Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor roller parts

Understanding Conveyor Roller Parts Essential Components for Efficient Transport Systems

Conveyor systems are the backbone of many industrial operations, providing a reliable means to transport materials across various processes. A pivotal component of these systems is the conveyor roller, which plays a crucial role in ensuring smooth and efficient movement of goods. Understanding the parts of conveyor rollers not only enhances operational efficiency but also aids in maintenance and troubleshooting.

1. Introduction to Conveyor Rollers

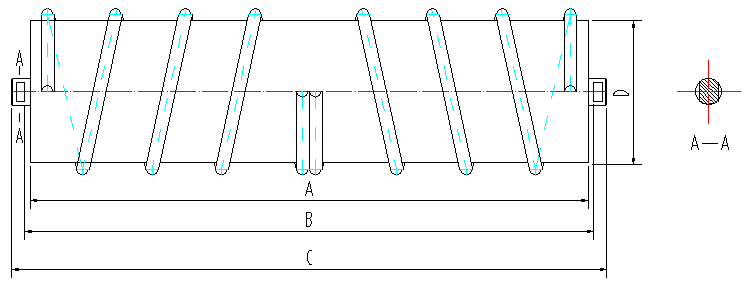

Conveyor rollers are cylindrical components that form the basis of many conveyor systems. They are responsible for supporting the conveyor belt and facilitating the movement of materials along the conveyor line. With various designs and specifications available, conveyor rollers can be tailored to meet the demands of specific applications, including heavy-duty transport, lightweight handling, and everything in between.

2. Key Components of Conveyor Rollers

At the core of every conveyor roller lies several essential parts that ensure its functionality and durability

- Steel Tube The main body of the roller is typically made from robust steel or aluminum tubing. This component provides the necessary strength to bear heavy loads while maintaining structural integrity. The thickness of the tube can vary depending on the application, ensuring adequate support for the conveyed materials.

- End Caps These are fitted at either end of the roller and serve multiple purposes. Primarily, they protect the internal components from dust and debris while also ensuring that the rollers do not deform under pressure. End caps can be made from various materials, including plastic or metal, depending on the roller's intended use.

conveyor roller parts

- Bearing Bearings are critical to the functionality of conveyor rollers. They allow the roller to rotate smoothly, minimizing friction and wear on both the roller and the conveyor belt. There are different types of bearings, including sealed bearings, that require little to no maintenance, and open bearings, which may need regular lubrication for optimal performance.

- Shaft The shaft connects the roller to the conveyor frame and allows it to rotate. It is typically made from high-strength steel to withstand heavy loads and impacts. Proper shaft design is crucial, as it affects the overall stability and efficiency of the conveyor system.

- Spacer Often used to maintain the correct distance between rollers, spacers help in aligning the conveyor system accurately and ensuring smooth operation. They can be particularly useful in multi-roller configurations where proper spacing is vital for efficiency.

3. Types of Conveyor Rollers

Conveyor rollers come in various types, each designed for specific applications. Heavy-duty rollers are designed for transporting bulk materials in mining and construction, while light-duty rollers are used in package handling and warehouse settings. There are also specialty rollers, such as those fitted with rubber sleeves for handling delicate items.

4. Conclusion

The importance of conveyor roller parts cannot be overstated. Each component plays a vital role in the overall performance and longevity of conveyor systems. By understanding the intricacies of these parts, businesses can enhance their material handling processes, reduce maintenance costs, and improve operational efficiency. As industries continue to evolve, the demand for efficient conveyor systems and high-quality roller parts will only grow, making it essential for manufacturers to stay ahead of technological advancements. Investing in superior conveyor roller components is a critical step towards achieving optimal productivity and reliability in any industrial operation.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025