Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 15, 2025 03:42

Back to list

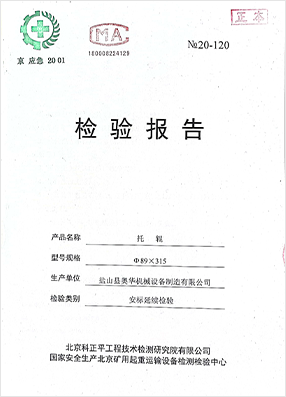

conveyor roller parts

In the world of material handling industries, conveyor parts play a crucial role in ensuring the seamless flow of operations. Understanding the intricacies of these components can dramatically enhance efficiency and productivity in various sectors, from manufacturing to shipping logistics.

Trustworthiness in choosing and recommending conveyor parts can only be cultivated through a track record of success and transparency. Companies need to document and share case studies showcasing successful implementations and sustained improvements resulting from high-quality conveyor components. An honest assessment of the costs versus the benefits of specific parts, supported by evidence from previous projects, builds client confidence. Engaging with clients through educational content, such as workshops or detailed blog posts, also fosters trust and emphasizes a commitment to client success. A meticulous approach to conveyor part selection involves a thorough analysis of cost-effectiveness without compromising on quality. It's essential to consider not only the upfront cost but also the part's longevity, maintenance requirements, and overall contribution to system efficiency. Custom solutions often provide substantial long-term benefits by reducing operational disruptions and energy consumption, further solidifying a company's reputation for delivering reliable and sustainable conveyor solutions. Additionally, fostering strong relationships with suppliers ensures a steady supply of high-quality parts. Leveraging these relationships can result in better pricing and quicker response times for procuring parts, which is critical when a system component unexpectedly fails. Building a robust supply chain is an often-overlooked aspect that significantly contributes to both the competitiveness and credibility of a conveyor solutions provider. In conclusion, the domain of conveyor parts is complex yet fascinating, requiring a balanced blend of experience, expertise, authoritativeness, and trustworthiness to navigate successfully. By embracing technological advances and fostering transparent client relationships, companies can optimize their conveyor systems to achieve superior performance and reliability. Whether upgrading an existing system or building a new one, careful consideration of all aspects, including component quality, system requirements, and long-term sustainability, ensures a conveyor system that meets and exceeds industry demands.

Trustworthiness in choosing and recommending conveyor parts can only be cultivated through a track record of success and transparency. Companies need to document and share case studies showcasing successful implementations and sustained improvements resulting from high-quality conveyor components. An honest assessment of the costs versus the benefits of specific parts, supported by evidence from previous projects, builds client confidence. Engaging with clients through educational content, such as workshops or detailed blog posts, also fosters trust and emphasizes a commitment to client success. A meticulous approach to conveyor part selection involves a thorough analysis of cost-effectiveness without compromising on quality. It's essential to consider not only the upfront cost but also the part's longevity, maintenance requirements, and overall contribution to system efficiency. Custom solutions often provide substantial long-term benefits by reducing operational disruptions and energy consumption, further solidifying a company's reputation for delivering reliable and sustainable conveyor solutions. Additionally, fostering strong relationships with suppliers ensures a steady supply of high-quality parts. Leveraging these relationships can result in better pricing and quicker response times for procuring parts, which is critical when a system component unexpectedly fails. Building a robust supply chain is an often-overlooked aspect that significantly contributes to both the competitiveness and credibility of a conveyor solutions provider. In conclusion, the domain of conveyor parts is complex yet fascinating, requiring a balanced blend of experience, expertise, authoritativeness, and trustworthiness to navigate successfully. By embracing technological advances and fostering transparent client relationships, companies can optimize their conveyor systems to achieve superior performance and reliability. Whether upgrading an existing system or building a new one, careful consideration of all aspects, including component quality, system requirements, and long-term sustainability, ensures a conveyor system that meets and exceeds industry demands.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS