Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Mar . 04, 2025 10:24

Back to list

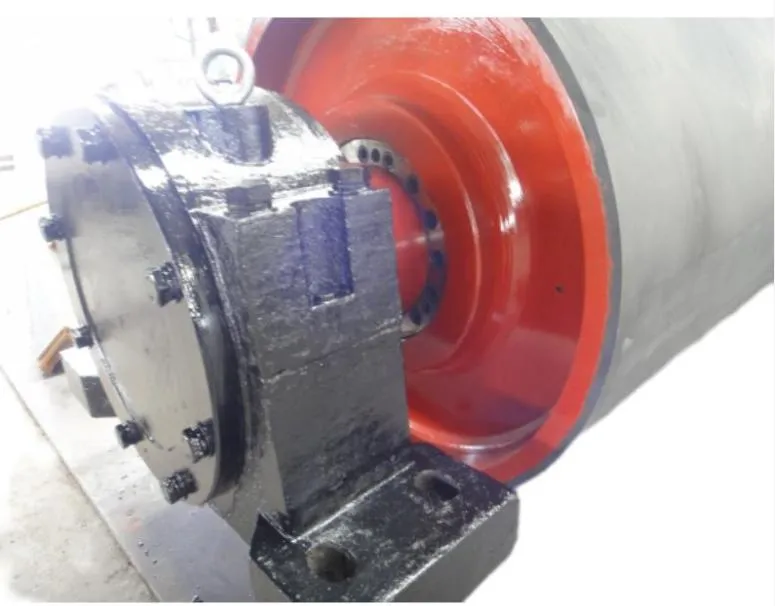

Slagging Pulley(Heavy Duty)

In the industrial realm, conveyor tail drums are indispensable components, serving pivotal roles in ensuring the smooth functioning of conveyor systems. These systems thrive across diverse sectors, including mining, manufacturing, and logistics—industries that demand high efficiency and reliability.

Authoritativeness in this field is demonstrated by commitment to adhering to industry standards and certifications. Top manufacturers often align their production processes with internationally recognized standards such as ISO 9001. Such certification not only assures product quality but also underscores a company's dedication to continual improvement and systematic quality management. Furthermore, manufacturers often invest in research and development, pushing the boundaries of conveyor technology and setting industry benchmarks. Trustworthiness is the cornerstone of long-term industrial partnerships. Leading companies build trust by offering comprehensive after-sales support, including installation guidance, maintenance services, and readily available spare parts. Customer-centric policies ensure that clients receive prompt assistance, minimizing any potential disruptions. Testimonials and case studies often accompany product listings, providing prospective buyers with insights into past performance and customer satisfaction. In conclusion, the choice of a conveyor tail drum should be driven by a considerations of experience, expertise, authoritativeness, and trustworthiness. An informed decision can significantly enhance the operational efficiency of your conveyor system, reduce downtime, and improve output consistency. As the industrial landscape evolves, so too does the technology underpinning conveyor systems, making it essential to select a partner who not only understands current demands but is also poised to meet future challenges. Opt for trusted manufacturers that offer tailor-made solutions built on a foundation of proven experience and technological expertise. Such a decision will yield dividends in performance, reliability, and peace of mind in a rapidly progressing industrial age.

Authoritativeness in this field is demonstrated by commitment to adhering to industry standards and certifications. Top manufacturers often align their production processes with internationally recognized standards such as ISO 9001. Such certification not only assures product quality but also underscores a company's dedication to continual improvement and systematic quality management. Furthermore, manufacturers often invest in research and development, pushing the boundaries of conveyor technology and setting industry benchmarks. Trustworthiness is the cornerstone of long-term industrial partnerships. Leading companies build trust by offering comprehensive after-sales support, including installation guidance, maintenance services, and readily available spare parts. Customer-centric policies ensure that clients receive prompt assistance, minimizing any potential disruptions. Testimonials and case studies often accompany product listings, providing prospective buyers with insights into past performance and customer satisfaction. In conclusion, the choice of a conveyor tail drum should be driven by a considerations of experience, expertise, authoritativeness, and trustworthiness. An informed decision can significantly enhance the operational efficiency of your conveyor system, reduce downtime, and improve output consistency. As the industrial landscape evolves, so too does the technology underpinning conveyor systems, making it essential to select a partner who not only understands current demands but is also poised to meet future challenges. Opt for trusted manufacturers that offer tailor-made solutions built on a foundation of proven experience and technological expertise. Such a decision will yield dividends in performance, reliability, and peace of mind in a rapidly progressing industrial age.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS