Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu drive belt idler

Understanding Drive Belt Idlers Their Importance and Functionality

Drive belt idlers are a crucial component in the mechanics of various machines, particularly in automotive and industrial applications. They play a significant role in ensuring smooth operation, efficient power transmission, and overall longevity of the belts they support. This article will delve into the nature of drive belt idlers, their functions, components, and maintenance, underscoring their importance in the broader scope of machinery and vehicle performance.

What is a Drive Belt Idler?

A drive belt idler is a pulley that guides or supports a drive belt within an engine or a machinery system. It is typically found in systems that utilize serpentine belts or V-belts. The idler pulley may not transmit power directly, but it helps maintain belt tension and proper alignment, which is essential for the effective operation of the belt-driven components.

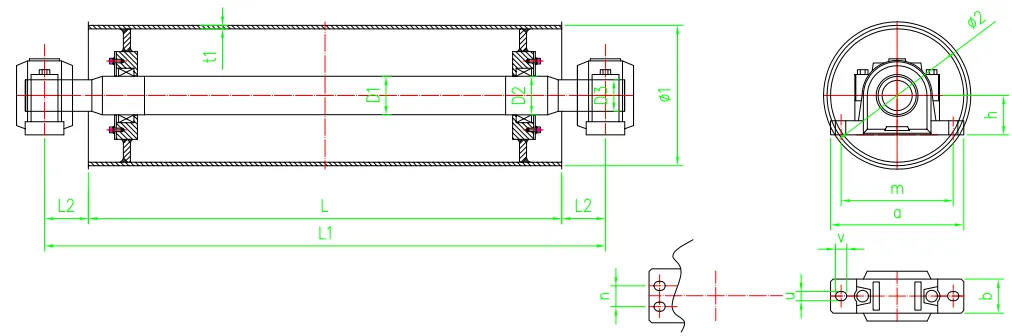

Components of Drive Belt Idlers

Drive belt idlers generally consist of two main parts the pulley itself and the bearing that allows it to rotate smoothly. The pulley is usually made from durable materials such as steel or composite plastics to withstand wear and tear. The bearing can be either sealed or open, with sealed bearings typically offering better protection from dirt and debris, consequently increasing their lifespan.

Some idler pulleys also incorporate an adjustment mechanism that allows for the tension of the belt to be modified easily. This is crucial for maintenance and repair, as proper tension is vital for ensuring efficient operation and reducing the wear on both the belt and the idler.

Functions of Drive Belt Idlers

1. Tension Maintenance One of the primary functions of drive belt idlers is to maintain the appropriate tension in the belt. Insufficient tension can lead to belt slippage, reduced efficiency, and possible damage to both the belt and the driven components.

2. Belt Alignment Idlers help in aligning the belt properly within the system. Misalignment can lead to uneven wear, noise, and potential failure of the system; therefore, idlers are positioned strategically to guide the belt.

drive belt idler

3. Reducing Vibration Drive belt idlers help alleviate some of the vibrations that may occur during operation. They provide a smoother path for the belt, ensuring quieter performance and reducing wear on associated components.

4. Supporting Other Components In some applications, the idler pulley may also serve a dual purpose, supporting other pulleys or components that are critical to the drivetrain's performance.

Maintenance of Drive Belt Idlers

Regular maintenance of drive belt idlers is essential for the longevity of both the idlers themselves and the belts they support. Here are some key maintenance tips

- Inspection Regularly inspect the condition of the idler pulley for any signs of wear, such as cracking, fraying, or misalignment. Early detection can prevent more severe issues down the line.

- Tension Checks Ensure that the belt tension is within the manufacturer's specifications. If the tension is too high or low, adjust it accordingly to prolong the life of both the belt and the idler.

- Lubrication Depending on the type of bearing used, it may be necessary to lubricate the idler pulleys periodically. Check manufacturers' guidelines regarding lubrication to avoid damaging the components.

- Replacement Idler pulleys will eventually wear out, and knowing when to replace them is critical. Signs that replacement is necessary include excessive noise, vibration, or visible damage.

Conclusion

Drive belt idlers are more than just passive components; they play an essential role in the functionality, efficiency, and reliability of machinery and vehicle systems. By understanding their functions, components, and maintenance needs, operators can ensure optimal performance and extend the life of drive belts and associated machinery. Regular checks and proper care of these components can prevent costly repairs and ensure smooth operations, making drive belt idlers a vital aspect of any mechanical system that relies on belt-driven technology.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025