Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 30, 2025 01:50

Back to list

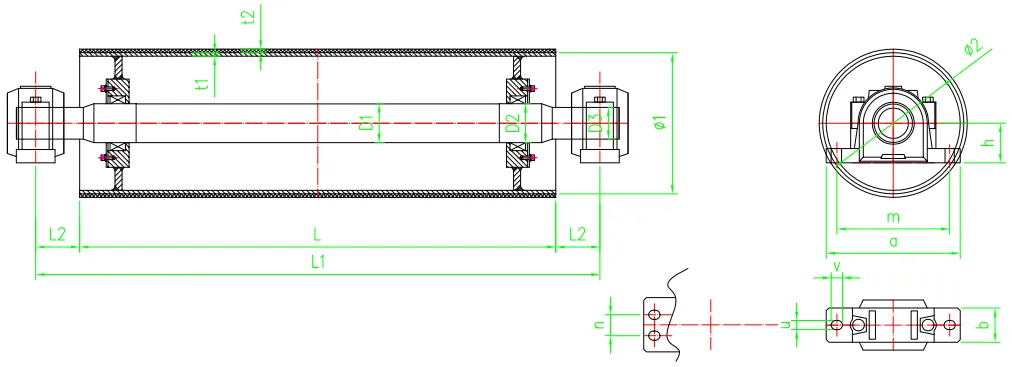

conveyor side bracket

The ever-evolving world of industrial automation has driven manufacturers and engineers to seek innovative methods for enhancing production processes. Central to this continuous growth is the conveyor system, a staple in various industries from automotive to food processing. Among the critical components of these systems is the conveyor side bracket—a seemingly simple yet indispensable part that ensures the smooth and efficient operation of conveyors.

Proper installation and maintenance of conveyor side brackets are imperative to maximize efficiency and lifespan. During installation, it's crucial to ensure that the side brackets are precisely aligned with the belt and securely fastened. Misalignment can lead to uneven belt tension and increased wear, reducing the operational efficiency and potentially leading to system failures. Routine checks and maintenance are equally important; regular inspections for wear, misalignment, and structural damage can prevent costly downtime and extend the service life of the brackets. A discussion on conveyor side brackets would be incomplete without addressing the growing trend towards smart technology integration. The advent of the Industrial Internet of Things (IIoT) has empowered manufacturers with sensors and automation solutions that provide real-time data on the conveyor operations. Integrating sensors with conveyor side brackets allows for continuous monitoring of their condition and performance. Early detection of potential issues such as unusual vibrations or other anomalies can prompt preemptive maintenance actions, avoiding unexpected breakdowns. Furthermore, the authority of a manufacturer or supplier in the conveyor industry is often measured by their ability to adapt to trends and offer customizable solutions that meet specific industry needs. Innovative companies are now offering modular conveyor side bracket systems that cater to bespoke requirements, showcasing their expertise and commitment to delivering tailored solutions. Trust remains a cornerstone of the relationship between component manufacturers and their customers. A transparent approach to communicating the capabilities and limitations of conveyor side brackets builds trust. Detailed documentation, comprehensive testing results, and customer testimonials are all valuable tools in fostering confidence amongst clientele, ensuring that purchasers are making informed and satisfactory decisions. In conclusion, conveyor side brackets, while a fractional part of the broader conveyor system, play an integral role in ensuring smooth, efficient, and reliable operations. A thoughtful approach to material selection, design expertise in load handling, adaptability features, and even technology integration are essential considerations that can significantly enhance the performance of conveyor systems. By acknowledging these aspects, manufacturers can position themselves as trustworthy and authoritative industry leaders, paving the way for robust, future-ready conveyance solutions.

Proper installation and maintenance of conveyor side brackets are imperative to maximize efficiency and lifespan. During installation, it's crucial to ensure that the side brackets are precisely aligned with the belt and securely fastened. Misalignment can lead to uneven belt tension and increased wear, reducing the operational efficiency and potentially leading to system failures. Routine checks and maintenance are equally important; regular inspections for wear, misalignment, and structural damage can prevent costly downtime and extend the service life of the brackets. A discussion on conveyor side brackets would be incomplete without addressing the growing trend towards smart technology integration. The advent of the Industrial Internet of Things (IIoT) has empowered manufacturers with sensors and automation solutions that provide real-time data on the conveyor operations. Integrating sensors with conveyor side brackets allows for continuous monitoring of their condition and performance. Early detection of potential issues such as unusual vibrations or other anomalies can prompt preemptive maintenance actions, avoiding unexpected breakdowns. Furthermore, the authority of a manufacturer or supplier in the conveyor industry is often measured by their ability to adapt to trends and offer customizable solutions that meet specific industry needs. Innovative companies are now offering modular conveyor side bracket systems that cater to bespoke requirements, showcasing their expertise and commitment to delivering tailored solutions. Trust remains a cornerstone of the relationship between component manufacturers and their customers. A transparent approach to communicating the capabilities and limitations of conveyor side brackets builds trust. Detailed documentation, comprehensive testing results, and customer testimonials are all valuable tools in fostering confidence amongst clientele, ensuring that purchasers are making informed and satisfactory decisions. In conclusion, conveyor side brackets, while a fractional part of the broader conveyor system, play an integral role in ensuring smooth, efficient, and reliable operations. A thoughtful approach to material selection, design expertise in load handling, adaptability features, and even technology integration are essential considerations that can significantly enhance the performance of conveyor systems. By acknowledging these aspects, manufacturers can position themselves as trustworthy and authoritative industry leaders, paving the way for robust, future-ready conveyance solutions.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS