Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Suppliers of Conveyor Rollers for Efficient Material Handling Solutions

Understanding Conveyor Rollers A Guide to Suppliers and Their Offerings

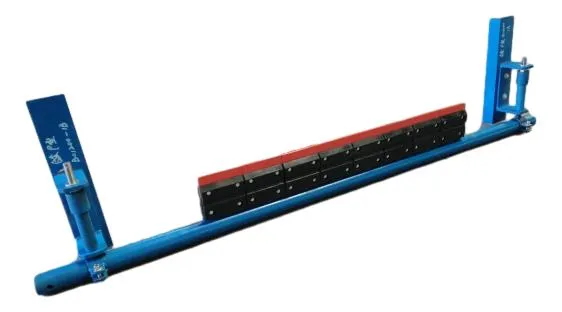

Conveyor systems are pivotal in numerous industrial settings, streamlining the movement of goods and materials. A critical component of these systems is the conveyor roller, which is responsible for providing support and facilitating the movement of materials along the belt. In this article, we will explore the significance of conveyor rollers, various types available, and how to choose reliable suppliers.

The Importance of Conveyor Rollers

Conveyor rollers are essential in maintaining the efficiency and productivity of conveyor systems. They reduce friction and wear on the conveyor belt, allowing for smoother transportation of goods. This efficiency not only minimizes operating costs but also enhances the lifespan of the conveyor system overall. Different types of rollers cater to specific applications, such as transporting heavy loads, handling fragile materials, or working in extreme temperatures.

Types of Conveyor Rollers

1. Straight Rollers These are the most common type of conveyor rollers, used for standard applications. They can be made from various materials, including steel, plastic, and aluminum.

2. Idler Rollers These rollers are designed to support the conveyor belt and allow it to glide smoothly. They play a vital role in preventing excessive wear on the belt and are crucial for maintaining the alignment of materials during transportation.

3. Return Rollers Used on the underside of a conveyor, return rollers ensure that the belt remains in position while it returns to the loading station. They help in keeping the conveyor belt taut and reduce sagging.

4. Guard Rollers These are used to guide the transport of materials, preventing them from falling off the belt. Guard rollers are especially important in applications with inclines or declines.

5. Specialty Rollers For specific applications, such as high-temperature or corrosive environments, specialty rollers made from specific materials or with unique designs are necessary. These might include rollers designed for food-grade applications, where hygiene is crucial.

conveyor rollers suppliers

Choosing Reliable Suppliers

When it comes to sourcing conveyor rollers, choosing a dependable supplier is paramount. Here are some key factors to consider

1. Quality and Standards The longevity and functionality of conveyor rollers depend on the quality of materials and manufacturing processes used. Ensure that suppliers adhere to industry standards and possess relevant certifications. This not only guarantees reliability but also enhances safety in your operations.

2. Customization Different applications require different specifications. A good supplier should offer customization options to meet your specific needs, whether it's altering the size, material, or design of the rollers.

3. Service and Support Post-sale service is just as crucial as the product itself. Choose suppliers that provide excellent customer support, including installation guidance and maintenance advice. Their expertise can be invaluable in optimizing your conveyor system’s performance.

4. Reputation and Reliability Research potential suppliers by reading reviews, checking testimonials, and comparing their offerings. A supplier with a strong reputation in the industry often signals good reliability and quality.

5. Turnaround Time In many cases, downtime can be costly. Assess the supplier’s lead time for delivery and their willingness to expedite orders when necessary. Suppliers that can quickly react to your needs can help minimize disruption in your operations.

6. Price While cost is an important factor, it should not be the sole determinant. Evaluate the value that each supplier provides in relation to their pricing. Often, a slightly higher investment in quality products can lead to overall savings in maintenance and operational costs.

Conclusion

Conveyor rollers are essential components that significantly affect the efficiency of conveyor systems. Understanding the various types of rollers and selecting reliable suppliers are crucial steps in enhancing your operations. By prioritizing quality, customization, service, and reputation when choosing suppliers, you can ensure that your conveyor system runs smoothly and efficiently, ultimately contributing to the overall success of your business. Take the time to research and establish a relationship with reputable suppliers who can meet your needs now and in the future.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025