Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor roller parts

Understanding Conveyor Roller Parts Essential Components for Efficient Operations

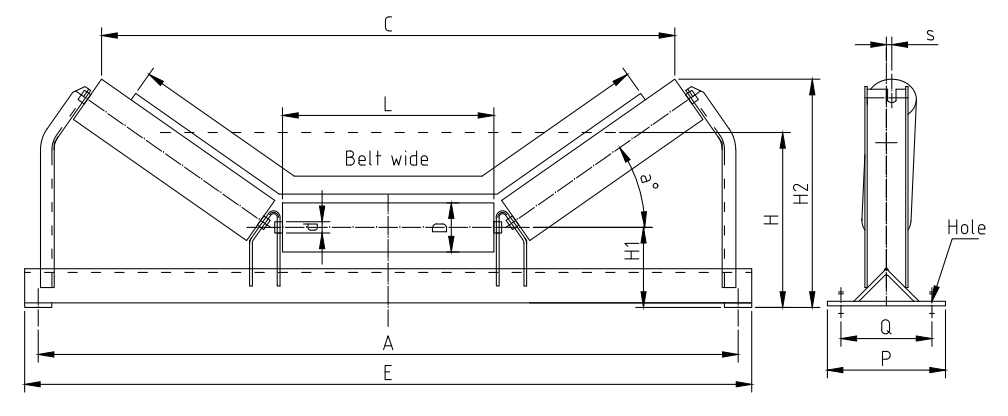

Conveyor rollers play a critical role in the logistics and manufacturing industries, facilitating the smooth movement of goods and materials across various environments. These essential components are designed to support the weight of the loads being transported, reduce friction, and enhance overall operational efficiency. Understanding the various parts of conveyor rollers is crucial for anyone involved in maintaining or operating conveyor systems.

1. Roller Shell The Outer Layer

The roller shell, often made from materials such as steel, plastic, or aluminum, serves as the outer layer of the roller. It is the primary component that carries the load and protects the internal mechanisms. The thickness and material of the shell depend on the application and the weight of the items being transported. A robust shell is essential for heavy-duty use, whereas lighter materials might suffice for delicate items.

2. Bearings Smooth Operation

Located at both ends of the roller, the bearings are pivotal to the smooth rotation of the roller. They reduce friction between the roller and the axle, facilitating efficient movement. There are various types of bearings, including standard ball bearings, sealed bearings, and self-lubricating options. Choosing the right bearing type is essential for minimizing wear and ensuring longevity in high-speed applications or environments with dirt and debris.

3. Axles The Support Structure

The axle acts as the central shaft for the roller, providing the necessary support and structure. Typically made from heavy-duty steel, the axle must withstand substantial forces and impacts. It is essential that the axle is compatible with the bearing type, as the roller’s performance largely depends on how well these two parts work together. Proper installation and alignment of the axle are crucial for minimizing vibrations and enhancing operational efficiency.

conveyor roller parts

4. End Caps Protection and Stability

End caps are crucial for keeping the internal components secure and protected from environmental factors. These caps, usually made from plastic or rubber, not only secure the bearings in place but also prevent dust and debris from infiltrating the roller’s internal mechanisms. Additionally, they prevent the roller from coming loose, which could lead to system breakdowns or accidents.

5. Spindles Connecting Components

The spindle is another critical component of the conveyor roller. It connects the roller to the conveyor frame, allowing the roller to function as part of the larger conveyor system. The design and material of the spindle can vary, but they must be strong enough to support the entire weight of the roller and the transported materials. Choosing the right spindle contributes to efficient loading and unloading processes.

6. Maintenance Considerations

Regular maintenance of conveyor roller parts is vital to ensure optimal performance. This includes checking for wear and tear on the bearings, monitoring the condition of the roller shell, and ensuring the proper alignment of the axle and spindle. Implementing a routine maintenance schedule not only prolongs the life of the rollers but also enhances overall system reliability.

Conclusion

Understanding the different parts of conveyor rollers is essential for effective operations in various industries. By recognizing the function and importance of each component, businesses can ensure their conveyor systems operate smoothly and efficiently, thus maximizing productivity and minimizing downtime. Investing in quality parts and regular maintenance is key to achieving long-term success in material handling operations.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025