Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 08, 2025 05:06

Back to list

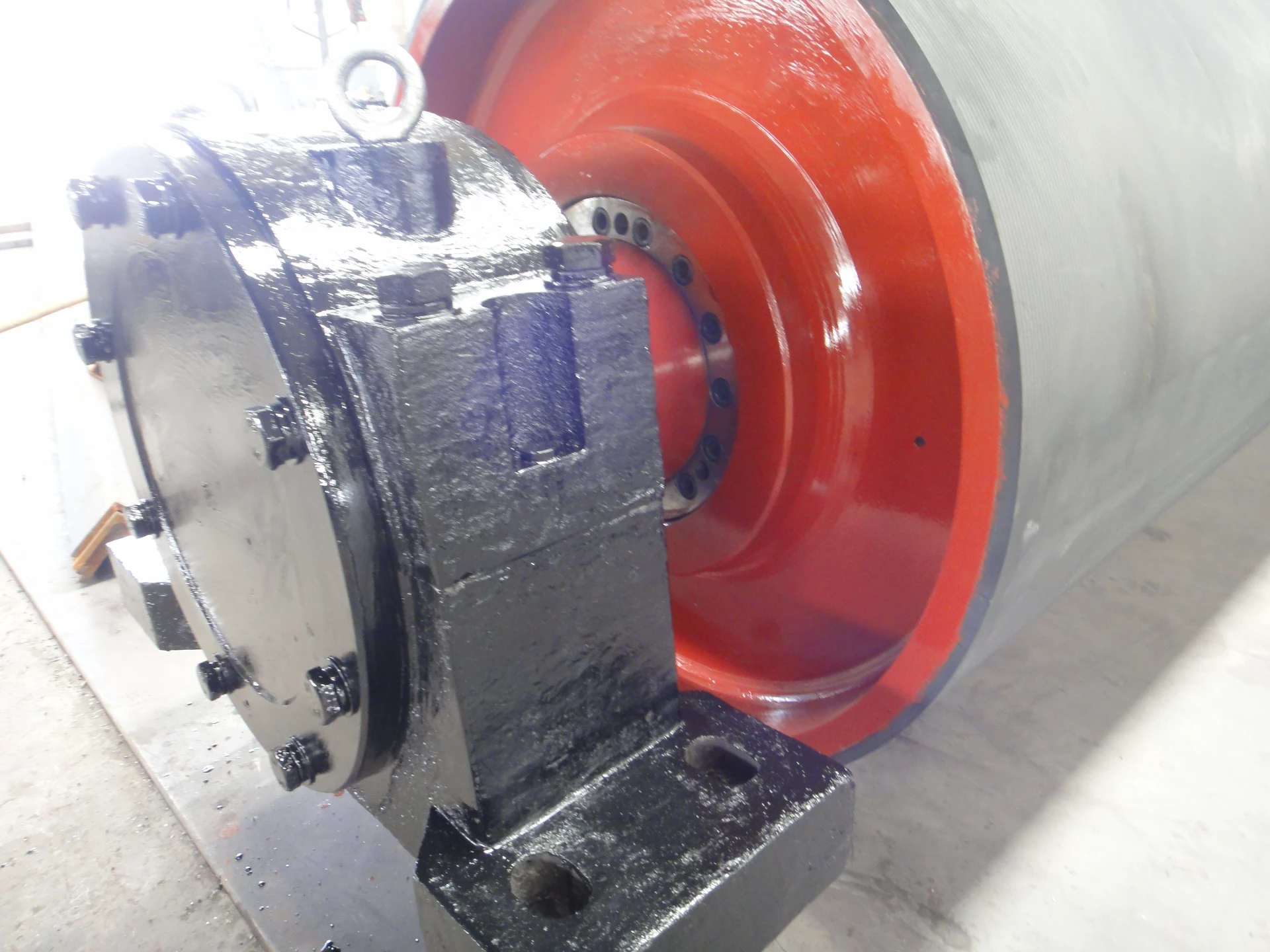

conveyor belt pulley types

Conveyor pulleys are integral components in various industries ranging from mining and manufacturing to food processing and logistics. Their primary function involves facilitating the movement and support of the conveyor belt, which is critical for efficient material handling. A thorough understanding of the different types of conveyor pulleys and their specific applications is crucial for optimizing conveyor systems for improved performance and longevity.

Wing pulleys, distinctively designed with pointed wings, are utilized in applications that handle wet or damp materials. The unique design prevents material buildup on the pulley surface by expelling debris to the sides. This is especially important in industries where material accumulation might lead to belt damage or misalignment. Thus, wing pulleys extend the operational life of conveyor systems in challenging environments. Specialty pulleys are customized types designed for specific industry needs. Spiral pulleys, for example, feature a continuous helical design that aids in cleaning the belt surface and preventing material accumulation, which can be beneficial in industries dealing with fine powders or viscous substances. Similarly, ceramic lagging on pulleys provides additional grip and wear resistance, suitable for abrasive environments. Selecting the right type of conveyor pulley not only ensures efficient operation but also minimizes maintenance costs. It requires an understanding of the specific needs of the application, including belt tension requirements, expected loads, environmental factors, and the nature of the materials being transported. Consulting with manufacturers and suppliers who possess deep industry expertise can provide valuable insights into making the optimal choice. In doing so, businesses can significantly enhance operational productivity, safety, and cost-efficiency. The longevity and performance of a conveyor system hinge on the strategic selection and maintenance of conveyor pulleys. Regular inspections and timely replacements or upgrades can prevent unexpected failures, thus safeguarding both productivity and worker safety. Prioritizing these considerations solidifies an organization's competitive edge in a demanding market landscape.

Wing pulleys, distinctively designed with pointed wings, are utilized in applications that handle wet or damp materials. The unique design prevents material buildup on the pulley surface by expelling debris to the sides. This is especially important in industries where material accumulation might lead to belt damage or misalignment. Thus, wing pulleys extend the operational life of conveyor systems in challenging environments. Specialty pulleys are customized types designed for specific industry needs. Spiral pulleys, for example, feature a continuous helical design that aids in cleaning the belt surface and preventing material accumulation, which can be beneficial in industries dealing with fine powders or viscous substances. Similarly, ceramic lagging on pulleys provides additional grip and wear resistance, suitable for abrasive environments. Selecting the right type of conveyor pulley not only ensures efficient operation but also minimizes maintenance costs. It requires an understanding of the specific needs of the application, including belt tension requirements, expected loads, environmental factors, and the nature of the materials being transported. Consulting with manufacturers and suppliers who possess deep industry expertise can provide valuable insights into making the optimal choice. In doing so, businesses can significantly enhance operational productivity, safety, and cost-efficiency. The longevity and performance of a conveyor system hinge on the strategic selection and maintenance of conveyor pulleys. Regular inspections and timely replacements or upgrades can prevent unexpected failures, thus safeguarding both productivity and worker safety. Prioritizing these considerations solidifies an organization's competitive edge in a demanding market landscape.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS