Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor machine parts

Understanding Conveyor Machine Parts A Comprehensive Overview

Conveyor machines are essential components in various industries, serving as crucial systems to transport materials efficiently. They are used in manufacturing, packaging, warehousing, and distribution, making them pivotal in enhancing productivity and reducing manual labor. However, like any machinery, conveyor systems rely on numerous specific parts, each playing a vital role in the conveyor's overall functionality. In this article, we will explore the essential parts of conveyor machines and their significance.

1. Frame

The frame of a conveyor machine provides the structural foundation upon which all other components are mounted. Typically made from sturdy materials such as steel or aluminum, the frame’s design ensures stability and durability under heavy loads. The frame’s shape and design can vary significantly depending on the application, be it a belt conveyor, roller conveyor, or chain conveyor system.

2. Conveyor Belt

Perhaps the most recognizable part of a conveyor system is the conveyor belt itself. This continuous loop of material transports items along the conveyor’s length. Conveyor belts can be made from various materials, including rubber, metal, fabric, or plastic, depending on the type of goods being conveyed and the environmental conditions. Belts can also have different surface textures to provide appropriate grip and support for the items being moved.

3. Drive System

The drive system is responsible for powering the conveyor. Typically consisting of a motor, gears, and rollers, the drive system converts electrical energy into mechanical energy. The choice of motor size and type will depend on the specific application and load requirements. A properly sized drive system ensures smooth operation, preventing slippage or jamming, which could disrupt productivity.

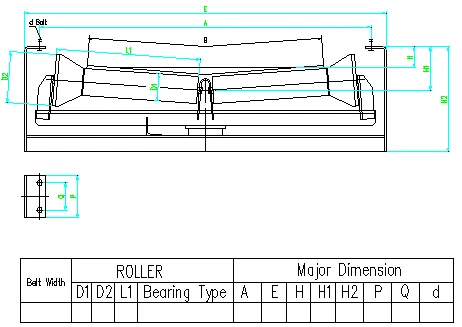

Rollers are critical components that support the conveyor belt and assist in transportation. They can be found under the belt in a series, allowing for smooth movement as the belt glides over them. Additionally, tensioners are used to maintain proper tension in the conveyor belt, preventing it from becoming too loose or too tight, which could lead to operational issues or premature wear.

conveyor machine parts

5. Idlers

Idlers are similar to rollers but primarily serve to support the load and keep the belt aligned. Positioned along the conveyor’s return path, they help maintain the belt’s shape and prevent sagging. Idlers are crucial in ensuring that the conveyor system operates efficiently and, like rollers, can affect the durability and longevity of the conveyor belt.

6. Pulleys and Sheaves

Pulleys are crucial for guiding the conveyor belt and are often found at the ends of the conveyor system. They help to redirect the belt at its terminus and can also assist with tension adjustments. Sheaves work in conjunction with pulleys to facilitate the smooth operation of the belt, particularly in powered conveyors. The choice of materials and the design of pulleys are important for minimizing wear and tear on the conveyor belt.

7. Controls and Sensors

Modern conveyor systems often come equipped with control systems and sensors that enhance functionality. Controls may include variable frequency drives (VFDs) or programmable logic controllers (PLCs) that allow for automation and integration with other machinery. Sensors are integral for monitoring the system performance, detecting malfunctions, and ensuring safety by stopping the conveyor in emergencies.

8. Safety Devices

Safety is paramount in any operational setting involving heavy machinery. Conveyor systems are equipped with various safety devices, including emergency stop buttons, safety guards, and warning lights. These features help protect workers and equipment, minimizing the risk of accidents and ensuring compliance with safety regulations.

Conclusion

Understanding the various parts of conveyor machines is essential for anyone involved in manufacturing, logistics, or any industry that relies on these systems for efficient material handling. Each component, from the frame to the safety devices, plays an integral role in the conveyor's performance and longevity. With the right maintenance and knowledge, conveyor systems can significantly enhance operational efficiency and productivity in any setting.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025