Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Drive Shaft and Pulley System for Efficient Power Transmission

Understanding Drive Pulley Shafts An Essential Component of Mechanical Systems

In various mechanical systems, drive pulley shafts play a crucial role in transmitting power and motion. This article delves into the significance, design, and applications of drive pulley shafts, outlining their importance in industrial and everyday machinery.

What is a Drive Pulley Shaft?

A drive pulley shaft is a cylindrical component that connects to a pulley, facilitating the transfer of rotational motion from one part of a machine to another. Typically constructed from sturdy materials such as steel or aluminum, these shafts are designed to withstand considerable stress and load during operation. The shaft provides a stable foundation for the pulley, enabling it to rotate smoothly and efficiently under varying conditions.

Importance in Mechanical Systems

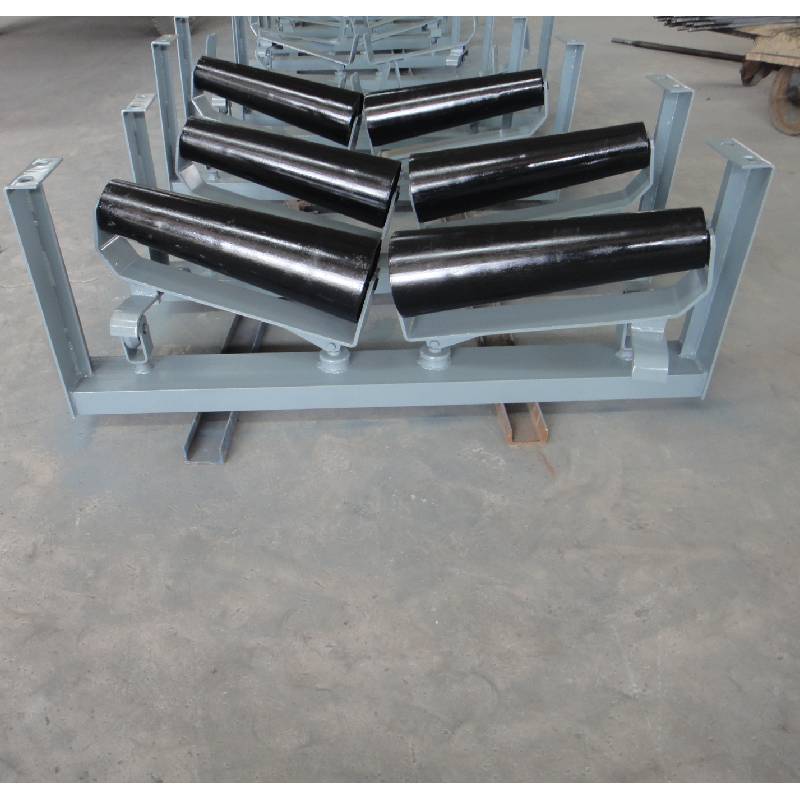

Drive pulley shafts are integral to numerous mechanical systems across various industries. They are most commonly found in conveyor systems, automotive engines, and industrial machinery. In conveyor systems, for instance, a drive pulley shaft is responsible for moving materials along a belt, ensuring smooth operation and efficient transport.

In automotive applications, these shafts connect the engine’s power output to various accessories, such as alternators and air conditioning compressors. A well-functioning drive pulley shaft not only enhances the performance of the vehicle but also contributes to the overall efficiency of the engine.

Design Considerations

drive pulley shaft

The design of a drive pulley shaft involves several critical factors to ensure optimal performance. Key considerations include the diameter of the shaft, the material used, and the method of attachment to both the pulley and the motor or other power source.

The diameter of the shaft is crucial, as it directly impacts the strength and ability to handle torque. A thicker shaft can typically withstand more force but may be heavier, which could affect the overall dynamics of the machine.

Material selection is equally important; the shaft must be durable enough to resist wear and tear over time. Steel, often treated for enhanced durability, is a common choice because of its high tensile strength and resistance to deformation.

Applications

Drive pulley shafts find applications in a variety of fields. In manufacturing, they are vital for the operation of conveyor belts, enabling the movement of products and materials through different stages of production. In agriculture, these shafts are found in combines and tractors, driving various attachments and implements.

In the entertainment industry, ride manufacturers rely on drive pulley shafts for amusement park rides and similar attractions, where safety and reliability are paramount.

Conclusion

The drive pulley shaft may seem like a simple component, but its significance in mechanical systems cannot be overstated. From automotive applications to industrial machinery, these shafts are essential for effective power transmission and operational efficiency. As technology advances, the design and materials used for drive pulley shafts will continue to evolve, further enhancing their performance and reliability in various applications. Understanding their role allows engineers and designers to create more efficient and robust systems that will meet the demands of modern machinery.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025