Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu drive shaft pulley

Understanding Drive Shaft Pulleys An Essential Component of Machinery

Drive shaft pulleys play a crucial role in various mechanical systems, particularly in automotive and industrial applications. They are integral components that transmit power from the engine to different parts of a machine, improving efficiency and performance. This article aims to delve into the working principles, applications, and maintenance of drive shaft pulleys, highlighting their importance in machinery.

The Working Principle of Drive Shaft Pulleys

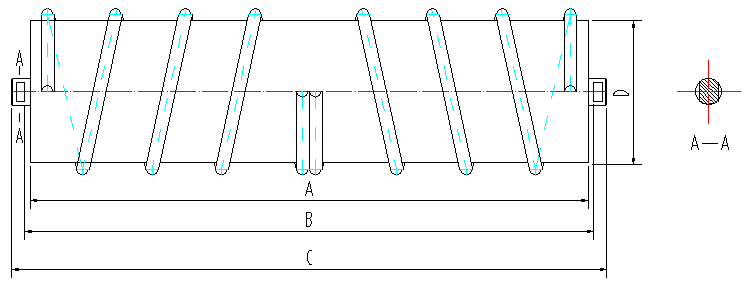

A drive shaft pulley is a wheel with a grooved rim where a belt can run. It is typically mounted on a shaft and is connected to other components via a belt or chain. As the engine runs, the drive shaft pulley rotates, causing the belt to move along its grooved surface. This motion transfers energy from the engine to other parts of the machinery, such as the alternator, water pump, or power steering system.

The efficiency of power transmission is largely dependent on the design and material of the pulley. Lightweight materials such as aluminum or high-strength plastic are often used to reduce the rotational inertia, enhancing the performance of the overall system. The pulley diameter and groove design also significantly impact torque and speed, affecting how power is distributed throughout the machine.

Applications of Drive Shaft Pulleys

Drive shaft pulleys find applications across a diverse array of industries. In the automotive sector, they are used to connect the crankshaft to various accessories, ensuring that components such as power steering pumps, air conditioning compressors, and alternators operate effectively. The automotive drive system relies heavily on these pulleys for efficient energy transfer, contributing to the overall performance and durability of vehicles.

drive shaft pulley

In industrial settings, drive shaft pulleys are commonly found in conveyor systems, fans, and compressors. They help in coordinating the movement of heavy loads and optimizing the functions of various machinery. The timing and synchrony facilitated by drive shaft pulleys are vital for processes such as assembly lines, where precision and reliability are critical.

Maintenance and Care

While drive shaft pulleys are designed for durability, regular maintenance is essential to ensure their longevity and performance. Over time, wear and tear can occur due to friction, heat, and environmental factors. It is crucial to inspect pulleys for signs of damage, such as cracks, misalignment, or excessive wear on the grooves.

Lubrication is another important aspect of maintenance. Regularly applying lubricant can reduce friction between the pulley and the belt, minimizing wear and prolonging service life. Furthermore, ensuring that the belt tension is properly adjusted can prevent slippage and decrease the likelihood of damage to the pulley system.

Conclusion

Drive shaft pulleys are vital components in both automotive and industrial applications, playing a key role in power transmission and system efficiency. Understanding their working principles, applications, and maintenance needs is essential for anyone involved in mechanical engineering, automotive repair, or industrial operations. As technology continues to evolve, advancements in pulley design and materials will further enhance their performance, paving the way for more efficient and reliable machinery. Ensuring proper care and maintenance of these components will not only optimize performance but also extend their lifespan, making them indispensable in the world of mechanics.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025