Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

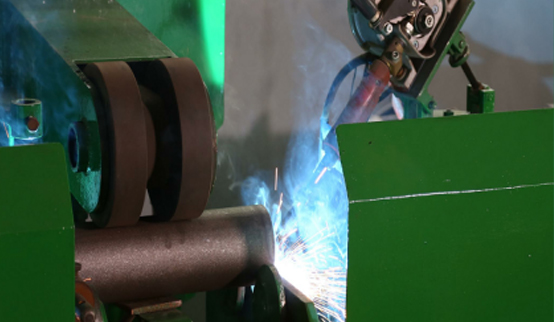

Zulu designed conveyor components

Designed Conveyor Components Enhancing Efficiency in Material Handling

In the realm of industrial operations, efficient material handling is a critical factor that can significantly impact productivity. One of the essential components of any material handling system is the conveyor. Designed conveyor components play a vital role in optimizing the movement of goods within warehouses, manufacturing plants, and distribution centers. In this article, we will explore the key elements of designed conveyor components, their types, advantages, and the latest innovations that are shaping their future.

Understanding Conveyor Components

A conveyor system comprises various components that work together to transport materials from one point to another. The primary components of a conveyor system include

1. Belts The belt is the most visible part of a conveyor system. It is responsible for carrying materials from one location to another. Conveyors can utilize different types of belts, including rubber, modular plastic, and steel, depending on the application and the nature of the materials being handled.

2. Rollers These are cylindrical components that support the conveyor belt and facilitate its movement. Rollers can be powered or non-powered and come in various sizes to accommodate different belt widths and loads.

3. Frames The conveyor frame provides structural support and houses the other components. Frames can be constructed from various materials, such as steel or aluminum, and can be designed to fit the specific requirements of the application.

4. Drive Units These are critical for the operation of the conveyor system. Drive units can include motors, gears, and pulleys that provide the necessary force to move the conveyor belt and the materials it carries.

5. Idlers These are components that support the belt and help maintain its tension. Idlers play a crucial role in ensuring smooth operation and reducing wear and tear on the belt.

6. Sensors and Controls Modern conveyor systems increasingly integrate sensors and controls that enable automation, monitoring, and optimization of the material handling process.

Types of Conveyor Systems

Conveyor systems come in various types, each designed for specific applications. Some common types include

- Belt Conveyors Ideal for transporting bulk materials and packages over flat surfaces.

- Roller Conveyors Used for transporting items on rollers, allowing for manual or powered movement.

- Chain Conveyors Suitable for heavy-duty applications, particularly in industries like automotive and heavy manufacturing.

- Overhead Conveyors Used for moving items along overhead tracks, freeing up floor space.

designed conveyor components

Advantages of Designed Conveyor Components

Investing in designed conveyor components offers numerous benefits, including

1. Enhanced Efficiency Well-designed conveyor systems minimize manual handling, streamline operations, and improve overall efficiency in material flow.

2. Increased Safety Automated conveyor systems reduce the risk of worker injury by minimizing the need for manual lifting and carrying.

3. Versatility With various design options available, conveyor systems can be tailored to fit specific needs across different industries.

4. Reduced Downtime Designed components are often built for durability, which means less frequent maintenance and reduced downtime for repairs.

5. Scalability As businesses grow, so do their operational needs. Conveyor systems can be expanded or modified to accommodate increased production demands.

Innovations in Conveyor Technology

The conveyor industry continues to evolve, with several innovations enhancing the functionality and efficiency of designed conveyor components. Some notable trends include

- Smart Conveyors The integration of IoT technology allows for real-time monitoring and data analysis, enabling proactive maintenance and process optimization.

- Modular Systems Modular conveyor designs allow for easy reconfiguration and scalability, making it possible to adapt to changing production needs quickly.

- Eco-Friendly Materials Manufacturers are increasingly using sustainable materials and energy-efficient components to reduce the environmental impact of conveyor systems.

- Robotics and Automation The synergy between conveyors and robotic systems is paving the way for automated warehouses, enhancing efficiency, and reducing labor costs.

Conclusion

Designed conveyor components are pivotal in modern industrial operations, playing a crucial role in enhancing material handling efficiency. With a variety of types available, each tailored for specific tasks, and ongoing innovations pushing the boundaries of technology, businesses can significantly boost their productivity and operational capabilities. Investing in well-designed conveyor systems not only meets current needs but also prepares companies for future challenges.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025