN), indicates the maximum weight the bracket can reliably support, critical for heavy-duty applications. Operating temperature range, from sub-zero conditions to extreme heat, dictates material selection and surface treatments. Friction coefficients are important for energy efficiency, with lower values contributing to reduced power consumption. The table below provides a typical overview of common parameters for industrial return idler brackets:

Application Scenarios and Strategic Advantages

The versatility of the return idler bracket makes it an indispensable component across a multitude of heavy industrial applications, ranging from mining and quarrying to port operations, power generation, cement production, and bulk chemical handling. In mining environments, where conveyors transport abrasive ores over long distances, high-durability brackets are crucial to resist wear from sharp materials and heavy loads, significantly reducing the frequency of maintenance and associated downtime. For port facilities, operating often in saline, corrosive atmospheres, stainless steel or heavily galvanized brackets are preferred, ensuring that material flow is uninterrupted by rust or structural degradation. In power plants and cement factories, where high temperatures and fine dust are common, specialized designs with sealed bearings and robust construction prevent contamination and ensure continuous operation.

The strategic advantages offered by superior return idler brackets are multifaceted. Firstly, their precision manufacturing guarantees optimal belt alignment, which dramatically extends the life of the conveyor belt itself—a significant operational cost. Secondly, reduced friction from well-engineered idler assemblies translates directly into lower energy consumption, offering substantial operational savings over the system's lifespan. Thirdly, their robust construction and material selection contribute to enhanced system reliability, minimizing unexpected breakdowns and maintenance interventions. This directly impacts overall productivity by maximizing uptime. Finally, the use of quality conveyor hanger systems and components like the return idler bracket is critical in complying with stringent safety regulations, preventing belt failures that could lead to accidents or material spillage. These components are integral to a comprehensive strategy for efficient bulk material handling.

Figure 2: A robust return idler bracket integrated within an operational conveyor system in a heavy industrial setting.

Choosing the Right Partner: Manufacturer Comparison and Custom Solutions

Selecting a manufacturer for return idler brackets and other conveyor roller parts is a strategic decision that profoundly impacts operational efficiency and long-term cost of ownership. Key factors to consider include the manufacturer's experience, which often translates to a deeper understanding of industry-specific challenges and robust design solutions. Certifications such as ISO 9001, along with adherence to international standards like CEMA, DIN, and JIS, signify a commitment to consistent quality and performance. A reputable manufacturer should also demonstrate strong R&D capabilities, allowing for continuous innovation in material science and design to meet evolving industrial demands. This includes offering a comprehensive range of conveyor accessories and conveyor hanger systems that are compatible and optimized for seamless integration. The ability to provide detailed technical data, including load testing reports and fatigue analysis, further underscores their expertise and commitment to quality.

For specialized applications, the availability of customized solutions is a critical differentiator. Many industrial operations face unique challenges, such as extremely corrosive environments, exceptionally high or low temperatures, or unusual load requirements. A leading manufacturer will possess the engineering expertise to design and produce custom return idler brackets tailored to these specific needs. This might involve using specialized alloys, implementing unique coating technologies, or developing bespoke mounting configurations to integrate seamlessly into existing conveyor infrastructure. The benefit of custom solutions extends beyond mere fit; they often lead to superior performance, extended operational life, and significantly reduced maintenance costs compared to off-the-shelf components. Partnering with a manufacturer capable of delivering such bespoke engineering ensures that your conveyor system is optimized for maximum efficiency and resilience, showcasing a holistic approach to providing rollers and brackets.

Real-World Impact: Application Case Study

Consider a large-scale iron ore mining operation in Western Australia that faced persistent issues with premature wear and frequent replacement of their conveyor belt components, particularly the return idler brackets, due to the highly abrasive and corrosive environment. The existing brackets, made from standard carbon steel, showed significant corrosion and structural fatigue within 18-24 months, leading to extensive downtime and high maintenance costs. Annual expenditure on replacement parts and labor for a single 10 km conveyor line exceeded $500,000. Recognizing the need for a more durable solution, the mine engaged a specialized manufacturer known for their robust conveyor accessories and custom-engineered solutions. After a thorough analysis of the site's environmental conditions and material properties, the manufacturer proposed a custom return idler bracket fabricated from marine-grade stainless steel with an advanced, multi-layer ceramic coating for superior abrasion and corrosion resistance.

