Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 15, 2025 17:54

Back to list

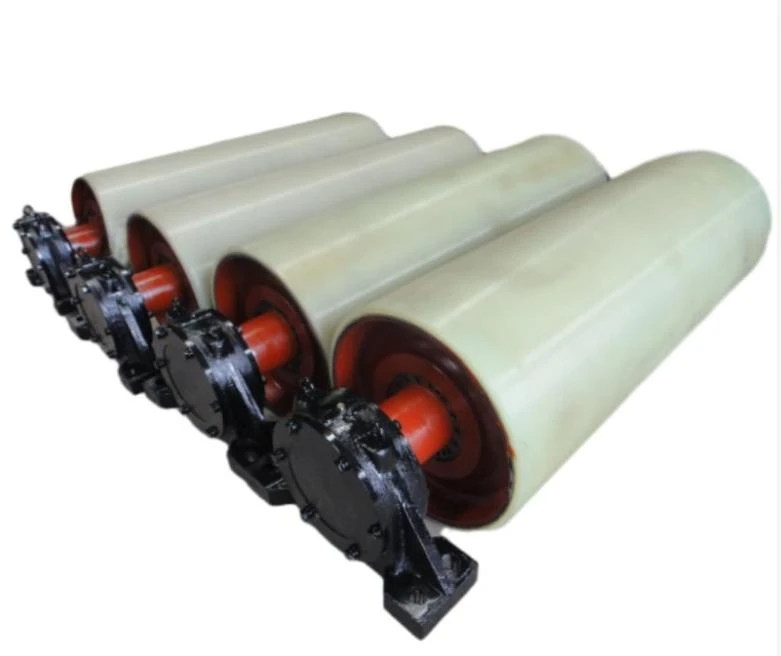

Impact Bed

Navigating the complex world of conveyor systems can often seem daunting, especially when you're in search of the right components to streamline your operational flow. Among these components, the conveyor side guide stands out, a critical aspect that ensures smooth transit of materials across different stages of production or distribution.

From an expertise standpoint, consultation with industry specialists can uncover innovative solutions that blend seamlessly with existing infrastructure, ultimately improving operational throughput. Consulting with professionals also provides insights into emergent technologies, which could revolutionize the role of conveyor side guides in years to come. Authoritative voices in the field often highlight the importance of investing in research and development to drive product advancement. An emphasis on R&D allows manufacturers to explore new materials and designs, potentially banishing historical pitfalls associated with outdated side guide models. Building trust with consumers is facilitated by ensuring transparency regarding the benefits and limitations of different conveyor side guide models. Providing detailed case studies showcasing real-world applications and outcomes can significantly boost consumer confidence. It's not just about showcasing products but building narratives around success stories that demonstrate efficacy and reliability. Finally, to foster a competitive edge, businesses should consider employing environmentally friendly practices in the production of conveyor side guides. As sustainability becomes an undeniable part of the industrial landscape, commitment to eco-friendly practices not only enhances brand image but also appeals to an environmentally conscious consumer base. In conclusion, while often overlooked, conveyor side guides are an indispensable part of conveyor system optimization. By focusing on experience, expertise, authoritativeness, and trustworthiness, companies can significantly enhance their operational efficiencies, maintain competitive positioning, and ensure that their production lines run smoothly. Understanding and leveraging these elements is the essence of harnessing the potential of a well-integrated conveyor side guide system.

From an expertise standpoint, consultation with industry specialists can uncover innovative solutions that blend seamlessly with existing infrastructure, ultimately improving operational throughput. Consulting with professionals also provides insights into emergent technologies, which could revolutionize the role of conveyor side guides in years to come. Authoritative voices in the field often highlight the importance of investing in research and development to drive product advancement. An emphasis on R&D allows manufacturers to explore new materials and designs, potentially banishing historical pitfalls associated with outdated side guide models. Building trust with consumers is facilitated by ensuring transparency regarding the benefits and limitations of different conveyor side guide models. Providing detailed case studies showcasing real-world applications and outcomes can significantly boost consumer confidence. It's not just about showcasing products but building narratives around success stories that demonstrate efficacy and reliability. Finally, to foster a competitive edge, businesses should consider employing environmentally friendly practices in the production of conveyor side guides. As sustainability becomes an undeniable part of the industrial landscape, commitment to eco-friendly practices not only enhances brand image but also appeals to an environmentally conscious consumer base. In conclusion, while often overlooked, conveyor side guides are an indispensable part of conveyor system optimization. By focusing on experience, expertise, authoritativeness, and trustworthiness, companies can significantly enhance their operational efficiencies, maintain competitive positioning, and ensure that their production lines run smoothly. Understanding and leveraging these elements is the essence of harnessing the potential of a well-integrated conveyor side guide system.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS