Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 28, 2025 02:16

Back to list

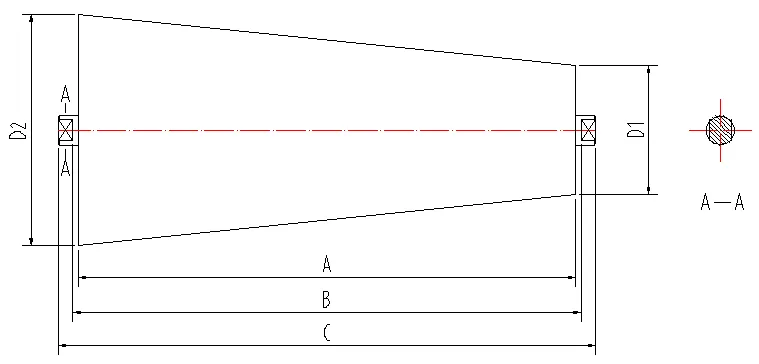

drive pulley in belt conveyor

The role of the drive pulley in a belt conveyor system is pivotal, yet often its importance gets overshadowed by its apparently simple function. Unveiling the complex mechanisms behind this critical component can provide a new perspective on its indispensability in achieving efficient material handling and optimizing overall conveyor performance.

Balancing these factors requires a comprehensive understanding of the application demands. As an expert in conveyor technology, I advocate for a precise calibration of these parameters tailored to specific operation requirements. Solutions need to be both innovative and specific, addressing unique challenges such as high humidity environments, which could affect friction, or operations requiring impeccable synchronization in multiple pulley systems. Ensuring proper installation and maintenance of drive pulleys cannot be overstated. Misalignment or inadequate tension can lead to uneven wear, reduced efficiency, and premature failure. Detailed attention during the alignment process and regular inspection schedules protect against unexpected downtimes and costly repairs. Including sophisticated monitoring technologies such as load sensors can provide real-time data on pulley performance, preemptively signaling maintenance needs before more significant issues arise. Expertise in drive pulley technology is constantly evolving with innovations aimed at reducing energy consumption and enhancing performance. The introduction of energy-efficient pulleys with advanced designs tailored for specific industrial applications highlights the ongoing commitment to sustainable practices without sacrificing operational excellence. In conclusion, the drive pulley is an integral component of belt conveyor systems. Leveraging substantial industry expertise to ensure that these components are selected, installed, and maintained with precision, ultimately contributes to increased system reliability and efficiency. Trust in a knowledgeable partner for your pulley needs can lead to considerable improvements in operational performance and is an investment in the extended and productive life of your conveyor system.

Balancing these factors requires a comprehensive understanding of the application demands. As an expert in conveyor technology, I advocate for a precise calibration of these parameters tailored to specific operation requirements. Solutions need to be both innovative and specific, addressing unique challenges such as high humidity environments, which could affect friction, or operations requiring impeccable synchronization in multiple pulley systems. Ensuring proper installation and maintenance of drive pulleys cannot be overstated. Misalignment or inadequate tension can lead to uneven wear, reduced efficiency, and premature failure. Detailed attention during the alignment process and regular inspection schedules protect against unexpected downtimes and costly repairs. Including sophisticated monitoring technologies such as load sensors can provide real-time data on pulley performance, preemptively signaling maintenance needs before more significant issues arise. Expertise in drive pulley technology is constantly evolving with innovations aimed at reducing energy consumption and enhancing performance. The introduction of energy-efficient pulleys with advanced designs tailored for specific industrial applications highlights the ongoing commitment to sustainable practices without sacrificing operational excellence. In conclusion, the drive pulley is an integral component of belt conveyor systems. Leveraging substantial industry expertise to ensure that these components are selected, installed, and maintained with precision, ultimately contributes to increased system reliability and efficiency. Trust in a knowledgeable partner for your pulley needs can lead to considerable improvements in operational performance and is an investment in the extended and productive life of your conveyor system.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS