Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Conveyor Support Brackets for Secure Mounting and Optimal Performance

Understanding Conveyor Mounting Brackets Essential Components for Efficient Operations

Conveyor systems are vital in various industries, playing a crucial role in material handling and transportation. One of the key components that ensure the effective operation of these systems is the conveyor mounting brackets. These specialized brackets serve as the foundation for supporting conveyor belts, rollers, and other elements, ensuring stability and precision throughout the handling process.

What Are Conveyor Mounting Brackets?

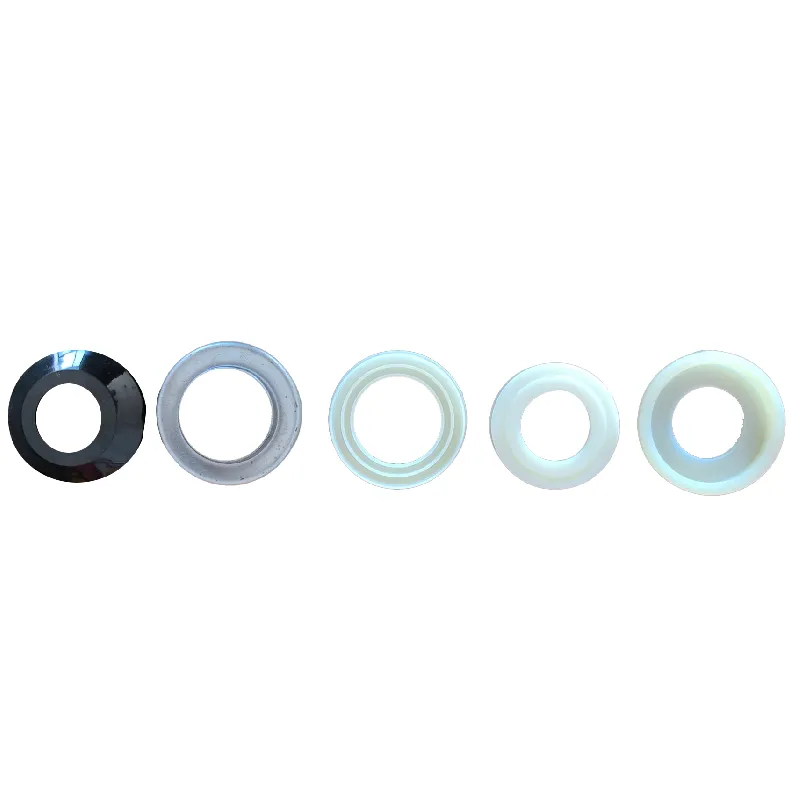

Conveyor mounting brackets are hardware accessories that allow for the secure attachment of conveyor components to a frame or structural element. They come in different designs and materials, tailored to support specific types of conveyors depending on their size, weight, and operational requirements. Common materials used for these brackets include steel, aluminum, and plastic, each offering unique benefits in terms of durability, weight, and corrosion resistance.

Importance of Proper Mounting Bracket Installation

The installation of mounting brackets is a critical step in setting up a conveyor system. Properly installed brackets ensure the alignment of the conveyor components, which is vital for smooth operation and longevity. Misalignment can lead to increased wear and tear on parts, resulting in frequent maintenance, downtime, and associated costs. Therefore, investing time and resources in the correct installation of mounting brackets pays off in the long run.

Types of Conveyor Mounting Brackets

There are several types of conveyor mounting brackets, each designed for specific applications

. The most common types includeconveyor mounting brackets

1. Fixed Brackets These are stationary and provide a stable anchor point for various conveyor components. They are typically used in applications where the conveyor does not need to be moved frequently.

2. Adjustable Brackets These brackets allow for height and angle adjustments, which is beneficial for conveyors that need to adapt to different operational scenarios.

3. Hanging Brackets Used in overhead conveyor systems, these brackets help suspend the conveyor from above, saving floor space and allowing for flexible layout configurations.

4. Low-profile Brackets Designed for compact applications, low-profile brackets provide a sleek design while ensuring strong support for the conveyor components.

Selecting the Right Bracket

When choosing conveyor mounting brackets, several factors need to be considered. These include the weight of the materials being transported, the environmental conditions (e.g., exposure to moisture or chemicals), and the specific layout of the conveyor system. Consulting with professionals who understand the nuances of material handling equipment can help select the best brackets for your needs.

In conclusion, conveyor mounting brackets are essential components that contribute significantly to the overall efficiency and reliability of conveyor systems. Understanding their types, functions, and proper installation techniques can enhance operational effectiveness, reduce maintenance costs, and ultimately lead to smoother production processes. Investing in high-quality mounting brackets is a smart move for any business relying on conveyor systems for material handling.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025