Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 09, 2025 11:41

Back to list

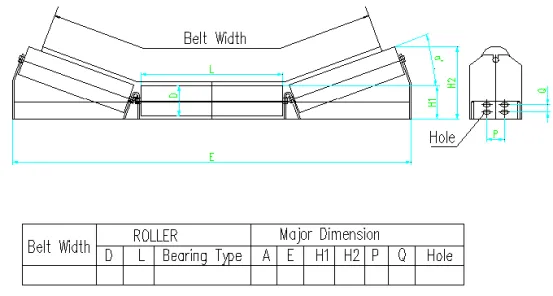

belt conveyor drum pulley manufacturers

Drum pulley manufacturers play a crucial role in the industrial machinery landscape, especially within the conveyor systems sector. Among the many components in conveyor mechanics, drum pulleys are paramount, ensuring the efficiency, longevity, and reliability of the entire assembly. Understanding the intricacies of drum pulley manufacturing can elevate your business’s operational capabilities.

Trustworthiness in drum pulley manufacturing is often built through rigorous quality assurance protocols. Many manufacturers adhere to internationally recognized standards, such as ISO certifications, ensuring products are consistently of high quality. Detailed testing regimes—including dynamic balancing, non-destructive testing, and fatigue analysis—demonstrate a commitment to product excellence and reliability, fostering long-term customer trust. Incorporating state-of-the-art manufacturing techniques also brings a competitive advantage. Companies embracing automation, precision machining, and real-time analytics in their production processes lead the industry. By reducing human error and enhancing production speed, these methodologies ensure consistent product quality and innovation. From an experiential perspective, successful drum pulley manufacturers often leverage decades of accumulated knowledge and adapt it to contemporary challenges. Insights drawn from handling a diverse array of industries—such as mining, automotive, and agriculture—equip these manufacturers to address unforeseen complications with seasoned expertise. In conclusion, the realm of drum pulley manufacturing is marked by a blend of expert material selection, innovative design, strict quality assurance, and evolving manufacturing techniques. Companies that excel are those that marry traditional manufacturing wisdom with modern technological advances. They offer not just products but solutions tailored to enhance the operational proficiency of conveyor systems across industries, establishing themselves as trusted partners in industrial advancement.

Trustworthiness in drum pulley manufacturing is often built through rigorous quality assurance protocols. Many manufacturers adhere to internationally recognized standards, such as ISO certifications, ensuring products are consistently of high quality. Detailed testing regimes—including dynamic balancing, non-destructive testing, and fatigue analysis—demonstrate a commitment to product excellence and reliability, fostering long-term customer trust. Incorporating state-of-the-art manufacturing techniques also brings a competitive advantage. Companies embracing automation, precision machining, and real-time analytics in their production processes lead the industry. By reducing human error and enhancing production speed, these methodologies ensure consistent product quality and innovation. From an experiential perspective, successful drum pulley manufacturers often leverage decades of accumulated knowledge and adapt it to contemporary challenges. Insights drawn from handling a diverse array of industries—such as mining, automotive, and agriculture—equip these manufacturers to address unforeseen complications with seasoned expertise. In conclusion, the realm of drum pulley manufacturing is marked by a blend of expert material selection, innovative design, strict quality assurance, and evolving manufacturing techniques. Companies that excel are those that marry traditional manufacturing wisdom with modern technological advances. They offer not just products but solutions tailored to enhance the operational proficiency of conveyor systems across industries, establishing themselves as trusted partners in industrial advancement.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS