Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

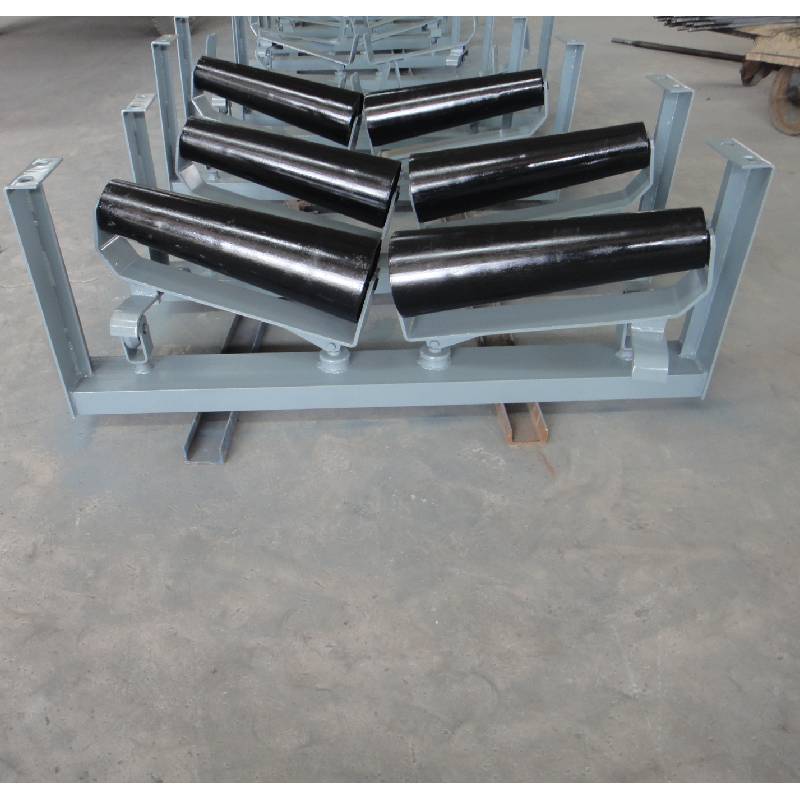

Zulu Durable Idler Rollers for Belt Conveyors | Steel & Rubber Types

Navigating Industrial Excellence: Top Mechanical Manufacturers at China International Industry Fair (CIIF)

Introduction: The Gateway to Industrial Innovation at CIIF

The China International Industry Fair (CIIF) stands as a pivotal global stage, drawing together the brightest minds and most innovative technologies in the industrial sector. For B2B decision-makers seeking advanced solutions, CIIF is an unparalleled opportunity to witness cutting-edge developments in mechanical engineering and manufacturing. This year, the focus intensifies on companies that are not just participating, but leading, particularly in specialized areas like high-precision components for material handling systems. As a key exhibitor, Yanshan Aohua Machinery Equipment Manufacture Limited Company showcases innovative and high-precision components, aiming to expand international distribution networks and secure new projects for critical industrial infrastructure.

The value CIIF brings to the entire mechanical industry cannot be overstated. It's a nexus for innovation, collaboration, and market expansion, especially for components fundamental to the efficiency of industrial processes, such as idler rollers for belt conveyors. These seemingly small, yet critically engineered, components are the unsung heroes of heavy industry, ensuring smooth, reliable, and efficient material transport in mining, ports, power plants, and countless other sectors. Understanding the manufacturers driving excellence in this space is crucial for any business looking to optimize its operational backbone and achieve peak performance.

Industry Trend Spotlight: The Evolution of Industrial Components and Material Handling

The global mechanical industry, particularly within material handling and industrial components, is undergoing a profound transformation. There's an increasing demand for automated and integrated production lines, pushing manufacturers to innovate beyond traditional designs. Smart controls, such as PLC/CNC integration, are becoming standard for enhanced precision and efficiency, even in components like advanced idler rollers with bearings. Modular designs are gaining traction, allowing for flexible customization and easier maintenance, while remote diagnostics and IoT-enabled predictive maintenance are revolutionizing how equipment performance is monitored and managed. This paradigm shift also extends to the development of machinery capable of processing new advanced materials, leading to components that offer both weight reduction and superior strength.

Market data underscores this growth trajectory: The global industrial machinery and components market, specifically for material handling equipment, is projected for steady growth. This expansion is primarily driven by increasing demand from the automotive (especially EV components requiring efficient production lines), construction, and general manufacturing sectors. Key trends include an unwavering push for automation to combat rising labor costs, a relentless demand for higher precision and efficiency in every component – including specialized steel idler rollers and rubber idler rollers – and significant growth in emerging markets. While challenges such as raw material price volatility, supply chain disruptions, and intense competition persist, the industry's resilience and adaptability are paving the way for sustained innovation.

Emerging focus areas are shaping the future of industrial components:

- Industry 4.0 integration in material processing, leading to smarter, connected idler roller assembly systems.

- Advanced automation for production lines, enhancing the role of precise idlers and rollers in continuous operations.

- Energy-efficient manufacturing solutions, reducing operational costs and environmental impact, even for heavy-duty idler roller types.

- Smart predictive maintenance for machinery, allowing for proactive servicing of idler rollers for belt conveyors, minimizing downtime.

- Sustainable material handling in various industrial applications, emphasizing durability and longevity of components.

Profiles of Leading Manufacturers: Innovation at the Core

Yanshan Aohua Machinery Equipment Manufacture Limited Company

As a distinguished exhibitor at CIIF, Yanshan Aohua Machinery Equipment Manufacture Limited Company stands out for its deep specialization and expertise in a core range of industrial components critical for material handling: specifically, idler rollers for belt conveyors. Our commitment to engineering excellence is reflected in our comprehensive product line, which includes robust steel idler rollers, versatile rubber idler rollers, and precision training idlers designed for optimal belt alignment. We are renowned for producing high-quality idler rollers with bearings that ensure smooth operation and extended lifespan, minimizing friction and energy consumption in demanding industrial environments.

Yanshan Aohua boasts established manufacturing capabilities that allow for highly customized solutions, catering to the unique specifications of diverse industries. Our competitive pricing strategies, combined with an unwavering focus on superior engineering and comprehensive after-sales support, position us as a trusted partner for complex industrial equipment. Whether it's a standard idler roller assembly or specialized idler roller types like our advanced taper aligning idlers, we are dedicated to delivering reliability and performance.

Other Noteworthy Mechanical Industry Leaders at CIIF

While Yanshan Aohua specializes in the vital segment of idler rollers for belt conveyors, the CIIF showcases a broader spectrum of leading mechanical manufacturers, each contributing significantly to global industrial progress:

- SMS Group (Germany): A global leader in plant construction and mechanical engineering for the steel and non-ferrous metal industry, known for integrated solutions.

- Fives Group (France): An industrial engineering group with a strong presence in various sectors, including aluminum, steel, glass, and logistics, offering sophisticated process equipment.

- Danieli (Italy): Renowned for its complete range of plant and equipment for the iron and steel industry, from raw material to finished products, focusing on innovation and sustainability.

- Schuler Group (Germany): A technology and global market leader in forming technology, providing customized, cutting-edge presses and automation solutions.

- Wuxi Fuda Machinery Co., Ltd. (China): A prominent Chinese manufacturer, particularly in coil processing lines such as slitting and cut-to-length lines.

These companies, alongside specialized manufacturers like Yanshan Aohua, collectively demonstrate the dynamic and diverse landscape of the mechanical industry showcased at CIIF, offering solutions across the entire industrial value chain.

Market Outlook & Opportunities: The Road Ahead for Mechanical Components

The future of the mechanical industry, especially in critical components like idler rollers for belt conveyors, is profoundly shaped by several key upcoming trends and evolving buyer demands. Buyers are increasingly seeking not just products, but comprehensive solutions that integrate seamlessly into modern industrial ecosystems. The emphasis is shifting towards components that offer enhanced durability, higher efficiency, and smart capabilities.

Significant opportunities lie in the continuous evolution of automation. As industries strive for lights-out manufacturing and reduced human intervention, the reliability of every component, including every idler roller and idler roller assembly, becomes paramount. Smart manufacturing is another frontier, where idler rollers with bearings might incorporate sensors for real-time monitoring of temperature, vibration, and rotation speed, feeding data into a centralized system for predictive maintenance. This allows for proactive intervention, drastically reducing unexpected downtime and maintenance costs.

Sustainability is no longer just a buzzword; it's a core demand. Manufacturers are looking for idler roller types that are more energy-efficient, made from recyclable materials, and designed for longer lifespans, minimizing their environmental footprint. This includes advanced rubber idler rollers designed for minimal friction and wear, as well as robust steel idler rollers built to withstand harsh conditions with reduced need for replacement. The integration of IoT and AI in monitoring equipment performance, including training idlers for precise belt alignment, presents a vast area for innovation and value creation.

Buyer/Business Takeaways: Strategic Investments for Industrial Growth

For B2B decision-makers, understanding these trends translates into strategic investment decisions. Investing in high-quality mechanical components, particularly durable and efficient idler rollers for belt conveyors, makes significant financial and operational sense. Superior quality idlers and rollers translate directly into:

- Reduced Downtime: Fewer breakdowns and less frequent replacements.

- Lower Maintenance Costs: Less need for repairs and part changes.

- Increased Operational Efficiency: Smoother material flow and lower energy consumption.

- Enhanced Safety: Reliable components reduce risks of operational failures.

When considering partnerships with Chinese manufacturers, a few tips can help secure successful collaborations:

- Prioritize Quality and Certifications: Look for manufacturers with international quality standards and proven track records, like Yanshan Aohua's commitment to precision engineering in its steel idler rollers and rubber idler rollers.

- Emphasize Customization: Many Chinese manufacturers, including Yanshan Aohua, excel at tailored solutions. Clearly communicate specific requirements for idler roller assembly or unique idler roller types.

- Assess After-Sales Support: Ensure there's robust technical assistance, spare parts availability, and warranty provisions, crucial for long-term equipment reliability.

- Leverage Technology: Inquire about idler rollers with bearings that incorporate smart features for IoT integration and predictive maintenance capabilities.

Adopting future-proof strategies involves embracing smart components and integrated systems. This means not just purchasing components, but investing in solutions that offer longevity, adaptability, and data-driven insights. For instance, opting for training idlers that actively monitor belt alignment can prevent costly damage, while robust idler rollers for belt conveyors designed for extreme conditions ensure operational continuity in challenging environments.

Conclusion: Shaping the Future of Industrial Efficiency

The China International Industry Fair (CIIF) continues to be a crucial platform, not only for showcasing the breadth and depth of China's mechanical manufacturing capabilities but also for shaping the global market for industrial components and solutions. It's where the future of industrial efficiency, automation, and sustainability is forged through innovative products and strategic partnerships. For specialized components like idler rollers for belt conveyors, the fair highlights the critical role of precision engineering and advanced manufacturing in driving industrial progress worldwide.

As industries worldwide strive for greater efficiency and reliability, the contributions of companies like Yanshan Aohua Machinery Equipment Manufacture Limited Company become indispensable. Their dedication to producing high-quality idler rollers, including specialized taper aligning idlers, ensures that material handling systems operate at peak performance, enabling industries to meet growing demands with confidence.

Discover how Yanshan Aohua's advanced idler roller solutions can elevate your operations.

Explore Our Taper Aligning Idlers & More

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025