Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 26, 2025 06:11

Back to list

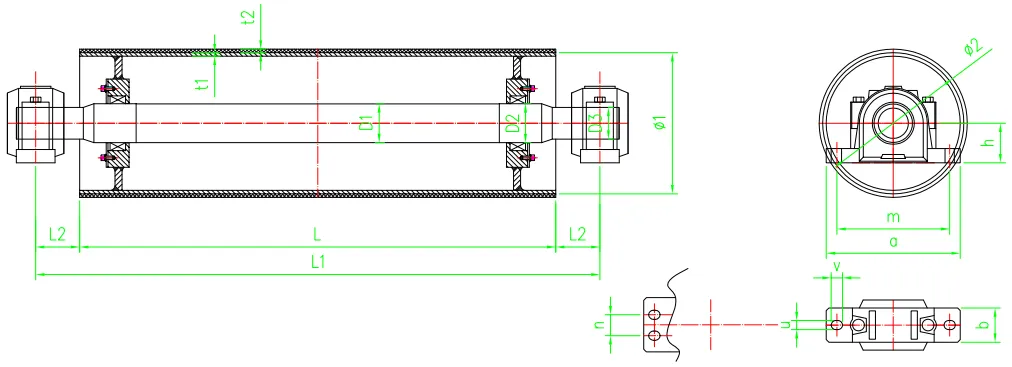

idler roller assembly

In the realm of industrial manufacturing and logistics, conveyor roller assemblies play a pivotal role in streamlining operations and enhancing productivity. A detailed understanding of conveyor roller assemblies ensures that businesses maximize their investment and achieve operational excellence. This article sheds light on the essential aspects of conveyor roller assemblies, imbued with insights from industry experts and real-world applications, ensuring your enterprise reaps substantial benefits.

Authoritativeness in the field of conveyor technology is demonstrated through the integration of advanced technologies such as predictive maintenance tools. These tools utilize sensors and connectivity to monitor roller assembly performance in real-time, alerting technicians to potential issues before they escalate into costly failures. Leveraging data analytics for maintenance scheduling not only extends equipment life but also ensures uninterrupted productivity. Trustworthiness in selecting conveyor roller assemblies is built on the reputation and track record of manufacturers. Leading industry providers offer warranties and certifications that guarantee product integrity and performance standards. Partnering with reputable suppliers who adhere to industry standards such as ISO and offer aftermarket support ensures that your conveyor systems remain at the cutting edge of efficiency. From the experiences of industry veterans, one real-world success story highlights a logistics company that revamped its operations by upgrading to conveyor roller assemblies with dynamic load capacities and shock absorption capabilities. The transformation led to a 30% increase in throughput efficiency and a 15% reduction in energy costs, illustrating how strategic enhancements in conveyor technology can drive significant business performance improvements. In conclusion, the investment in high-quality conveyor roller assemblies is not merely about immediate operational gains but a long-term strategic initiative that enhances your supply chain's overall productivity and sustainability. Expertise, coupled with advanced technological integrations, ensures that your conveyor systems remain reliable, efficient, and adaptable, meeting the ever-evolving demands of modern industrial operations. By selecting the right roller assemblies and partnering with authoritative industry leaders, businesses can establish robust logistical processes that reinforce their competitive edge in a swiftly changing marketplace.

Authoritativeness in the field of conveyor technology is demonstrated through the integration of advanced technologies such as predictive maintenance tools. These tools utilize sensors and connectivity to monitor roller assembly performance in real-time, alerting technicians to potential issues before they escalate into costly failures. Leveraging data analytics for maintenance scheduling not only extends equipment life but also ensures uninterrupted productivity. Trustworthiness in selecting conveyor roller assemblies is built on the reputation and track record of manufacturers. Leading industry providers offer warranties and certifications that guarantee product integrity and performance standards. Partnering with reputable suppliers who adhere to industry standards such as ISO and offer aftermarket support ensures that your conveyor systems remain at the cutting edge of efficiency. From the experiences of industry veterans, one real-world success story highlights a logistics company that revamped its operations by upgrading to conveyor roller assemblies with dynamic load capacities and shock absorption capabilities. The transformation led to a 30% increase in throughput efficiency and a 15% reduction in energy costs, illustrating how strategic enhancements in conveyor technology can drive significant business performance improvements. In conclusion, the investment in high-quality conveyor roller assemblies is not merely about immediate operational gains but a long-term strategic initiative that enhances your supply chain's overall productivity and sustainability. Expertise, coupled with advanced technological integrations, ensures that your conveyor systems remain reliable, efficient, and adaptable, meeting the ever-evolving demands of modern industrial operations. By selecting the right roller assemblies and partnering with authoritative industry leaders, businesses can establish robust logistical processes that reinforce their competitive edge in a swiftly changing marketplace.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS