Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu drive rollers for conveyors

Drive Rollers for Conveyors An Essential Component in Material Handling

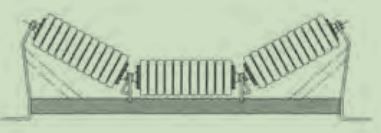

Drive rollers play a critical role in the operation of conveyor systems, serving as the driving force that moves materials efficiently along production lines and other industrial settings. These components are used in various applications, from manufacturing and warehousing to packaging and distribution. Understanding the features, functions, and types of drive rollers is essential for optimizing conveyor systems and ensuring smooth material handling processes.

Functionality and Importance

Drive rollers are designed to transmit motion and provide traction on conveyor belts. They are typically powered by electric motors, which generate rotational force that is transferred to the rollers. As the drive rollers rotate, they pull the conveyor belt along the track, creating a continuous flow of materials. This mechanism is vital for streamlining operations, reducing manual labor, and enhancing productivity.

Moreover, drive rollers help maintain the alignment and positioning of the conveyor belt. By ensuring that the belt remains taut and centered, they reduce the risk of slippage and misalignment, which can lead to operational disruptions. The efficient performance of drive rollers directly impacts the overall effectiveness and reliability of the entire conveyor system.

Types of Drive Rollers

There are several types of drive rollers, each tailored to specific applications and operational requirements. The most common types include

1. Supported Drive Rollers These are installed vertically on the conveyor frame to provide structural integrity and support. They are often used in gravity conveyors where no external power source is available.

drive rollers for conveyors

2. Powered Drive Rollers These rollers are equipped with motors and drive systems that allow for controlled movement of the conveyor belt. They are ideal for automated systems requiring precise control of speed and direction.

3. Lagging Drive Rollers Lagging refers to the material bonded to the surface of the roller to enhance gripping capabilities. This type is particularly useful in applications where products have varying weights or where slippage may occur.

4. Weighted Drive Rollers These rollers include additional weight or mass to increase the traction and grip on the belt, making them suitable for heavy loads or challenging environments.

Applications

Drive rollers are ubiquitous in various industries, including automotive, aerospace, food and beverage, pharmaceuticals, and retail. In warehousing, they facilitate the movement of pallets and packages, while in manufacturing plants, they ensure a seamless flow of components to assembly lines. In the food industry, drive rollers must meet stringent hygiene standards, necessitating the use of materials that are easy to clean and resistant to contaminants.

Conclusion

In summary, drive rollers are indispensable components of conveyor systems, ensuring that materials move efficiently and reliably throughout different stages of production and distribution. Understanding the various types of drive rollers and their specific applications can help businesses enhance their operational efficiencies and reduce downtime. As industries continue to evolve and demand for efficient material handling solutions increases, the role of drive rollers will remain vital in advancing automation and logistics processes.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025