Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 18, 2025 06:39

Back to list

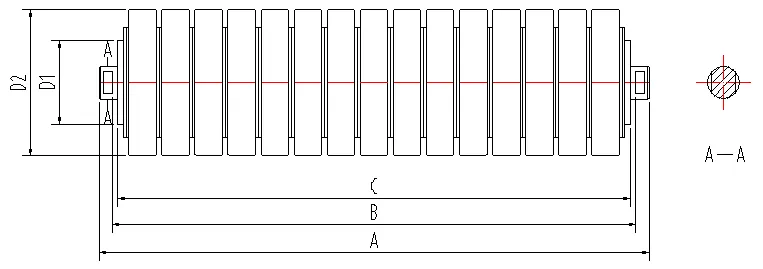

belt conveyor drum pulley manufacturers

In the realm of material handling systems, the drum pulley for conveyor belts is a cornerstone of efficient operation. These vital components play a pivotal role in maintaining the fluid movement of goods, enhancing operational efficiency, and reducing downtime in industries ranging from mining to logistics.

In logistics and warehouse settings, lightweight yet resilient pulleys made of aluminum are often utilized. These environments require high-speed operations with frequent stops and starts, so the drum pulleys must be adept at managing quick transitions without sacrifice in belt integrity. Here, the choice of a pulley can be the determining factor in maintaining operational efficiency and reducing energy consumption. For maintenance personnel and system designers, understanding the lifecycle and operational limits of drum pulleys is crucial. Regular inspections for signs of wear, such as surface cracks or alignment issues, can prevent unplanned downtime and costly repairs. Upgrading to newer models with advanced technologies can enhance the belt drive's dependability and performance. Several case studies reflect the transformative impact of well-selected drum pulleys. A notable example involves a large-scale manufacturing plant that experienced frequent conveyor belt failures due to inadequate pulleys. Upon collaborating with experts to redesign their pulley specification, productivity increased by 30%, and maintenance costs fell dramatically. This highlights the potential for drum pulleys to significantly alter the operational landscape of any industry reliant on conveyor belts. The authoritative knowledge on drum pulleys underscores their role not just as passive components but as active enhancers of industrial efficiency. By leveraging advancements in material science and engineering, businesses can ensure their conveyor systems remain at the forefront of operational excellence, benefiting from reduced downtime, enhanced safety, and improved throughput. In conclusion, drum pulleys are not mere accessories in conveyor systems but critical components that embody Experience, Expertise, Authoritativeness, and Trustworthiness. Proper understanding and application of these devices can transform material handling processes, resulting in heightened efficiency and economic gains. For industries seeking to optimize their conveyor operations, investing in high-quality drum pulleys is an indispensable strategy.

In logistics and warehouse settings, lightweight yet resilient pulleys made of aluminum are often utilized. These environments require high-speed operations with frequent stops and starts, so the drum pulleys must be adept at managing quick transitions without sacrifice in belt integrity. Here, the choice of a pulley can be the determining factor in maintaining operational efficiency and reducing energy consumption. For maintenance personnel and system designers, understanding the lifecycle and operational limits of drum pulleys is crucial. Regular inspections for signs of wear, such as surface cracks or alignment issues, can prevent unplanned downtime and costly repairs. Upgrading to newer models with advanced technologies can enhance the belt drive's dependability and performance. Several case studies reflect the transformative impact of well-selected drum pulleys. A notable example involves a large-scale manufacturing plant that experienced frequent conveyor belt failures due to inadequate pulleys. Upon collaborating with experts to redesign their pulley specification, productivity increased by 30%, and maintenance costs fell dramatically. This highlights the potential for drum pulleys to significantly alter the operational landscape of any industry reliant on conveyor belts. The authoritative knowledge on drum pulleys underscores their role not just as passive components but as active enhancers of industrial efficiency. By leveraging advancements in material science and engineering, businesses can ensure their conveyor systems remain at the forefront of operational excellence, benefiting from reduced downtime, enhanced safety, and improved throughput. In conclusion, drum pulleys are not mere accessories in conveyor systems but critical components that embody Experience, Expertise, Authoritativeness, and Trustworthiness. Proper understanding and application of these devices can transform material handling processes, resulting in heightened efficiency and economic gains. For industries seeking to optimize their conveyor operations, investing in high-quality drum pulleys is an indispensable strategy.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS