Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

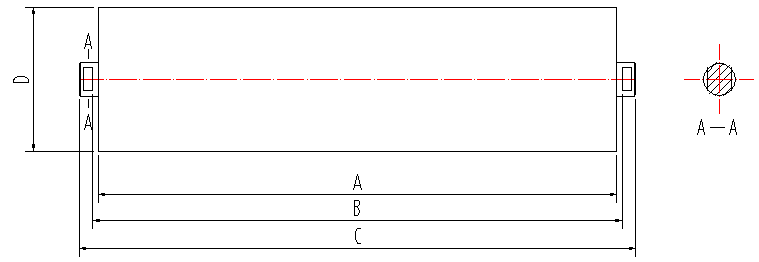

Zulu cushion roller

The Importance of Cushion Roller in Material Handling

In the realm of material handling and conveyor systems, the cushion roller plays a pivotal role. These specially designed rollers are essential for supporting conveyor belts and facilitating the smooth transport of goods in various industries. Understanding the significance of cushion rollers can help businesses improve efficiency and reduce wear and tear on their equipment.

Cushion rollers, as the name suggests, are built with a cushioning mechanism that absorbs shock and reduces vibrations during material movement. This feature is critical, especially in high-speed conveyor systems where heavy loads are transported. By mitigating the impact forces generated during loading and unloading processes, cushion rollers help maintain the integrity of both the conveyor belt and the materials being handled. As a result, they prolong the lifespan of the entire conveyor system, ultimately leading to cost savings for businesses.

Moreover, the flexibility provided by cushion rollers allows them to adapt to various operational conditions

. They are often made from durable materials such as rubber or polyurethane, which offer excellent resilience and longevity. This adaptability is crucial in environments where loads are uneven or when materials are subjected to frequent changes in direction. When properly integrated into a conveyor system, cushion rollers can optimize the flow of materials while minimizing the risk of jams or product damage.cushion roller

In addition to their performance benefits, cushion rollers also contribute to workplace safety. By absorbing shocks and preventing sudden jerks in the conveyor motion, they help create a more stable working environment. This stability is essential for reducing the risk of accidents, such as falls or equipment malfunctions, which can lead to costly downtime and potential injuries.

Routine maintenance of cushion rollers is equally important. Regular inspections and timely replacements can ensure optimal performance and safety. Businesses should also consider investing in high-quality cushion rollers from reputable suppliers to maximize benefits.

In conclusion, cushion rollers are an integral component of modern material handling systems. By enhancing equipment longevity, improving operational efficiency, and increasing workplace safety, they play a crucial role in supporting business objectives. As industries continue to evolve, the demand for advanced material handling solutions will only increase, making the cushion roller a vital investment for companies aiming to stay competitive in today’s fast-paced market.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025