Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor pulley suppliers

Understanding Conveyor Pulley Suppliers A Key to Efficient Material Handling

In the ever-evolving landscape of manufacturing and material handling, the importance of conveyor systems cannot be overstated. Central to these systems are conveyor pulleys, which play a crucial role in enabling the efficient movement of goods and materials. As industries look to optimize their operations, finding reliable conveyor pulley suppliers has become increasingly important.

What are Conveyor Pulleys?

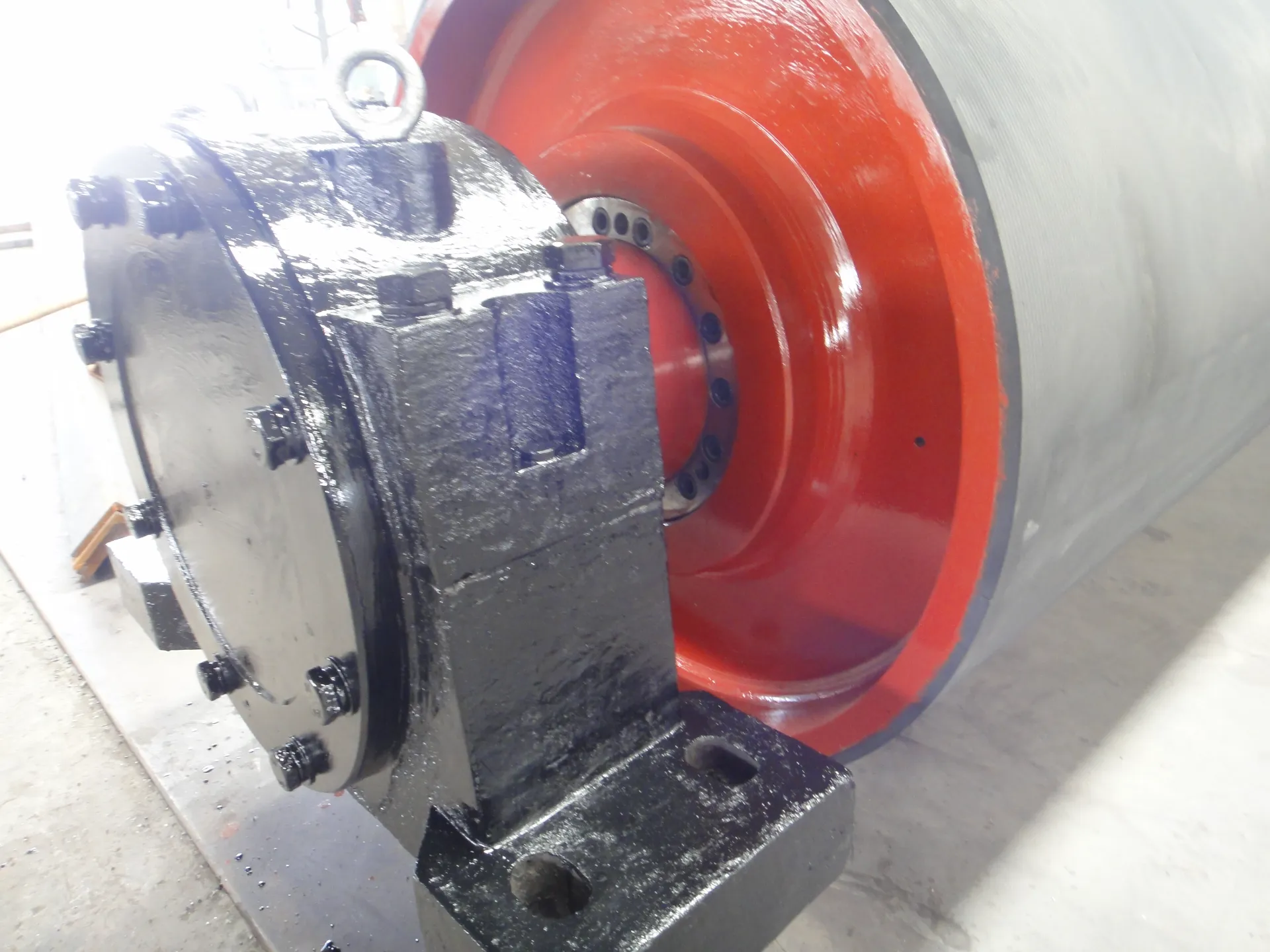

Conveyor pulleys are vital components of any conveyor system. They are cylindrical devices used to enhance the functionality of the conveyor belt by exerting tension and redirecting the belt. Generally, pulleys can be classified into three major types drive pulleys, tail pulleys, and snub pulleys. Drive pulleys are responsible for powering the system, tail pulleys provide tension, and snub pulleys help with belt alignment and support.

The Role of Suppliers in Conveyor Systems

Conveyor pulley suppliers provide the essential components needed for effective material handling systems. Their role goes beyond merely supplying products; they also contribute to system design, integration, maintenance, and support. Choosing the right supplier can therefore lead to better system performance, longevity, and overall efficiency.

When evaluating a conveyor pulley supplier, several factors should be considered

1. Quality of Materials The durability and performance of conveyor pulleys heavily depend on the materials used in their construction. Reliable suppliers use high-quality steel, rubber, and other materials that ensure long-lasting performance even under harsh conditions.

2. Customization Options Every industry has unique requirements. A good supplier offers customizable solutions tailored to specific needs, including size, load capacity, and environmental considerations.

3. Industry Experience Suppliers that have a wealth of experience in the industry are typically more reliable. They understand the complexities involved in material handling and can offer valuable insights into which products will best suit particular applications.

conveyor pulley suppliers

5. Cost-Effectiveness While quality is paramount, cost considerations also play a significant role. Finding a supplier that offers a balance of affordability and quality can help companies maintain their bottom line while ensuring operational efficiency.

Key Benefits of Choosing the Right Supplier

Working with a reputable conveyor pulley supplier can yield numerous benefits

- Enhanced Performance Quality pulleys contribute significantly to the smooth operation of conveyor systems, reducing downtime and enhancing productivity. - Reduced Maintenance Costs High-quality pulleys have fewer breakdowns, leading to lower repair and replacement costs. This not only saves money but also reduces production interruptions.

- Improved Safety Reliable suppliers prioritize safety standards in their products. Using pulleys that meet industry regulations ensures a safer work environment for employees.

- Long-Term Partnerships Establishing a relationship with a trusted supplier fosters collaboration. This partnership can lead to future innovations, advancements, and tailored solutions as your business evolves.

Conclusion

In conclusion, conveyor pulley suppliers play a vital role in the efficiency of material handling systems across various industries. Understanding the significance of quality, customization, experience, technical support, and cost-effectiveness can help businesses make informed decisions when selecting a supplier. The right conveyor pulley supplier not only provides high-quality products but also works as a partner in improving operational efficiency and ensuring the long-term success of material handling processes.

As industries continue to grow and evolve, the quest for reliable conveyor pulley suppliers remains a critical factor in achieving optimal performance. By investing in quality components from reputable suppliers, businesses can enhance their systems, reduce costs, and achieve higher levels of operational effectiveness. Therefore, it is essential for companies to conduct thorough research, evaluate their options, and select suppliers that align with their specific material handling needs.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025