Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu cushion roller

The Importance and Functionality of Cushion Rollers in Modern Applications

Cushion rollers are an essential component in various industries, providing critical support and functionality to a wide range of applications. From manufacturing and logistics to personal fitness, the design and utility of cushion rollers have evolved significantly to meet the demands of modern technology and consumer needs. This article explores the importance, functionality, and versatility of cushion rollers, highlighting their role in different sectors.

What are Cushion Rollers?

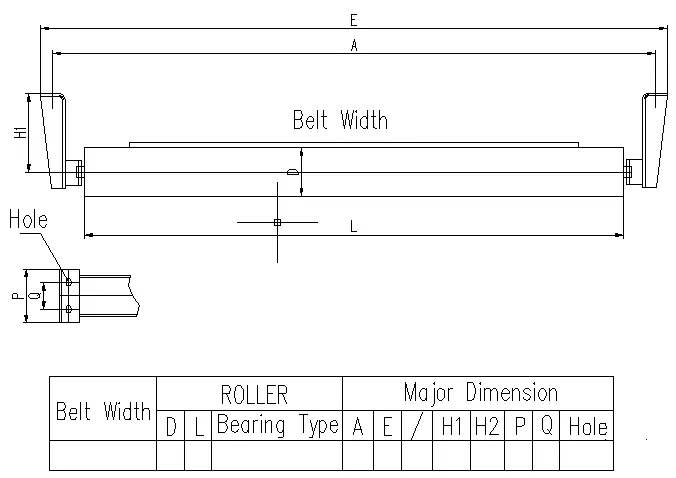

Cushion rollers refer to cylindrical devices designed to carry or support loads while allowing for smooth movement. These rollers are often made from materials that provide a certain degree of cushioning, such as rubber or other polymer composites. This cushioning effect enables the roller to absorb shock, reduce vibrations, and protect sensitive components in machinery. Cushion rollers are widely utilized in various applications, including conveyor systems, automotive production lines, and even in fitness equipment.

Applications in Industry

One of the most prevalent uses of cushion rollers is in conveyor systems. In manufacturing and logistics, conveyance is a critical process. Cushion rollers facilitate the smooth transition of products along conveyor belts, helping to prevent damage during transportation. The cushioning effect helps to minimize the impact of heavy loads, reducing the risk of product breakage and contributing to efficient operations.

Moreover, cushion rollers are extensively used in the automotive industry. They play a vital role in assembly lines, where they support heavy car parts moving through various stages of production. The integration of cushion rollers in these lines helps to ensure a steady flow of materials while reducing wear and tear on both the rollers and the machinery. By providing a stable and smooth surface for movement, cushion rollers enhance the efficiency and safety of automotive manufacturing processes.

Enhancements in Design and Material

cushion roller

The design and materials of cushion rollers have significantly evolved over the years. Manufacturers now employ advanced materials that provide superior durability and resilience. For example, high-grade polyurethane and thermoplastic elastomers are commonly used due to their excellent shock-absorbing properties and resistance to wear and tear.

Additionally, many modern cushion rollers feature innovative designs that enhance functionality. Some rollers come with built-in bearings or other mechanisms that allow for even smoother movement, reducing the friction typically associated with traditional rollers. This advancement not only improves performance but also extends the lifespan of the equipment in which they are used.

Importance in Personal Fitness

Beyond industrial applications, cushion rollers have found a place in personal fitness and rehabilitation. Foam rollers, which are a type of cushion roller, are popular among physical therapists and fitness enthusiasts alike. These rollers are used for myofascial release, helping to alleviate muscle soreness and improve flexibility. The cushioning material provides a gentle surface for individuals to roll on, effectively targeting tight muscles and relieving tension.

Using foam rollers can promote recovery after intense workouts, making them an invaluable tool for athletes. They are widely available in various sizes and densities, catering to different user needs and preferences. Incorporating cushion rollers into personal fitness routines can lead to better performance and reduced risk of injury, showcasing their versatility beyond industrial settings.

Conclusion

Cushion rollers represent a remarkable intersection of engineering and functionality, significantly impacting various sectors from manufacturing to personal fitness. Their ability to absorb shock and reduce vibrations not only protects equipment and products but also enhances operational efficiency. As technology continues to advance, we can expect further innovations in the design and application of cushion rollers, solidifying their importance in both industrial and personal contexts. The evolution of cushion rollers illustrates how a simple yet effective component can lead to substantial improvements across diverse industries, ultimately contributing to enhanced productivity and well-being.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025