Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor pulley manufacturers

Conveyor Pulley Manufacturers Essential Players in Material Handling

In the industrial world, efficiency and reliability are of paramount importance, especially when it comes to transportation systems used in manufacturing, mining, and logistics. One of the critical components in these systems is the conveyor pulley. Conveyor pulleys play a vital role in the functioning of conveyor belts, and as industries grow, so does the demand for high-quality conveyor pulley manufacturers. This article will explore the significance of conveyor pulleys, the qualities to look for in a manufacturer, and the present landscape of the market.

Understanding Conveyor Pulleys

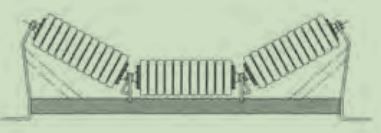

Conveyor pulleys are cylindrical devices that are used to support the conveyor belt and help in the movement of materials. They are a fundamental part of any conveyor system, as they provide the necessary tension, redirect the belt to move materials more efficiently, and assist in the loading and unloading processes. Typically, conveyor pulleys come in several types, including drive pulleys, tail pulleys, bend pulleys, and snub pulleys, each serving different functions depending on the system's requirements.

The proper functioning of a conveyor system depends heavily on the quality and performance of its pulleys. A well-designed pulley can significantly enhance the durability of the entire conveyor system, reduce maintenance costs, and ensure smooth operation. Therefore, choosing the right conveyor pulley manufacturer becomes a crucial decision for businesses seeking to optimize their material handling processes.

What to Look for in Conveyor Pulley Manufacturers

When searching for a reputable conveyor pulley manufacturer, several factors should be taken into consideration

1. Technology and Innovation Look for manufacturers that employ the latest manufacturing technologies and innovative designs. Advanced engineering processes can lead to more durable, efficient, and flexible pulley systems that meet specific operational needs.

2. Quality Assurance A good manufacturer should adhere to stringent quality control measures. Check for certifications like ISO, which indicate that the manufacturer meets international standards for quality and safety.

3. Custom Solutions Different industries have varying requirements. A manufacturer that offers custom pulleys designed to meet specific operational challenges will be more valuable than one that provides only standard models.

conveyor pulley manufacturers

4. Materials Used The material used to construct pulleys impacts their strength, weight, and durability. Top manufacturers use high-grade materials such as steel, aluminum, and specially formulated composites, ensuring long-lasting performance.

5. Customer Support and Service Reliable customer support is essential for dealing with any issues that may arise post-purchase. This includes providing assistance with installation, maintenance, and repairs.

6. Industry Experience Experience in the field can often translate to better products. Manufacturers with a long-standing reputation typically have honed their skills and knowledge over years of operation.

The Conveyor Pulley Market Today

The conveyor pulley manufacturing industry has seen considerable growth due to increased industrialization and the expansion of sectors requiring material handling solutions, such as mining, construction, and retail. The global market tends to favor manufacturers that offer eco-friendly solutions, as there is a rising demand for sustainability in industrial operations.

As of now, many manufacturers are focusing on enhancing their product offerings by integrating smart technologies. This includes the incorporation of sensors and IoT technologies that allow for real-time monitoring and predictive maintenance of conveyor systems, thereby minimizing downtime and improving productivity.

Moreover, globalization has made it easier for companies to source conveyor pulleys from manufacturers around the world. However, this also means businesses need to be mindful of sourcing practices and ensure that they are partnering with manufacturers prioritizing ethical labor practices and environmental responsibility.

Conclusion

Conveyor pulleys are indispensable in the smooth operation of conveyor systems across various industries. As such, choosing the right manufacturer is crucial for businesses aiming to enhance efficiency, reliability, and ultimately, profitability. By focusing on quality, innovation, and customer service, a well-chosen conveyor pulley manufacturer can become a vital partner in navigating the complexities of material handling. As industries continue to evolve, the demand for customizable and technologically advanced conveyor pulleys will only increase, further highlighting the importance of selecting a manufacturer that aligns with your operational needs and values.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025