Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor idler types

Different Types of Conveyor Idlers

Conveyor systems are pivotal in various industries for the efficient transportation of materials. One critical component of these systems is the conveyor idler, which plays a crucial role in supporting the conveyor belt and ensuring smooth material movement. Idlers are designed in various configurations to optimize performance and enhance efficiency in material handling. In this article, we will explore the different types of conveyor idlers, their applications, and their significance in the overall conveyor system.

1. Roller Idlers

Roller idlers are the most common type of idler used in conveyor systems. They consist of a series of rollers mounted on frames, allowing for the belt to slide over them with minimal friction. Roller idlers are classified into three main categories carrying idlers, return idlers, and transition idlers.

- Carrying Idlers These idlers support the weight of the material being transported on the conveyor belt. They are typically arranged at regular intervals along the conveyor to provide adequate support. - Return Idlers Located on the return section of the conveyor, these idlers help guide the belt back to the loading point. They help maintain the belt’s alignment and support its weight during the return journey.

- Transition Idlers These are installed at points where the belt changes direction or transitions between various conveyor components. Transition idlers are critical for preventing belt sag and facilitating smooth transitions.

2. Impact Idlers

Impact idlers are designed to absorb the shock of heavy loads dropping onto the conveyor belt. They are strategically placed at loading points to minimize damage to the conveyor system. The rollers of impact idlers are typically equipped with shock-absorbing features to enhance their ability to withstand high-impact forces. This type of idler is particularly important in mining and heavy-duty applications where the loads can be substantial.

3. Training Idlers

conveyor idler types

Training idlers, or guide idlers, are used to maintain proper belt alignment throughout the conveyor system. Misalignment of the conveyor belt can lead to increased wear and tear, causing operational issues. Training idlers are designed to correct and adjust the position of the belt automatically, ensuring it runs straight and reducing the risk of spillage or damage.

4. Flat Idlers

Flat idlers consist of a flat surface instead of rollers. They are typically used in applications that require a smooth surface for the belt to travel on, such as in certain food processing or packaging industries. Flat idlers help maintain the integrity of the product being transported by minimizing the risk of damage during conveyance.

5. Specialty Idlers

In addition to the standard types of idlers mentioned above, there are also specialty idlers designed for specific applications. These can include

- Chevron Idlers Designed for handling materials at steep angles, these idlers feature a raised surface to prevent material from slipping off the belt.

- Belt Support Idlers Used in high-temperature or corrosive environments, these idlers are made from materials that can withstand adverse conditions.

Conclusion

In conclusion, conveyor idlers are essential components in the efficient operation of conveyor systems. Each type of idler serves a specific purpose, optimized for various applications and environments. Understanding the different types of conveyor idlers and their functions can help in selecting the appropriate solution for your material handling needs, ultimately enhancing productivity and minimizing operational disruptions. Whether in mining, manufacturing, or logistics, the right idler choice can significantly impact the overall efficiency of conveyor operations.

-

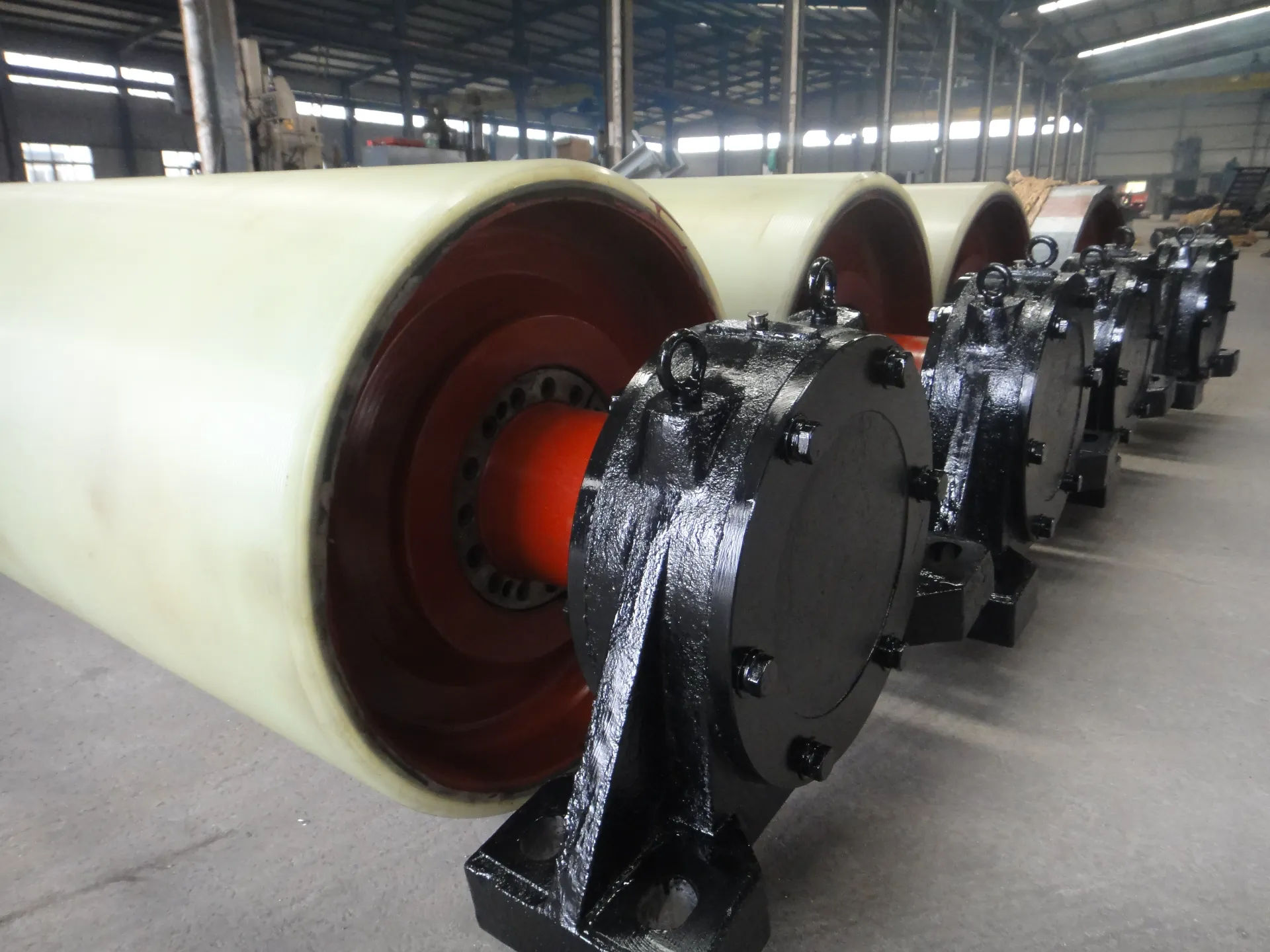

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025