Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 15, 2025 04:26

Back to list

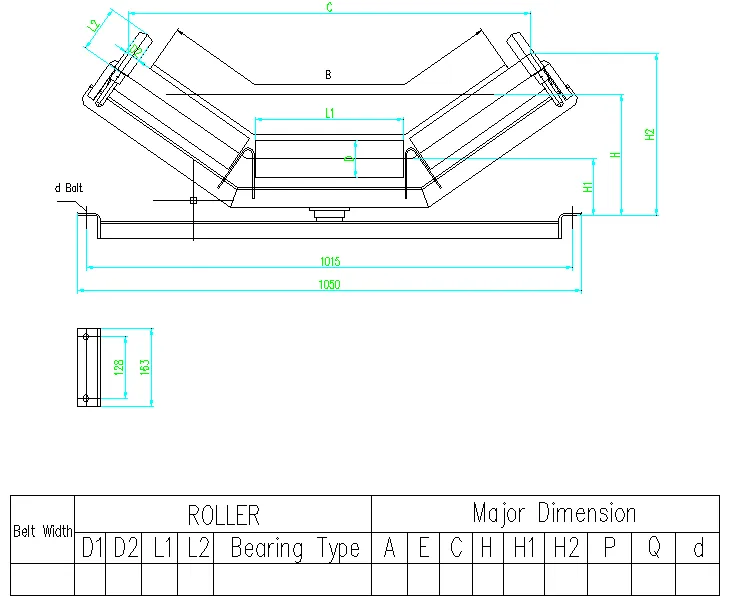

conveyor roller parts

In the competitive landscape of the manufacturing and logistics industries, finding reliable conveyor parts suppliers can greatly influence the efficiency and productivity of operations. Conveyor systems form the backbone of material handling and are integral to diverse sectors such as automotive, food processing, packaging, and e-commerce. Selecting the right supplier not only ensures smooth operations but also enhances business outcomes.

Additionally, economic factors should not be ignored. A cost-effective supplier offers a balance between affordability and quality. Long-term partnerships with such suppliers can lead to cost savings not only through competitive pricing but also through value-added services such as regular maintenance, ensuring reduced downtime and extending the lifespan of the conveyor systems. One of the most critical directions in selecting conveyor parts suppliers is to consider their innovation capacity. Suppliers who invest in research and development can provide cutting-edge solutions that improve efficiency and reduce operational costs. They explore alternative materials, automate processes, and ensure energy-efficient system designs. Partnering with such forward-thinking suppliers positions businesses to gain a competitive advantage by embracing innovation in their operations. Moreover, it's crucial for suppliers to be flexible and scalable, capable of meeting the evolving needs of businesses as they grow. They should offer a comprehensive range of products and have the ability to customize parts to fit unique conveyor system designs. Their capacity for scalability indicates readiness to support increased demands and adapt to new challenges as they arise. Finally, sustainability is a growing concern in today’s global market. Suppliers committed to sustainable practices help clients align with eco-friendly initiatives. They offer products designed with sustainability in mind, using recyclable materials and manufacturing processes that minimize environmental impact. In conclusion, choosing a conveyor parts supplier is a decision that requires a strategic evaluation of their experience, expertise, authoritativeness, and trustworthiness. A supplier that excels in these areas can significantly enhance a company’s operational capabilities, ensuring efficient material handling and supporting sustainable business growth. By focusing on these crucial factors, businesses can forge strong partnerships with suppliers that are not only aligned with their current needs but are also equipped to support their future ambitions.

Additionally, economic factors should not be ignored. A cost-effective supplier offers a balance between affordability and quality. Long-term partnerships with such suppliers can lead to cost savings not only through competitive pricing but also through value-added services such as regular maintenance, ensuring reduced downtime and extending the lifespan of the conveyor systems. One of the most critical directions in selecting conveyor parts suppliers is to consider their innovation capacity. Suppliers who invest in research and development can provide cutting-edge solutions that improve efficiency and reduce operational costs. They explore alternative materials, automate processes, and ensure energy-efficient system designs. Partnering with such forward-thinking suppliers positions businesses to gain a competitive advantage by embracing innovation in their operations. Moreover, it's crucial for suppliers to be flexible and scalable, capable of meeting the evolving needs of businesses as they grow. They should offer a comprehensive range of products and have the ability to customize parts to fit unique conveyor system designs. Their capacity for scalability indicates readiness to support increased demands and adapt to new challenges as they arise. Finally, sustainability is a growing concern in today’s global market. Suppliers committed to sustainable practices help clients align with eco-friendly initiatives. They offer products designed with sustainability in mind, using recyclable materials and manufacturing processes that minimize environmental impact. In conclusion, choosing a conveyor parts supplier is a decision that requires a strategic evaluation of their experience, expertise, authoritativeness, and trustworthiness. A supplier that excels in these areas can significantly enhance a company’s operational capabilities, ensuring efficient material handling and supporting sustainable business growth. By focusing on these crucial factors, businesses can forge strong partnerships with suppliers that are not only aligned with their current needs but are also equipped to support their future ambitions.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS