Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

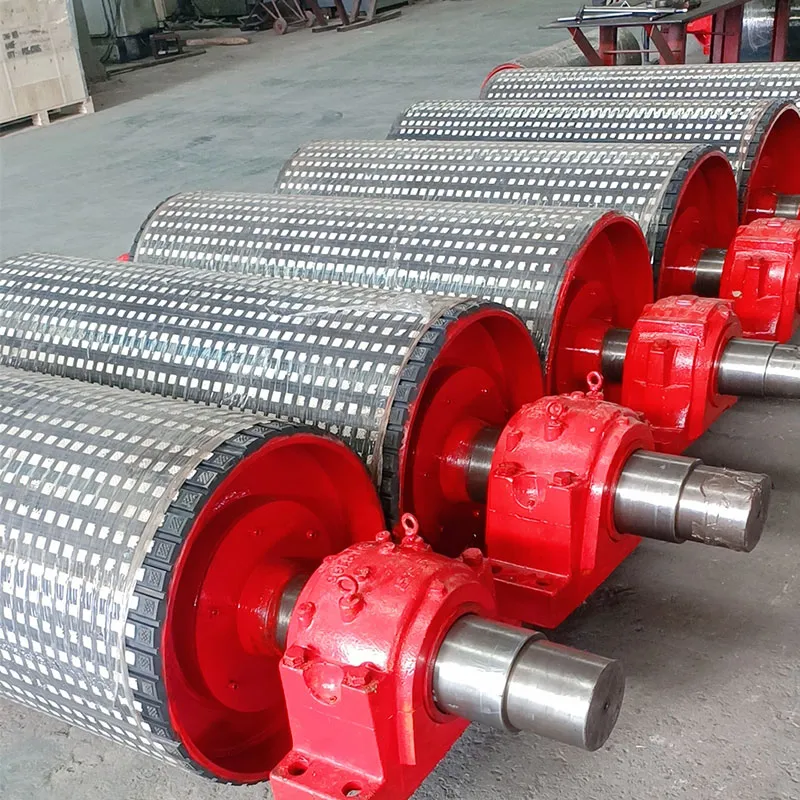

Zulu Conveyor Belt Roller Maintenance and Cleaning Solutions for Optimal Performance

The Importance of Conveyor Roller Cleaners in Industrial Operations

Conveyor systems are the backbone of many industrial processes, facilitating the swift and efficient movement of goods and materials. However, with continuous operation comes the accumulation of debris, dust, and contaminants that can affect performance, safety, and product quality. This is where conveyor roller cleaners come into play, providing a critical support role in maintaining the longevity and functionality of conveyor systems.

Conveyor roller cleaners are specialized devices designed to remove foreign material from the rollers and belts of conveyor systems. These cleaners come in various designs, employing brushes, scrapers, or wiping mechanisms to ensure that the surfaces remain clean and free from obstruction. The effectiveness of these devices can significantly influence the efficiency of conveyor operations and ultimately impact the overall productivity of the facility.

One of the primary benefits of using a conveyor roller cleaner is the reduction of friction. Contaminants such as dust, grease, and debris can increase friction on the rollers, leading to excessive wear and tear. By keeping the rollers clean, these devices help maintain optimal operating conditions, reducing the likelihood of breakdowns and the need for expensive repairs. This proactive maintenance approach not only saves money but also minimizes downtime, allowing for a more streamlined production process.

conveyor roller cleaner

Moreover, conveyor roller cleaners play an essential role in ensuring product quality. In industries such as food processing and pharmaceuticals, cleanliness is paramount. Contaminants on conveyor surfaces can lead to product contamination, which can have dire consequences, including recalls and damage to a company’s reputation. Implementing effective cleaning systems ensures that products are transported in a hygienic environment, meeting safety standards and preserving the integrity of the products.

Additionally, the use of roller cleaners contributes to workplace safety. A buildup of debris can result in slip hazards for employees working near conveyor systems. By keeping the rollers clean, the risk of accidents can be significantly reduced, creating a safer working environment. Safety should always be a top priority in any industrial setup, and employing conveyor roller cleaners is one of the simplest yet most effective methods to achieve this goal.

Furthermore, integrating conveyor roller cleaners into regular maintenance routines is an environmentally friendly practice. Reducing wear on the rollers means less energy consumption and lower emissions associated with operating machinery. In an age where sustainability is becoming increasingly important, such practices align with corporate responsibility initiatives and contribute to a greener operational footprint.

In conclusion, conveyor roller cleaners are an indispensable aspect of modern industrial operations. They enhance efficiency, ensure product quality, promote workplace safety, and support environmental sustainability. By investing in these essential cleaning devices, companies can maintain their conveyor systems in top working condition, thereby optimizing their production capabilities and safeguarding their reputation in an ever-competitive market. As industries continue to evolve, the importance of effective cleaning solutions will only grow, making conveyor roller cleaners a vital component of operational success.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025