Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu drive pulley for sale

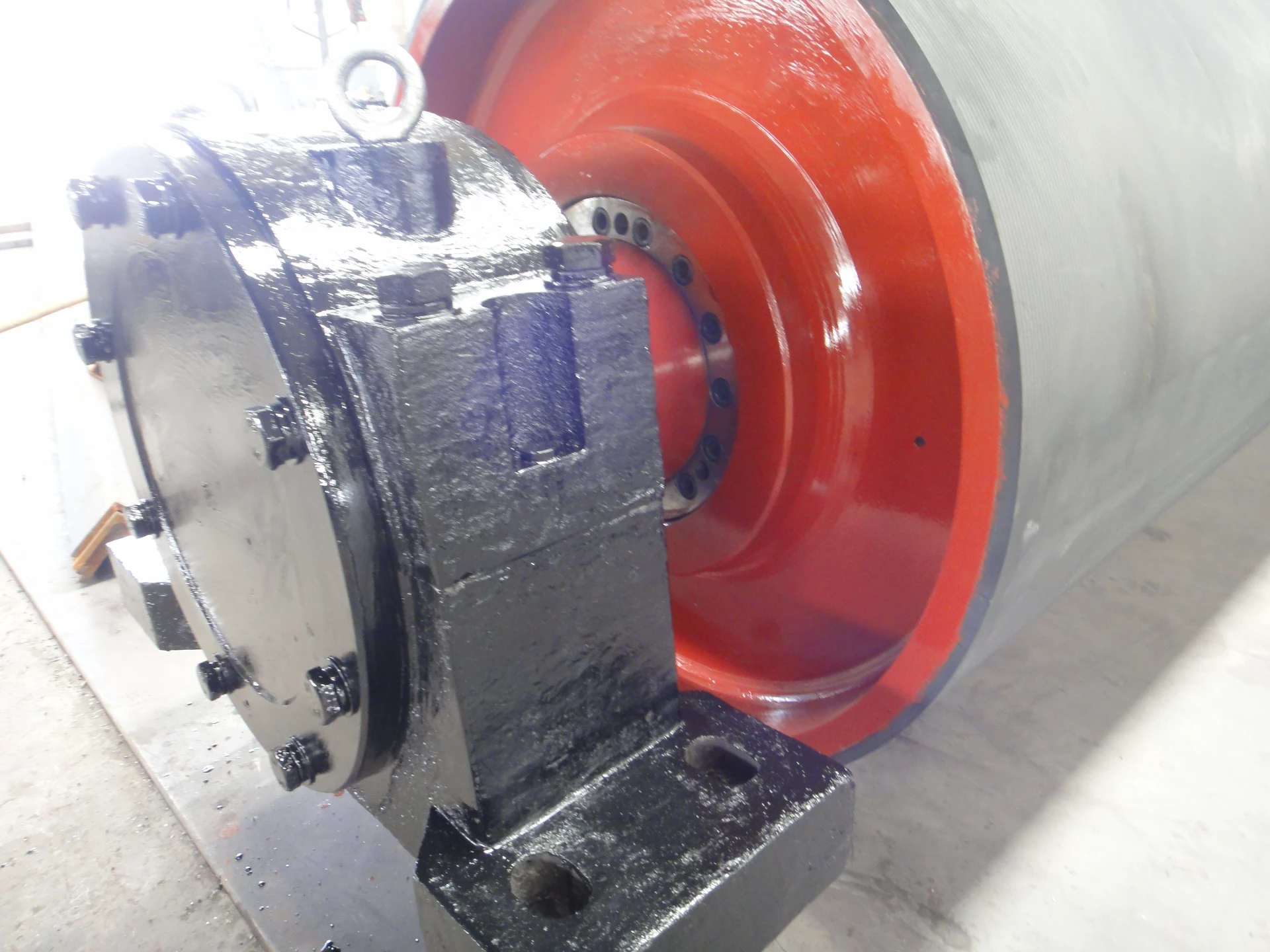

Drive Pulley for Sale The Essential Component for Your Machinery Needs

In the world of mechanics, drive pulleys play a pivotal role in the efficient operation of various machinery. These simple yet essential components are indispensable in the transmission of power, ensuring that machines operate smoothly and effectively. If you are in the market for high-quality drive pulleys, you have come to the right place. Here, we will discuss the significance of drive pulleys, the different types available, and what to consider when purchasing them.

Understanding Drive Pulleys

A drive pulley is a wheel or a cylinder on an axle or shaft that is designed to transmit power through a belt or cable. As the drive pulley rotates, it engages the belt that connects it to another pulley, ultimately driving the movement of machinery components. This mechanism is widely utilized in various industries, including manufacturing, automotive, and agricultural sectors, showcasing the versatility and reliability of drive pulleys.

Types of Drive Pulleys

Drive pulleys come in various types, each designed to fulfill specific functions. The primary types include

1. Flat Pulleys These are the simplest form of pulleys, typically used with flat belts. They are ideal for low-speed applications and can be found in basic machinery setups.

2. V-Pulleys Designed with a V-shaped groove, these pulleys are tailored for use with V-belts. They provide better grip and reduce slippage, making them suitable for higher-speed applications.

3. Sheave Pulleys Often used in conjunction with ropes or cables, sheave pulleys are essential in lifting applications, such as cranes and elevators.

4. Sprocket Pulleys These pulleys connect with chains and are commonly found in bicycles and motorcycles, providing a robust solution for power transmission in high-load situations.

drive pulley for sale

Factors to Consider When Buying Drive Pulleys

When looking to purchase drive pulleys, several factors should be taken into account to ensure you select the right component for your needs

1. Material Drive pulleys are made from various materials, ranging from aluminum and steel to plastic. The choice of material will depend on the application, load, and environmental conditions.

2. Size and Dimensions It's crucial to choose the correct size for your machinery. Measure the diameter and width of the pulley and ensure it fits well with your existing setup.

3. Type of Belt Consider the type of belt you will be using. Different pulleys are compatible with different belts, so knowing your belt specifications will help you make an informed decision.

4. Load Capacity Ensure the pulley you select can handle the expected load. Check the manufacturer's specifications for weight limits and performance ratings.

5. Brand Reputation Opt for reputable brands known for quality and durability. A well-manufactured pulley can make a significant difference in machine performance and longevity.

6. Price and Warranty Price is always a consideration in purchasing decisions. Compare prices from different suppliers, but also ensure that you are receiving a warranty for your investment.

Conclusion

Drive pulleys are integral components that aid in the seamless functioning of various machines across multiple industries. With a variety of types and options available, understanding your specific needs is essential when making a purchase. By considering factors such as material, size, belt type, load capacity, and brand reputation, you can find the perfect drive pulley for your requirements. Explore our range of drive pulleys for sale today and invest in the reliability and efficiency of your machinery.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025