Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

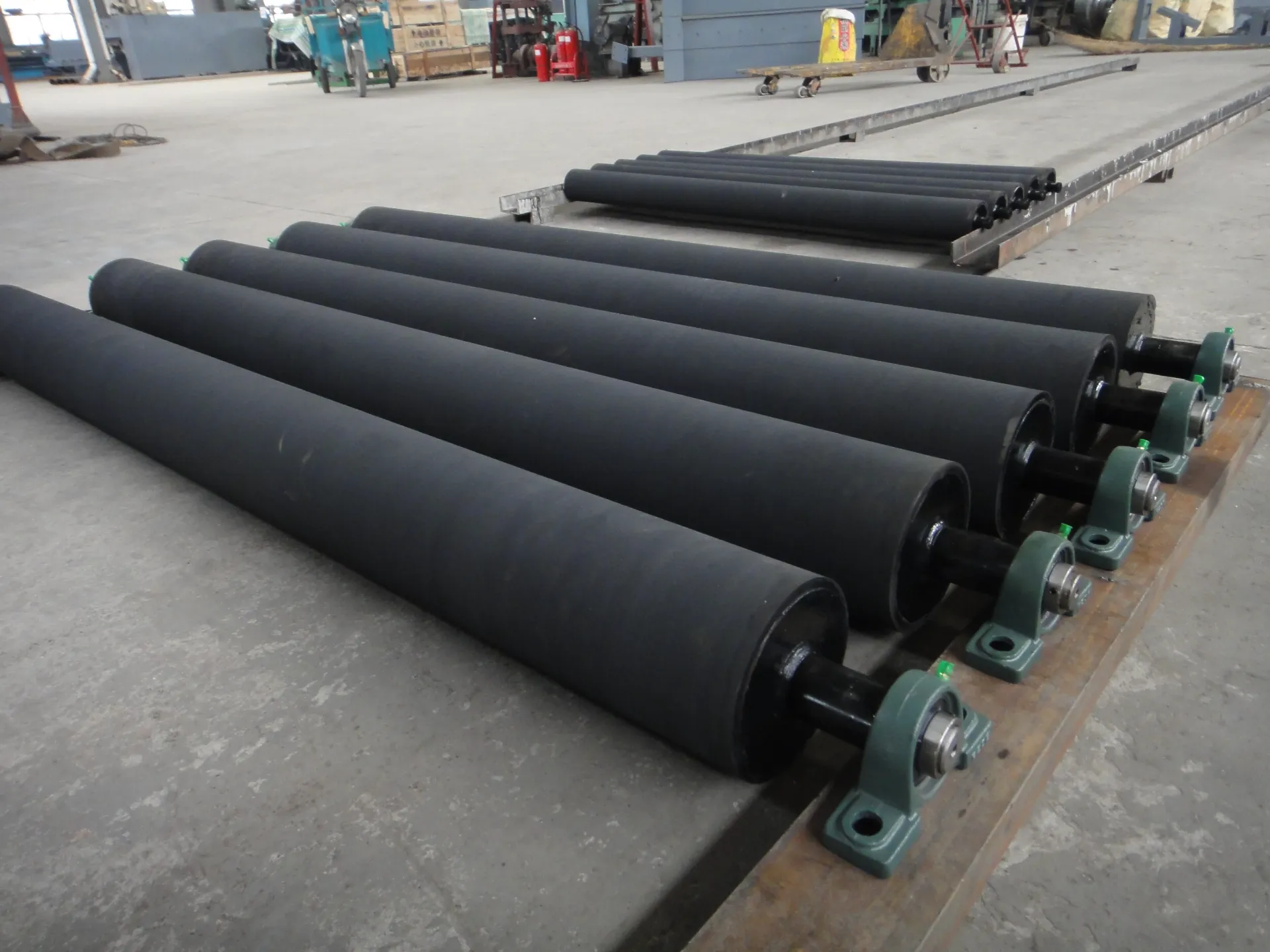

Zulu conveyor roller stands

Conveyor Roller Stands Enhancing Efficiency in Material Handling

In today's fast-paced industrial landscape, the need for efficient and reliable material handling systems is paramount. Conveyor roller stands have emerged as an essential component in optimizing workflow and enhancing productivity across various sectors, from manufacturing and warehousing to distribution centers and retail operations. This article explores the significance of conveyor roller stands and their role in modern material handling solutions.

What are Conveyor Roller Stands?

Conveyor roller stands are support structures designed to hold and guide conveyor rollers, which facilitate the movement of materials or goods along a conveyor system. These stands can be adjustable or fixed, allowing for versatile configurations to accommodate different types of products and operational needs. They are used to create gravity-fed conveyor systems, where items glide down the conveyor using gravity, as well as in powered conveyor systems that rely on motors to move the rollers.

Importance of Conveyor Roller Stands

1. Improved Efficiency One of the primary advantages of conveyor roller stands is the significant improvement in operational efficiency they offer. By enabling smooth movement of items across various heights and distances, these stands eliminate the need for manual handling, reducing time and labor costs associated with transporting goods.

2. Space Optimization In warehouses and production facilities, space is often at a premium. Conveyor roller stands allow for the effective use of vertical space, as conveyors can be set at different heights. This vertical integration means that more items can be stored or processed in a smaller footprint, making it easier to manage inventory and increase throughput.

conveyor roller stands

3. Versatility Conveyor roller stands come in various designs and configurations to meet the unique needs of different industries. They can be customized for handling diverse materials, from heavy pallets to lightweight boxes. The ability to adapt the roller stands for various applications makes them a valuable asset to any material handling system.

4. Durability and Longevity Constructed from robust materials, conveyor roller stands are built to withstand the rigors of daily operation. Whether in high-stress environments or under heavy loads, these stands maintain their integrity and performance over time, reducing the need for frequent replacements and minimizing downtime.

5. Safety Enhancements Safety is a crucial consideration in any industrial setting. Conveyor roller stands are designed with features that enhance safety for operators and workers. Smooth rollers reduce the risk of product damage and personnel injury, while proper alignment and secure supports prevent falls and accidents.

Applications of Conveyor Roller Stands

Conveyor roller stands are widely utilized in various sectors. In manufacturing, they facilitate the movement of raw materials and finished products along assembly lines. In warehouses, they streamline the picking and packing processes, enabling employees to efficiently sort and distribute items. Additionally, in retail environments, conveyor roller stands are often used in checkout systems to improve customer service by expediting the checkout process.

Conclusion

As industries continue to evolve, the importance of efficient material handling systems cannot be overstated. Conveyor roller stands play a vital role in supporting these systems, enhancing operational efficiency, and contributing to safety within the workplace. By investing in high-quality conveyor roller stands, businesses can not only improve productivity but also ensure a safer and more organized work environment. For companies looking to enhance their material handling processes, integrating conveyor roller stands into their operations is a step toward achieving greater efficiency and success in today's competitive market.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025