Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor pulley components

Understanding Conveyor Pulley Components A Comprehensive Overview

Conveyor systems are integral to various industries, facilitating the transportation of materials efficiently and with minimal effort. At the heart of these systems lies the conveyor pulley, a critical component that plays a significant role in movement and stability. Understanding the components of a conveyor pulley can enhance efficiency, reduce maintenance costs, and improve overall system functionality.

What is a Conveyor Pulley?

A conveyor pulley is a cylindrical device used in conveyor systems to support and guide the belt. It helps in changing the direction of the belt and is crucial in ensuring that the materials being transported remain stable and properly aligned. Conveyor pulleys can be classified into different categories based on their function, namely drive pulleys, return pulleys, bend pulleys, and snub pulleys.

Key Components of Conveyor Pulleys

1. Drum Shell The drum shell is the cylindrical body of the pulley, typically made from robust materials such as steel or aluminum. Its design directly affects the pulley’s performance, as it must withstand the wear and tear from the bulk materials being transported.

2. End Disc The end discs are the circular plates fixed to either end of the drum shell. They provide structural integrity to the pulley system, ensuring that the conveyor belt remains properly aligned during operation. The end discs must be constructed to match the durability of the drum shell, often utilizing welded seams to withstand heavy loads.

3. Shaft The shaft is a vital component that transmits power from the motor to the pulley. It serves as the core around which the drum shell rotates. Proper selection and installation of the shaft are essential as it must handle high torsional loads and rotational stresses without failure.

conveyor pulley components

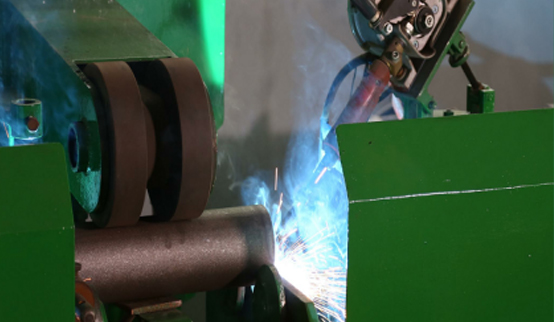

4. Lagging Lagging is a surface material applied to the drum shell to improve friction between the pulley and the conveyor belt. It enhances traction and reduces slippage, ensuring that the belt maintains a steady movement even under heavy loads. Various lagging materials, such as rubber or ceramic, can be used depending on the specific application and environmental conditions.

5. Bearings Bearings facilitate smooth rotation of the pulley by reducing friction between the moving parts. They are critical for the longevity of the conveyor system, as worn-out bearings can lead to increased resistance and premature failure. The choice of bearings depends on the load requirements and environmental factors like temperature and moisture.

6. Seal Seals are used to protect the bearings from dust, dirt, and water ingress, extending their lifespan and reducing maintenance needs. Proper sealing is crucial in preventing lubrication loss and ensuring optimal performance, especially in harsh operating conditions.

Importance of High-Quality Conveyor Pulley Components

The effectiveness and longevity of conveyor systems rely heavily on the quality of their components. High-quality pulleys reduce the likelihood of system failures, ensuring smooth and uninterrupted operation. Regular inspections and maintenance can identify wear and tear early, allowing for timely replacements of pulleys or their components, thus minimizing downtime.

Moreover, purchasing conveyor pulleys from reputable manufacturers ensures that industry standards are met. Quality components can significantly enhance the safety and efficiency of operations, contributing to the overall productivity of a facility.

Conclusion

In summary, conveyor pulleys are essential components that influence the performance and efficiency of conveyor systems. By understanding the various components, such as the drum shell, end discs, shafts, lagging, bearings, and seals, operators can make informed decisions regarding maintenance and upgrades. Investing in high-quality conveyor pulley components not only boosts operational efficiency but also enhances the reliability and safety of material handling processes. As industries continue to evolve, so too should our approach to managing these integral systems, focusing on quality and performance to meet modern demands.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025