Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 20, 2025 08:08

Back to list

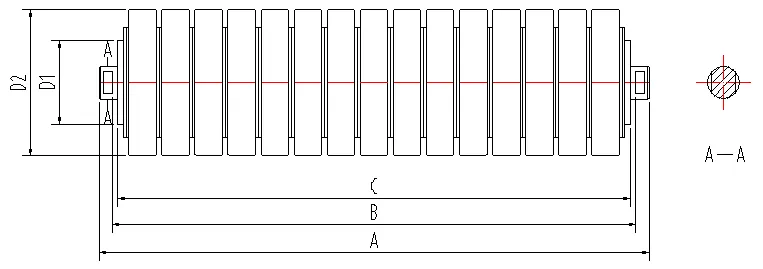

v belt drive pulley

Understanding drive pulley keys is essential for anyone involved in mechanical systems where power transmission plays a crucial role. These small yet significant components are pivotal in maintaining the integrity and functionality of mechanical assemblies. Our exploration of drive pulley keys offers a comprehensive look into their role, types, and considerations for selection, serving as an authoritative resource for industry professionals and engineers alike.

The expertise involved in correctly selecting and applying drive pulley keys reflects a deep understanding of mechanical systems and requirements. It demands not only theoretical knowledge but also practical experience to foresee potential issues related to misalignment and fatigue. Consulting authoritative resources and industry standards can provide invaluable guidance, ensuring the keys perform reliably across their intended lifespan. Trust in the quality and reliability of your drive pulley key comes from sourcing components from reputable manufacturers. Manufacturers adhering to rigorous quality standards and providing certifications demonstrate a commitment to excellence and safety. This assurance is vital as it directly impacts the maintenance and operational costs of the machinery utilizing these keys. Incorporating the right drive pulley key into your system not only enhances efficiency but also extends the life of your mechanical assemblies. Proper installation and maintenance play a crucial role in this regard. Adhering to recommended torque specifications and regularly inspecting for wear and tear can prevent breakdowns and costly repairs. This comprehensive understanding of drive pulley keys underscores their significance in enhancing the reliability and efficiency of mechanical systems. By combining hands-on experience with authoritative knowledge, one can make informed decisions essential for the seamless operation of power transmission assemblies, thereby securing both performance and safety. Engaging with experienced professionals and leveraging their expertise can significantly aid in optimizing these systems to meet specific operational needs.

The expertise involved in correctly selecting and applying drive pulley keys reflects a deep understanding of mechanical systems and requirements. It demands not only theoretical knowledge but also practical experience to foresee potential issues related to misalignment and fatigue. Consulting authoritative resources and industry standards can provide invaluable guidance, ensuring the keys perform reliably across their intended lifespan. Trust in the quality and reliability of your drive pulley key comes from sourcing components from reputable manufacturers. Manufacturers adhering to rigorous quality standards and providing certifications demonstrate a commitment to excellence and safety. This assurance is vital as it directly impacts the maintenance and operational costs of the machinery utilizing these keys. Incorporating the right drive pulley key into your system not only enhances efficiency but also extends the life of your mechanical assemblies. Proper installation and maintenance play a crucial role in this regard. Adhering to recommended torque specifications and regularly inspecting for wear and tear can prevent breakdowns and costly repairs. This comprehensive understanding of drive pulley keys underscores their significance in enhancing the reliability and efficiency of mechanical systems. By combining hands-on experience with authoritative knowledge, one can make informed decisions essential for the seamless operation of power transmission assemblies, thereby securing both performance and safety. Engaging with experienced professionals and leveraging their expertise can significantly aid in optimizing these systems to meet specific operational needs.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS