Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor pulley catalogue

Understanding Conveyor Pulley Catalogues Key Features and Considerations

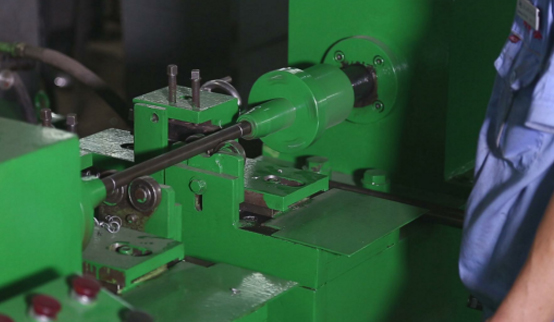

Conveyor pulleys are vital components in material handling systems, enabling the efficient transportation of various materials within industries such as mining, manufacturing, and logistics. A conveyor pulley catalogue serves as a comprehensive guide for engineers, procurement specialists, and maintenance personnel to select the right pulleys for their specific applications. This article outlines the critical features and considerations when examining a conveyor pulley catalogue.

Types of Conveyor Pulleys

A well-structured conveyor pulley catalogue typically categorizes pulleys into different types based on their functionality and design. The primary types include

1. Drive Pulleys These are essential for the propulsion of the conveyor belt. They are usually situated at the head of the conveyor and are powered by a motor, converting electrical energy into mechanical motion.

2. Idler Pulleys Positioned along the conveyor system, these pulleys help support and guide the belt. They play a crucial role in maintaining tension and alignment, ensuring smooth operation.

3. Return Pulleys Located at the tail end of the conveyor, return pulleys facilitate the return journey of the conveyor belt. They help prevent excessive sagging and ensure the belt maintains its trajectory.

4. Specialty Pulleys These include wing pulleys and crowned pulleys, designed for specific operational challenges, such as improving material discharge or enhancing belt traction.

Material and Construction

The catalogue will provide insights into the materials used for constructing the pulleys, which is critical for determining their durability and performance. Common materials include

conveyor pulley catalogue

- Steel Known for its strength, steel is often used for heavy-duty applications. - Aluminum Lightweight and resistant to corrosion, aluminum pulleys are beneficial for environments where weight savings are essential. - Composite Materials Increasingly popular for specific applications, composite pulleys offer a balance of strength and weight, along with resistance to chemicals and environmental factors.

Sizing and Specifications

Another crucial aspect of a conveyor pulley catalogue is the sizing and specifications of the pulleys. Proper sizing is essential for ensuring that the pulleys fit seamlessly within the conveyor system and operate efficiently. The catalogue should provide detailed measurements, including

- Diameter - Face width - Shaft size - Weight capacity

It may also include specific information on the pulley’s load ratings and allowable belt tensions, helping users match the right pulley to their system requirements.

Maintenance and Safety

An excellent conveyor pulley catalogue will also incorporate information on maintenance requirements and safety features. Proper maintenance schedules can prolong the life of pulleys, whereas built-in safety features can prevent belt slippage and reduce operational risks.

Conclusion

In conclusion, a conveyor pulley catalogue is a comprehensive resource that helps users make informed decisions regarding the selection and application of conveyor pulleys. By understanding the various types, materials, specifications, and maintenance practices outlined in the catalogue, professionals can optimize their conveyor systems for improved efficiency and reliability. Whether in mining, manufacturing, or logistics, the right conveyor pulleys are fundamental to ensuring smooth operations and material handling processes.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025