Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor wing pulley

The Importance of Conveyor Wing Pulleys in Material Handling Systems

Conveyor systems play a crucial role in various industries, facilitating the efficient movement of materials. Among the essential components of these systems are conveyor wing pulleys, which significantly enhance the operational efficiency and longevity of the conveyor setup. This article explores the function, benefits, and considerations associated with conveyor wing pulleys in material handling systems.

What are Conveyor Wing Pulleys?

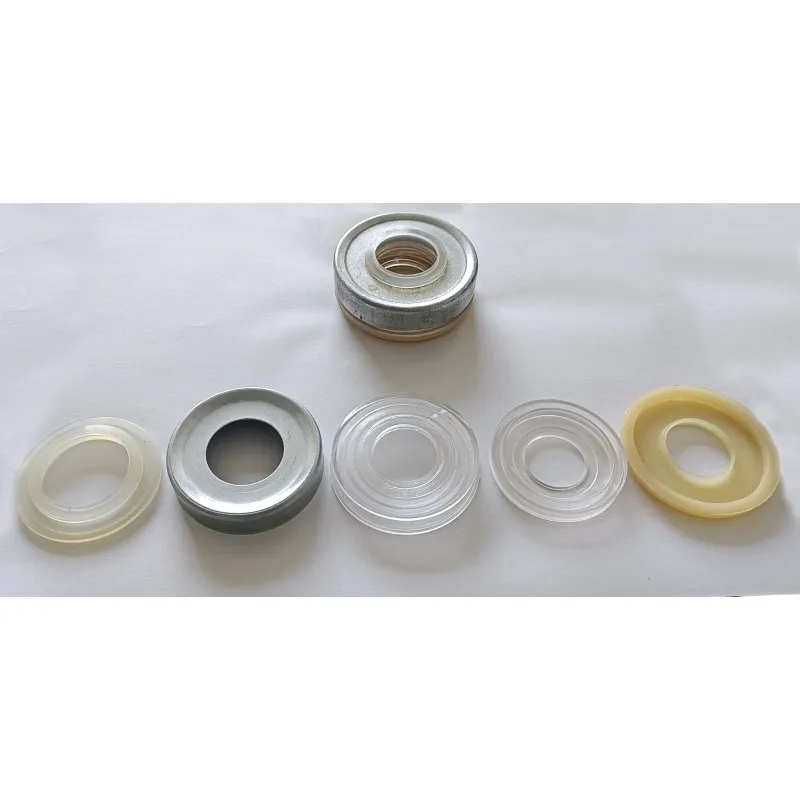

Conveyor wing pulleys are specialized pulleys designed with angled flanges that extend from the main body of the pulley. These flanges, often known as wings, serve several purposes, primarily aimed at guiding and supporting the conveyor belt during operation. Wing pulleys can be seen as the end pulleys in conveyor systems, acting as a key point for belt tension and alignment.

Key Functions of Wing Pulleys

1. Belt Performance The unique design of wing pulleys helps maintain belt tension, ensuring optimal contact between the belt and pulley. This is critical for reducing friction and wear on the belt, enabling smoother operation.

2. Material Discharge Wing pulleys facilitate the efficient discharge of material from the conveyor system. The angled flanges help direct bulk materials off the belt and minimize spillage, which can lead to material loss and increased maintenance costs.

3. Self-Cleaning Capability One of the standout features of wing pulleys is their self-cleaning ability. The design minimizes the accumulation of debris and material on the pulley surface, reducing downtimes due to clogging, which is common in conventional pulleys.

4. Durability and Reliability Constructed from robust materials, wing pulleys are built to withstand the harsh conditions typical in conveyor environments. Their resilience against wear and tear makes them a reliable choice for long-term use.

Benefits of Using Conveyor Wing Pulleys

1. Enhanced Efficiency By ensuring consistent belt tracking and alignment, wing pulleys contribute to the overall efficiency of the conveyor system. This leads to improved throughput and productivity.

conveyor wing pulley

2. Reduced Maintenance Costs The self-cleaning feature minimizes material buildup, which means fewer maintenance interventions are needed to keep the conveyor system running smoothly. This not only reduces labor costs but also extends the lifespan of other components in the system.

3. Versatility Wing pulleys come in various sizes and designs, allowing them to be used in a wide range of applications, from heavy-duty mining operations to lighter industrial uses. This adaptability makes them an appealing option for diverse material handling needs.

4. Cost-Effectiveness While the initial investment in high-quality wing pulleys may be higher, the long-term savings gained from reduced maintenance, increased durability, and enhanced efficiency make them a cost-effective choice.

Considerations When Choosing Wing Pulleys

When selecting conveyor wing pulleys, several factors should be taken into account

1. Material Compatibility Ensure that the pulley material is suitable for the type of material being transported. The right material choice impacts both performance and durability.

2. Environmental Conditions Consider the operational environment, such as exposure to chemicals, extreme temperatures, or wet conditions, to choose a pulley that can withstand such factors.

3. Load Capacity Assess the weight and type of loads the conveyor will handle to choose wing pulleys that meet or exceed the necessary specifications.

4. Installation and Maintenance Needs Evaluate the ease of installation and ongoing maintenance requirements to ensure that the chosen pulleys fit well within the operational workflow.

Conclusion

Conveyor wing pulleys are integral components of efficient material handling systems, providing a combination of performance, durability, and cost-effectiveness. By understanding their functions and benefits, businesses can enhance their conveyor operations, ultimately leading to increased productivity and reduced operational costs. As industries continue to evolve, the role of such specialized components becomes increasingly vital, ensuring that material handling remains efficient and sustainable.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025