The implementation of these new, custom-engineered brackets yielded significant improvements. Within the first two years, the mining company observed a remarkable 70% reduction in unscheduled downtime related to idler bracket failures. The ceramic coating effectively resisted the abrasive iron ore, and the marine-grade stainless steel showed no signs of corrosion, even in the humid, saline coastal environment. This extended lifespan of the brackets, now projected to exceed 7 years, translated into an annual saving of over $350,000 per conveyor line in maintenance and replacement costs. Furthermore, the improved stability provided by the high-precision brackets reduced belt misalignment, leading to an estimated 5% improvement in overall energy efficiency for the conveyor system. This case exemplifies how strategic investment in high-quality conveyor roller parts, particularly durable return idler brackets, can deliver substantial operational benefits and a rapid return on investment in demanding industrial settings.

Figure 3: Close-up of a high-performance return idler bracket, showcasing its robust design and material quality.

Trust and Reliability: Quality Assurance and Customer Support

In the B2B sector, trust is built upon a foundation of consistent quality, reliable performance, and unwavering support. A reputable manufacturer of return idler brackets and other conveyor accessories distinguishes itself through stringent quality assurance protocols, often backed by decades of service and partnerships with industry leaders. Our commitment to excellence is demonstrated by comprehensive testing procedures, including destructive and non-destructive testing, full-scale load simulations, and real-world fatigue testing, ensuring every product meets or exceeds international standards. We are proud to hold ISO 9001 certification, reflecting our dedication to world-class manufacturing processes and continuous improvement. Our products are engineered for maximum durability, reducing the need for frequent replacements and minimizing environmental impact, reinforcing our position as a leader in providing high-quality rollers and brackets for diverse industrial applications.

Beyond product quality, robust customer support and transparent policies are vital. We understand the critical nature of conveyor systems to your operations, which is why we offer comprehensive technical support, from initial consultation and design assistance to installation guidance and post-sales service. Our standard delivery cycle typically ranges from 4-6 weeks for custom orders, with expedited options available for urgent requirements, ensuring minimal disruption to your project timelines. Each return idler bracket and associated conveyor part is backed by a robust warranty, typically 2 years against manufacturing defects, underscoring our confidence in our products' longevity and performance. Furthermore, our dedicated FAQ section and responsive technical team are always available to address queries regarding product selection, maintenance best practices, and troubleshooting, providing unparalleled support throughout the product lifecycle.

Conclusion

The return idler bracket, while a seemingly small component, is fundamental to the efficiency, reliability, and safety of any bulk material handling conveyor system. Its design, material, and manufacturing precision directly impact operational costs, energy consumption, and overall system longevity. By investing in high-quality, expertly engineered brackets, industries can significantly reduce maintenance requirements, minimize downtime, and achieve substantial long-term savings. The ongoing innovation in conveyor accessories, driven by demands for greater durability and performance, underscores the evolving importance of every component in the conveyor chain. Partnering with a manufacturer committed to precision engineering, robust quality assurance, and comprehensive customer support ensures that your conveyor systems operate at their peak performance, safeguarding your investments and enhancing productivity for years to come.

References

- Conveyor Equipment Manufacturers Association (CEMA) Standard No. 502-2004. Specifications for Conveyor Idlers.

- British Standards Institution (BSI). BS EN 15367-1:2010. Conveyor belts - Parameters for idler design.

- American National Standards Institute (ANSI). ANSI/ASME B20.1-2018. Safety Standard for Conveyors and Related Equipment.

- International Organization for Standardization (ISO). ISO 9001:2015. Quality management systems – Requirements.

- Journal of Engineering Research. "Optimization of Conveyor Idler Design for Enhanced Energy Efficiency in Bulk Material Handling."

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025