Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

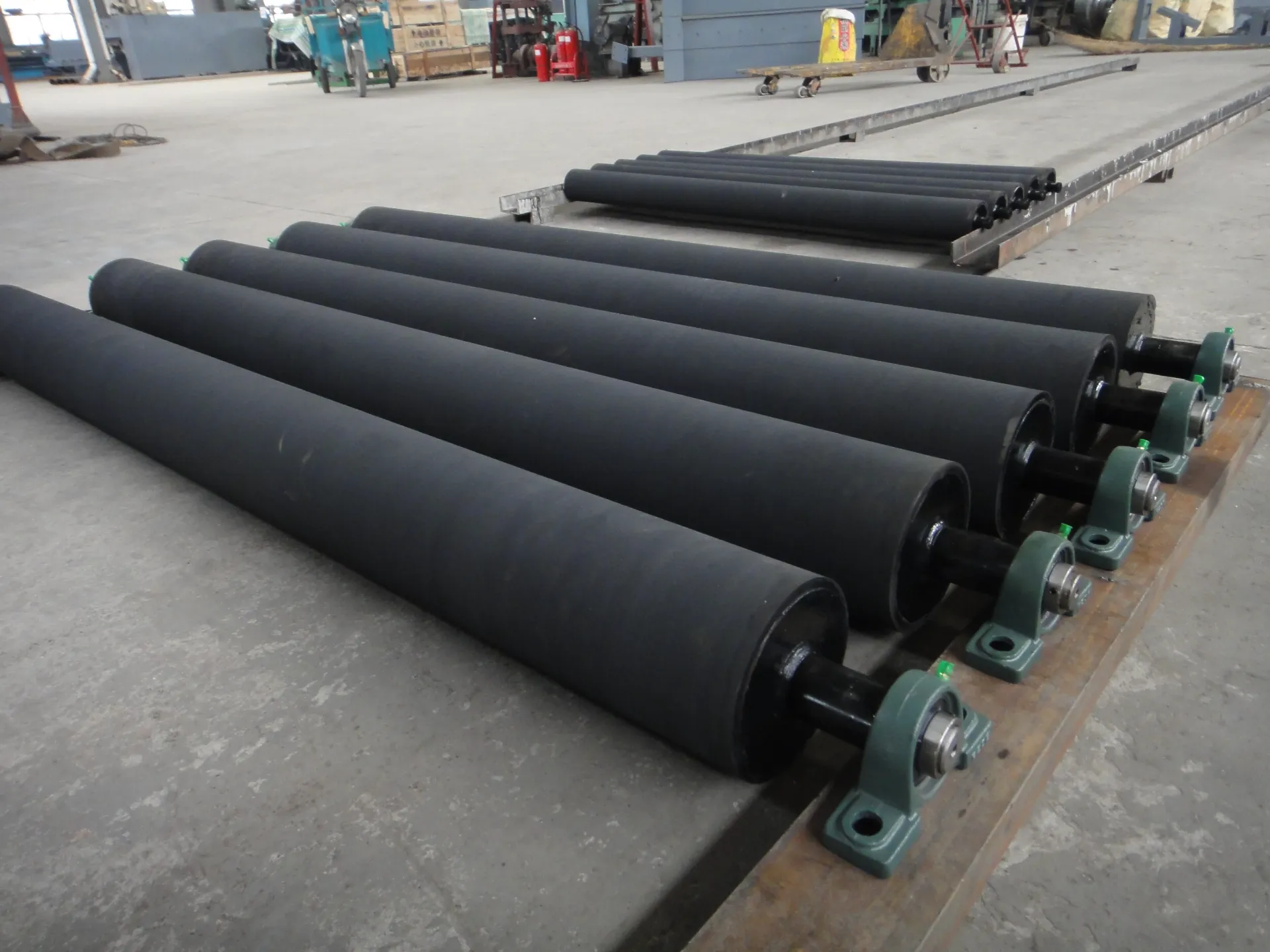

Zulu conveyor take up assembly

Understanding Conveyor Take-Up Assemblies

Conveyor systems are an integral part of many industrial operations, serving to transport materials efficiently within manufacturing and processing facilities. A critical component of these systems is the conveyor take-up assembly, which plays a significant role in maintaining the optimal performance and longevity of conveyor belts. In this article, we will delve into the purpose, types, and maintenance considerations of conveyor take-up assemblies.

The Purpose of Conveyor Take-Up Assemblies

The primary function of a conveyor take-up assembly is to manage the tension of the conveyor belt. Proper tension is essential for several reasons. It ensures that the belt runs smoothly, reducing the risk of slippage and potential damage to the system. Furthermore, correct tension minimizes wear and tear on both the belt and the conveyor components, thereby extending service life and reducing downtime.

Additionally, take-up assemblies help compensate for belt stretch that naturally occurs over time due to regular use and the weights of the materials being transported. As the belt stretches, the take-up assembly can adjust the belt length, maintaining consistent tension and performance across the system.

Types of Conveyor Take-Up Assemblies

Conveyor take-up assemblies can be categorized into two main types fixed take-up and moveable take-up assemblies.

1. Fixed Take-Up Assembly In a fixed take-up, the position of the pulleys or rollers remains static, and adjustments to belt tension must be made manually. This type is generally simpler and less expensive; however, it may require more frequent adjustments and oversight.

2. Moveable Take-Up Assembly This type features a mechanism that allows the take-up to move, usually via a screw or hydraulic system, automatically or semi-automatically adjusting the tension as the belt wears or stretches. Moveable take-ups are often considered more efficient and less labor-intensive since they minimize the need for manual adjustments and can respond to changes in tension more dynamically.

conveyor take up assembly

Maintenance of Conveyor Take-Up Assemblies

Maintaining a conveyor take-up assembly is essential to ensure the overall functionality and safety of the conveyor system

. Regular maintenance includes the following tasks- Alignment Checks Ensure that the conveyor belt and take-up assembly are properly aligned. Misalignment can lead to uneven wear, increased friction, and potential failures.

- Tension Adjustment Periodically check and adjust the tension of the conveyor belt as necessary. This can prevent slippage and prolong the lifespan of both the belt and the conveyor components.

- Lubrication Keeping the moving parts of the take-up assembly lubricated is critical for reducing friction and wear. Follow the manufacturer’s recommendations regarding the type and frequency of lubrication.

- Visual Inspections Regularly inspect the take-up assembly for signs of wear, damage, or misalignment. Look for any loose components, cracks, or abnormal wear patterns on the belt itself.

- Monitoring Performance Keep an eye on how the conveyor performs over time. Any unusual noises, vibrations, or operational issues should be investigated promptly to prevent larger problems that could lead to costly downtime.

Conclusion

The conveyor take-up assembly is a vital component of any conveyor system, ensuring that the belt operates efficiently and sustainably over its lifespan. Understanding the types of take-up assemblies and adhering to a regular maintenance schedule can help improve operational efficiency, reduce downtime, and extend the service life of conveyor systems. By investing time and resources into the proper functioning of take-up assemblies, businesses can pave the way for smoother operations and heightened productivity in their material handling processes.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025