Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu drum pulley manufacturers

The Role of Drum Pulley Manufacturers in Modern Industries

In the ever-evolving landscape of manufacturing and processing industries, drum pulleys play a crucial role. These mechanical devices are essential components in various systems, facilitating the efficient transfer of power and movement. Drum pully manufacturers are at the forefront of this sector, providing high-quality products that meet the diverse needs of different applications.

Understanding Drum Pulleys

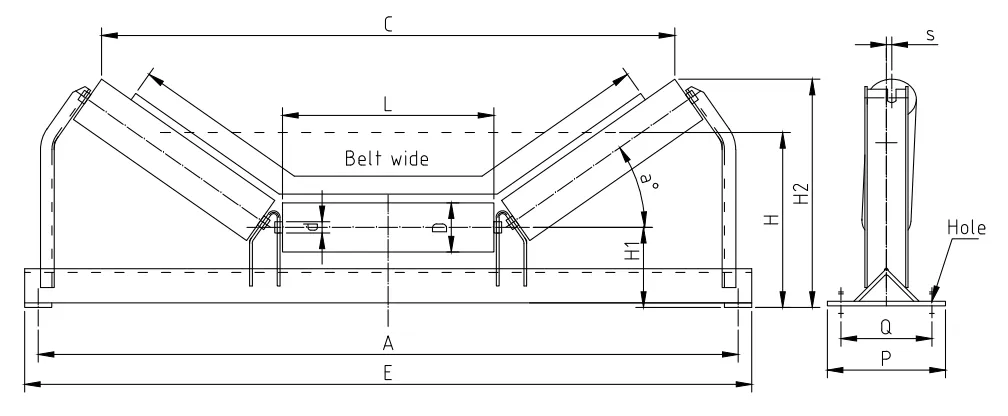

Drum pulleys, as their name suggests, are cylindrical devices used in conveyor systems to transmit motion and support belts. They can be categorized into various types, including drive pulleys, return pulleys, and snub pulleys, each serving a specific function within a conveyor system. The primary purpose of these pulleys is to guide and elevate materials while maintaining the belt's tension and alignment.

Importance of Quality Manufacturing

The quality of drum pulleys significantly impacts the efficiency and reliability of conveyor systems. Poorly manufactured pulleys can lead to belt misalignment, increased wear and tear, and ultimately, system failures. This is where the expertise of drum pulley manufacturers comes into play. These manufacturers utilize advanced materials, precision engineering, and innovative technologies to produce durable and efficient drum pulleys.

Advanced Technologies and Innovations

Today’s drum pulley manufacturers are investing heavily in research and development to stay competitive. Innovations such as state-of-the-art coating techniques, heat treatment for enhanced durability, and the use of lightweight yet strong materials have revolutionized the industry. Furthermore, advancements in computer-aided design (CAD) and simulation technologies enable manufacturers to create highly optimized pulleys tailored to specific operational requirements.

drum pulley manufacturers

Meeting Industry Standards

Compliance with industry standards is paramount for drum pulley manufacturers. Whether adhering to ISO certifications or specific industry guidelines such as those set by the Conveyor Equipment Manufacturers Association (CEMA), manufacturers must ensure that their products meet rigorous quality and safety criteria. This not only guarantees the reliability of the pulleys but also builds trust among clients.

Custom Solutions for Diverse Applications

Different industries have unique requirements for drum pulleys. For instance, mining operations may demand heavy-duty pulleys capable of handling abrasive materials, while food processing industries require pulleys that meet hygiene standards. Leading manufacturers offer custom solutions, enabling clients to choose specifications such as size, material, and coating based on their operational demands. This flexibility is critical for optimizing system performance across various applications.

Global Reach and Local Impact

The demand for drum pulleys is not restricted to a particular region. Manufacturers are expanding their reach globally, supplying their products to industries worldwide, from manufacturing plants to logistics hubs. This globalization fosters competition, encouraging manufacturers to improve their offerings continually. At the same time, local manufacturers often have the advantages of quicker turnaround times and tailored services, catering specifically to regional demands and challenges.

Conclusion

Drum pulley manufacturers play an indispensable role in the machinery that drives modern industries. Their commitment to quality, innovation, and customization allows them to meet the diverse needs of their clients while ensuring the efficiency and reliability of conveyor systems. As industries continue to evolve, these manufacturers will remain key players in enhancing productivity and operational success. In a world increasingly reliant on advanced manufacturing practices, the importance of high-quality drum pulleys cannot be overstated.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025