Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor pulley manufacturers

Conveyor Pulley Manufacturers An Essential Component of Material Handling Systems

In the world of material handling, the importance of conveyor systems cannot be overstated. At the heart of these systems lies a crucial component conveyor pulleys. Conveyor pulleys play a vital role in ensuring the smooth and efficient operation of conveyor belts, making the manufacturers of these components an essential part of industrial processes across various sectors.

Understanding Conveyor Pulleys

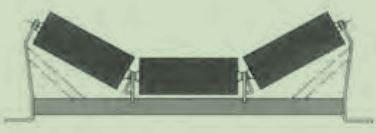

Conveyor pulleys are mechanical devices used to support and drive conveyor belts. They come in various types, including drive pulleys, return pulleys, and snub pulleys, each serving a specific function. Drive pulleys are responsible for powering the conveyor, while return pulleys help maintain the tension and alignment of the belt. Snub pulleys, on the other hand, aid in increasing the wrap angle of the belt around the drive pulley, enhancing the grip and efficiency of the system.

The construction of conveyor pulleys typically involves robust materials such as steel or aluminum, ensuring durability and longevity even in harsh industrial environments. The design of these pulleys also includes features that accommodate various belt sizes, loads, and application conditions, thus catering to a wide array of industries, including mining, manufacturing, and logistics.

The Role of Manufacturers

Conveyor pulley manufacturers are tasked with producing high-quality pulleys that meet the diverse needs of their clients

. In this competitive market, manufacturers must invest in advanced technologies and stringent quality control measures to ensure their products not only meet but exceed industry standards.conveyor pulley manufacturers

A significant aspect of manufacturing conveyor pulleys involves selecting the right materials and employing precise engineering practices. Manufacturers often work closely with engineers and designers to develop custom solutions tailored to specific customer requirements. This collaborative process is crucial, as it ensures that the pulleys can withstand the unique challenges posed by different applications, such as heavy loads, extreme temperatures, and abrasive materials.

Innovations in Conveyor Pulley Manufacturing

In the ever-evolving industrial landscape, conveyor pulley manufacturers are embracing innovative technologies to improve their products. Automation in manufacturing processes is becoming increasingly prevalent, allowing for greater precision, efficiency, and consistency in pulley production. Additionally, advancements in materials science have led to the development of lighter yet stronger materials that can enhance performance while reducing wear and tear on belts and other system components.

Another area of focus is sustainability. Many manufacturers are now prioritizing eco-friendly practices, incorporating recyclable materials into their products, and optimizing production processes to reduce waste and energy consumption. This shift not only benefits the environment but also meets the growing demand from consumers for sustainable practices in industrial operations.

Conclusion

Conveyor pulley manufacturers are integral to the functionality and efficiency of material handling systems across various industries. By focusing on quality, innovation, and sustainability, these manufacturers play a pivotal role in enhancing the performance of conveyor systems, which in turn supports the smooth operation of countless businesses worldwide. As technology continues to advance, the future of conveyor pulley manufacturing looks promising, with more opportunities for customization, efficiency, and environmental responsibility. Therefore, choosing the right conveyor pulley manufacturer is crucial for businesses looking to optimize their operations and achieve long-term success in their respective markets.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025