Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

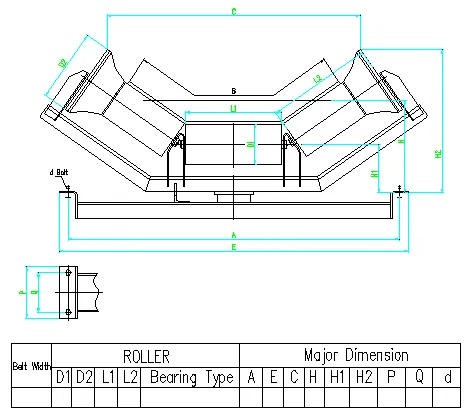

Zulu cushion roller

The Role of Cushion Rollers in Modern Manufacturing Processes

Cushion rollers are an essential component in various industrial applications, playing a vital role in enhancing productivity and efficiency in manufacturing processes. These specialized rollers, designed to absorb shock and reduce friction, are increasingly embraced in situations requiring the smooth handling of materials. This article delves into the significance, types, and advantages of cushion rollers, highlighting their contribution to contemporary manufacturing landscapes.

Understanding Cushion Rollers

Cushion rollers are typically constructed from resilient materials that can absorb impacts and sustain heavy loads. They are primarily utilized for conveying items along assembly lines, packaging systems, and transportation mechanisms within factories. The cushioning effect helps in lowering vibration and shock, thereby extending the lifespan of both the roller and the machinery it supports.

These rollers come in various configurations, often customized to meet the specific needs of particular industries. For instance, some cushion rollers might be designed with softer surfaces to handle delicate materials, while others might feature more robust materials for heavy-duty applications.

Types of Cushion Rollers

1. Polyurethane Cushion Rollers Known for their durability and resistance to wear, polyurethane cushion rollers are extensively utilized in industries such as automotive and packaging. Their ability to withstand harsh environmental conditions makes them suitable for outdoor use.

2. Rubber Cushion Rollers These rollers provide excellent traction and grip, making them ideal for applications where slippage could be a concern. Their elasticity helps in absorbing shocks effectively, ensuring that products are conveyed without damage.

3. Spring-loaded Cushion Rollers Featuring internal spring mechanisms, these rollers automatically adjust to varying loads and heights. They are particularly valuable in dynamic environments where the height of the items being conveyed may fluctuate.

cushion roller

Advantages of Using Cushion Rollers

The implementation of cushion rollers brings several advantages to manufacturing processes

1. Enhanced Product Protection One of the primary benefits of cushion rollers is their ability to minimize damage to fragile products during handling and transportation. By absorbing shocks and vibrations, cushion rollers help maintain product integrity.

2. Increased Lifespan of Equipment The cushioning effect reduces wear and tear on machinery, contributing to longer operational lifespans and fewer maintenance checks. This leads to lower replacement costs and improved overall efficiency.

3. Improved Efficiency Cushion rollers enhance the flow of goods through production lines, allowing for a more streamlined operation. With their ability to accommodate various loads and package shapes, they facilitate swift transitions between different stages of manufacturing.

4. Sound Dampening In addition to their mechanical benefits, cushion rollers can also play a role in reducing noise levels within manufacturing environments. The absorbent materials can help dampen sounds produced during the movement of goods, creating a more conducive working atmosphere.

5. Customization Options With advancements in material science, cushion rollers can be tailored for specific applications. Manufacturers can select the appropriate materials and design features that align with their unique operational needs.

Conclusion

Cushion rollers are an indispensable asset in the realm of manufacturing, marrying functionality with innovation. Their ability to protect products, enhance efficiency, and extend the life of equipment makes them a critical component across diverse industries. As manufacturing technologies continue to evolve, the role of cushion rollers will likely expand further, underscoring their importance in the quest for optimized production processes and sustained growth. In an increasingly competitive marketplace, companies that invest in high-quality cushion rollers are likely to reap the rewards of improved operational performance and product quality.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025