Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 16, 2025 01:15

Back to list

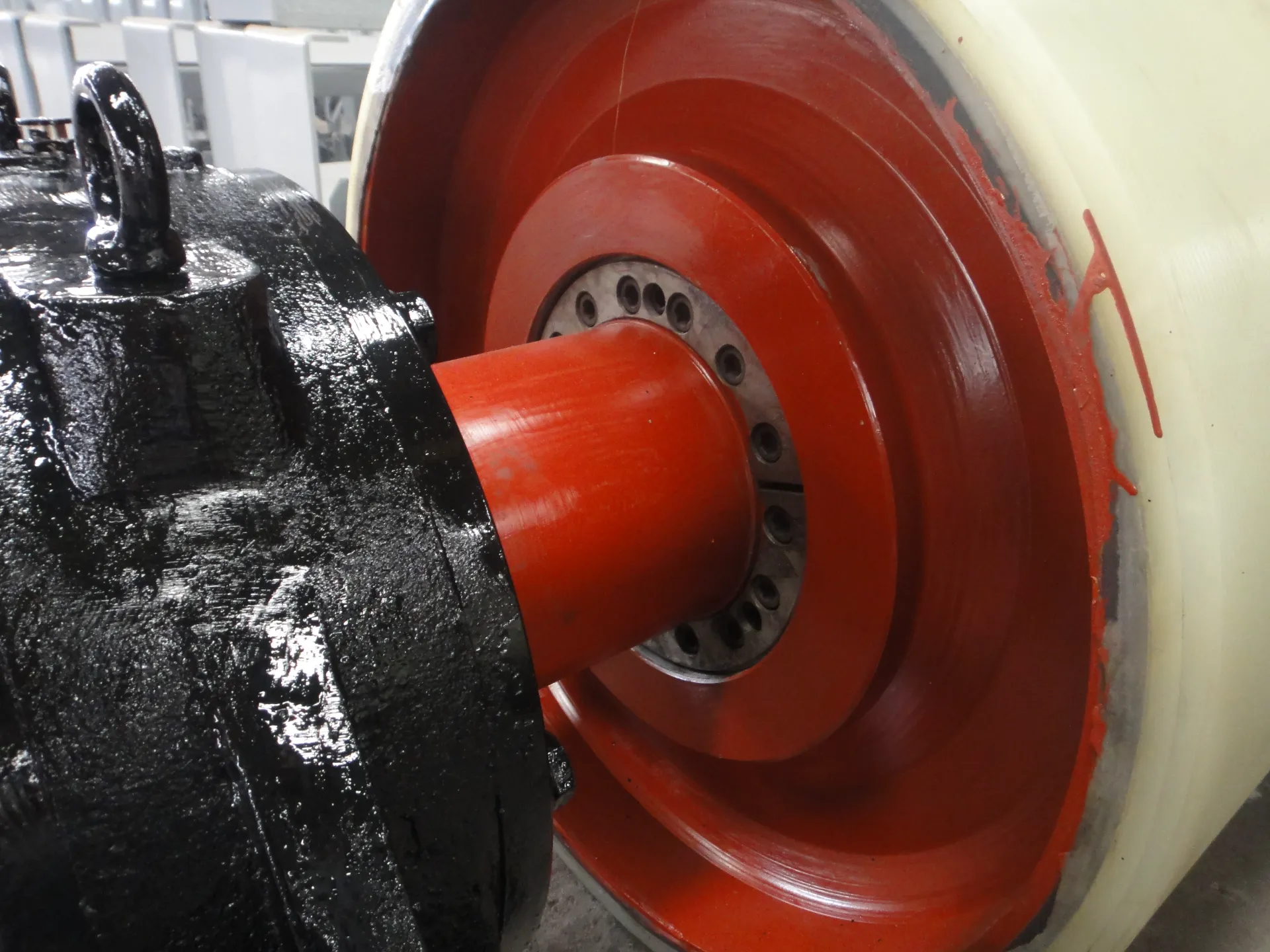

Belt Conveyor Cleaner

Conveyor roller cleaners might not be the most glamorous component of an industrial setup, but their efficiency can make a substantial difference in operations. At the heart of every effective conveyor system lies the proper handling of materials—keeping the belt free of debris is crucial. A reliable conveyor roller cleaner is the unsung hero in these settings, helping industries maintain productivity and minimize downtime. Its impact extends beyond mere cleanliness, directly affecting a company's bottom line and operational efficiency.

In addition to operational efficiency, there's a broader ecological and safety narrative. Cleaner conveyor systems mean less material spillage, which not only reduces waste but also minimizes environmental harm. Excessive debris on conveyors can be a potential safety hazard, creating slip risks or becoming fire hazards in some environments. Here, conveyor roller cleaners contribute significantly to both ecological responsibility and workplace safety. The economic argument for investing in conveyor roller cleaners is equally compelling. The initial investment is quickly offset by the decreased operational disruptions, reduced maintenance costs, and the extended lifespan of the conveyor system itself. Over time, the cost savings realized from avoiding regular belt replacements and minimizing system downtimes can be substantial. Authoritative voices in the industry continuously stress the importance of choosing the right partner when selecting conveyor roller cleaners. With numerous options on the market, discerning quality and reliability is crucial. Companies should look for vendors with a proven track record, testimonials, and case studies that highlight successful implementations. Customer reviews often underline aspects such as product longevity, ease of installation, and consistent performance as critical decision points. Building trust in these products is key, and real-world endorsements play a pivotal role. Field tests and pilot programs provide tangible proof of performance, often highlighting how these cleaners handle specific challenges intrinsic to different industries—from mining to agriculture to manufacturing. This evidential backing lends substantial credibility to quality roller cleaners. Conveyor roller cleaners might work silently in the backdrop, but their benefits resonate across multiple facets of an industry. By offering unmatched reliability and efficiency, they prove indispensable in maintaining the standard of operations expected in today's competitive environments. Whether a business focuses on scale or precision, incorporating a quality conveyor roller cleaner ensures that operational excellence is continually achieved and maintained.

In addition to operational efficiency, there's a broader ecological and safety narrative. Cleaner conveyor systems mean less material spillage, which not only reduces waste but also minimizes environmental harm. Excessive debris on conveyors can be a potential safety hazard, creating slip risks or becoming fire hazards in some environments. Here, conveyor roller cleaners contribute significantly to both ecological responsibility and workplace safety. The economic argument for investing in conveyor roller cleaners is equally compelling. The initial investment is quickly offset by the decreased operational disruptions, reduced maintenance costs, and the extended lifespan of the conveyor system itself. Over time, the cost savings realized from avoiding regular belt replacements and minimizing system downtimes can be substantial. Authoritative voices in the industry continuously stress the importance of choosing the right partner when selecting conveyor roller cleaners. With numerous options on the market, discerning quality and reliability is crucial. Companies should look for vendors with a proven track record, testimonials, and case studies that highlight successful implementations. Customer reviews often underline aspects such as product longevity, ease of installation, and consistent performance as critical decision points. Building trust in these products is key, and real-world endorsements play a pivotal role. Field tests and pilot programs provide tangible proof of performance, often highlighting how these cleaners handle specific challenges intrinsic to different industries—from mining to agriculture to manufacturing. This evidential backing lends substantial credibility to quality roller cleaners. Conveyor roller cleaners might work silently in the backdrop, but their benefits resonate across multiple facets of an industry. By offering unmatched reliability and efficiency, they prove indispensable in maintaining the standard of operations expected in today's competitive environments. Whether a business focuses on scale or precision, incorporating a quality conveyor roller cleaner ensures that operational excellence is continually achieved and maintained.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS