Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu drive pulley shaft

Understanding Drive Pulley Shaft A Key Component in Mechanical Systems

In the realm of mechanical engineering, the drive pulley shaft plays a crucial role in ensuring the efficient transmission of power and motion within various machinery. From automobiles to industrial equipment, the functionality of these systems heavily relies on the performance of the drive pulley shaft. This article will delve into the significance, design, materials, and applications of drive pulley shafts.

What is a Drive Pulley Shaft?

A drive pulley shaft is a cylindrical component that serves as part of a pulley system, designed to transfer rotational motion from a power source, such as a motor, to another component, such as a wheel or gear. The pulley attached to the shaft can alter the direction of the force applied, reduce motor load, or increase torque, depending on the configuration of the mechanistic setup.

The Importance of Drive Pulley Shafts

The drive pulley shaft is integral to many mechanical systems. Their primary functions include

1. Power Transmission Drive pulley shafts are designed to withstand high torque loads during the power transmission process. They facilitate a smooth connection between the motor and other components, ensuring consistent operation. 2. Efficiency Improvement By using different pulley sizes and configurations, mechanical systems can achieve various speed ratios. This flexibility improves overall system efficiency, allowing machines to operate under optimal conditions.

3. Load Distribution A well-designed drive pulley system helps distribute load evenly across the machinery components, reducing wear and tear and extending the lifespan of the equipment.

Design Considerations

When designing a drive pulley shaft, several factors must be considered

1. Material Selection The choice of material is critical. Common materials include steel, aluminum, and composite materials. Steel is known for its high strength and durability, making it suitable for heavy-duty applications, while aluminum is lighter and more resistant to corrosion.

2. Diameter and Length The dimensions of the shaft affect its performance. A larger diameter can handle more torque, while the length needs to be optimized to fit within the mechanical assembly without causing misalignment.

drive pulley shaft

3. Surface Finish A smooth surface finish helps reduce friction between the pulley and the shaft, enhancing efficiency. Additionally, surface treatments can improve corrosion resistance.

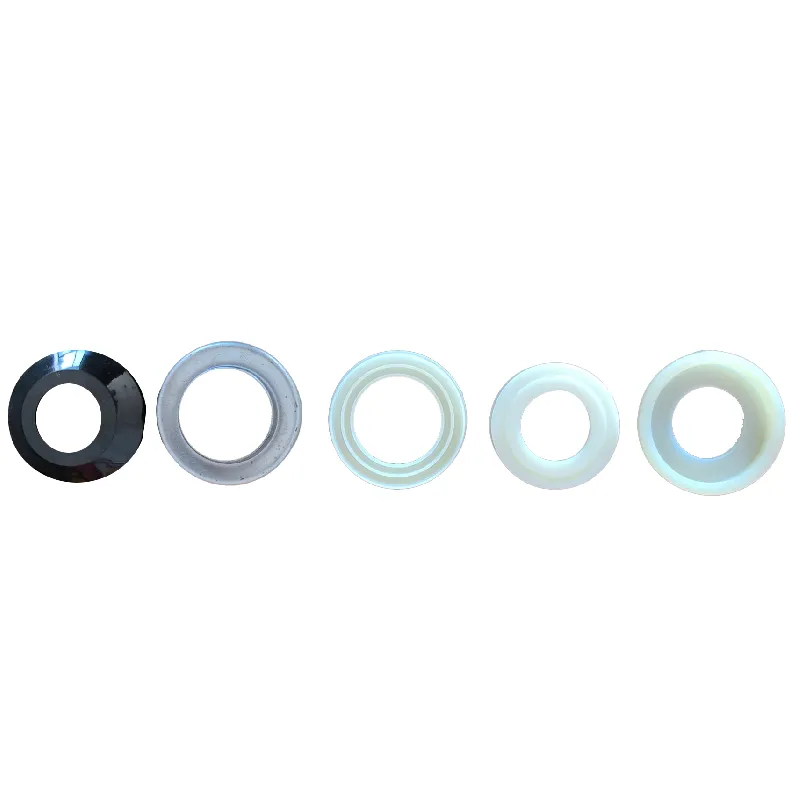

4. Coupling Mechanism The way the pulley is attached to the shaft is crucial. Common methods include keyways, set screws, or taper-lock bushes, which provide a secure attachment while allowing for ease of disassembly.

Applications

Drive pulley shafts are ubiquitous across a range of industries

1. Automotive Industry In vehicles, drive pulley shafts play a major role in the engine system, transferring power from the engine to various accessories such as the power steering pump and alternator.

2. Manufacturing and Industrial Equipment In manufacturing settings, pulley systems powered by drive shafts are used in conveyor belts, robotic arms, and machinery that require synchronized movement.

3. Elevators and Hoists Drive pulley shafts are essential in lift systems, providing controlled movement and safety for passengers and goods.

4. Entertainment and Sports In amusement parks, drive shafts are used in rides and attractions to enable movement and enhance the visitor experience.

Maintenance and Troubleshooting

To ensure optimal performance and longevity of drive pulley shafts, regular maintenance is essential. This includes

- Lubrication Proper greasing of bearings can reduce friction and avoid overheating. - Alignment Checks Misalignment can cause excessive wear, so periodic checks should be made. - Wear Inspection Regular inspections for signs of wear or damage can prevent unexpected failures.

In conclusion, the drive pulley shaft is a fundamental component in numerous mechanical systems, providing efficient power transmission and enhancing overall performance. Understanding its design features, material properties, and applications can aid engineers and technicians in selecting the right systems for their specific needs, ultimately contributing to the reliability and efficiency of machinery in various sectors. As technology continues to advance, innovations in shaft design and materials will undoubtedly improve the efficiency and capabilities of drive pulley systems, paving the way for future developments in mechanical engineering.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025