Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 14, 2025 06:48

Back to list

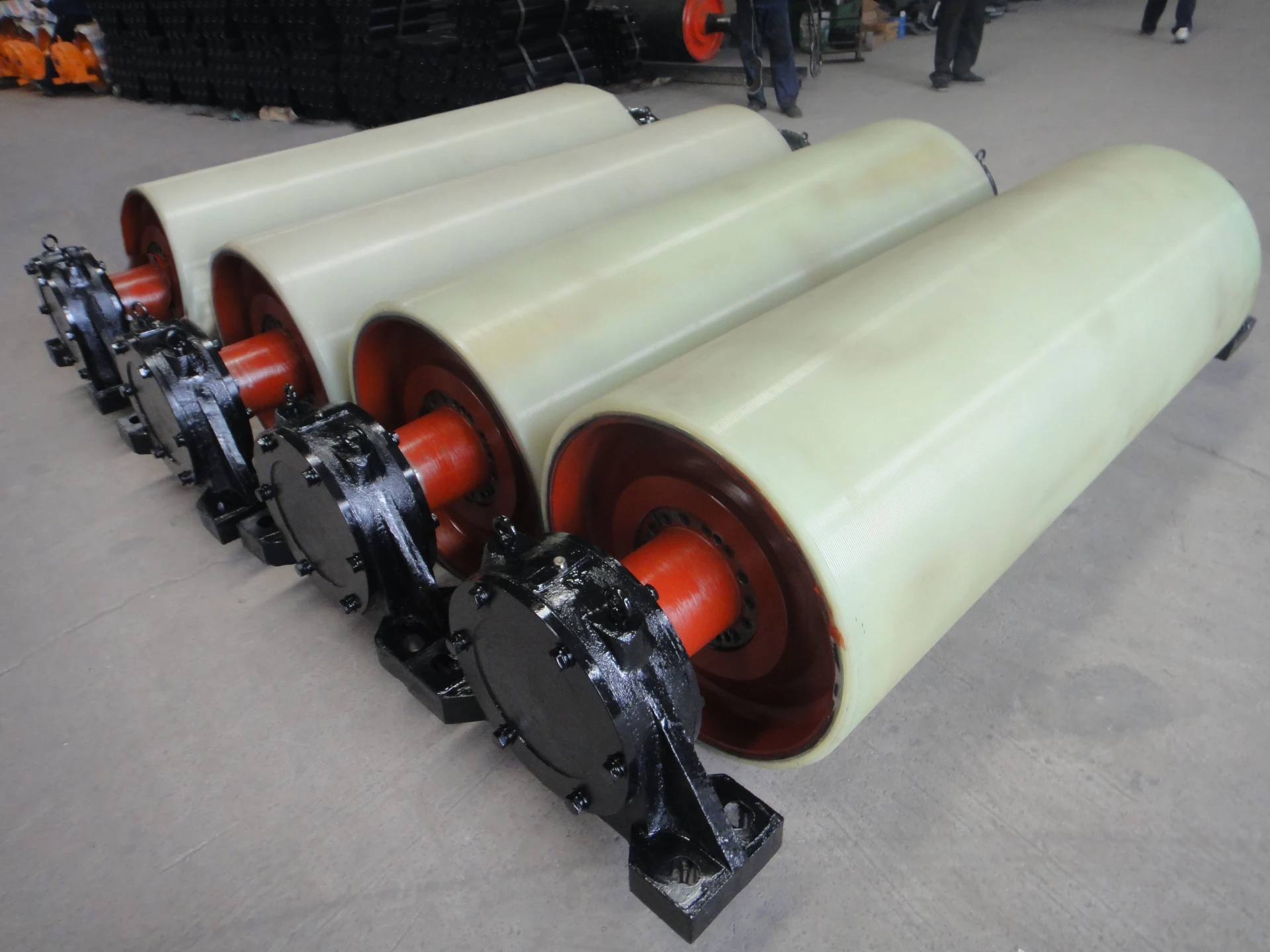

conveyor side guide rollers

Navigating the intricate world of conveyor systems can often feel like stepping into a realm of mechanical complexity and innovation. At the heart of these systems, conveyor side guide rollers play a pivotal role in ensuring efficiency, accuracy, and safety. They are the unsung heroes that smooth the functioning of logistics, manufacturing, and distribution processes worldwide.

Trustworthiness in the context of conveyor side guide rollers is established through stringent quality assurance practices. Reputable manufacturers conduct rigorous testing to ensure their products meet global standards. Certifications such as ISO 9001 for quality management systems are indicators of a reliable product. Consumers should seek out products from manufacturers who provide detailed performance reports and have a documented track record of resolving customer issues efficiently. Practical examples underline the transformative impact of high-quality side guide rollers. In automotive assembly lines, where precision and timing are non-negotiable, rollers that ensure the accurate positioning of components lead to higher assembly accuracy and efficiency. In the e-commerce sector, where conveyor systems facilitate expedited order fulfillment, robust side guide rollers are essential for handling varying package sizes without delays or error. Moreover, sustainable innovations in conveyor side guide rollers are gaining traction, reflecting an industry-wide shift towards eco-friendly practices. Rollers crafted from recycled or biodegradable materials align with corporate social responsibility goals and contribute to reducing the environmental footprint of industrial operations. Companies adopting sustainable solutions not only bolster their brand image but also attract environmentally conscious clientele. In conclusion, conveyor side guide rollers are integral components that determine the efficacy and sustainability of conveyor systems. Leveraging advanced materials, precise engineering, and sustainable practices ensures these rollers not only meet but exceed industry demands. As such, they are indispensable to maintaining competitive edge in industries reliant on efficient material handling. Businesses that invest in top-tier guide rollers position themselves for operational success and technological advancement.

Trustworthiness in the context of conveyor side guide rollers is established through stringent quality assurance practices. Reputable manufacturers conduct rigorous testing to ensure their products meet global standards. Certifications such as ISO 9001 for quality management systems are indicators of a reliable product. Consumers should seek out products from manufacturers who provide detailed performance reports and have a documented track record of resolving customer issues efficiently. Practical examples underline the transformative impact of high-quality side guide rollers. In automotive assembly lines, where precision and timing are non-negotiable, rollers that ensure the accurate positioning of components lead to higher assembly accuracy and efficiency. In the e-commerce sector, where conveyor systems facilitate expedited order fulfillment, robust side guide rollers are essential for handling varying package sizes without delays or error. Moreover, sustainable innovations in conveyor side guide rollers are gaining traction, reflecting an industry-wide shift towards eco-friendly practices. Rollers crafted from recycled or biodegradable materials align with corporate social responsibility goals and contribute to reducing the environmental footprint of industrial operations. Companies adopting sustainable solutions not only bolster their brand image but also attract environmentally conscious clientele. In conclusion, conveyor side guide rollers are integral components that determine the efficacy and sustainability of conveyor systems. Leveraging advanced materials, precise engineering, and sustainable practices ensures these rollers not only meet but exceed industry demands. As such, they are indispensable to maintaining competitive edge in industries reliant on efficient material handling. Businesses that invest in top-tier guide rollers position themselves for operational success and technological advancement.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS