Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor idler suppliers

Conveyor Idler Suppliers Key Players in Material Handling Solutions

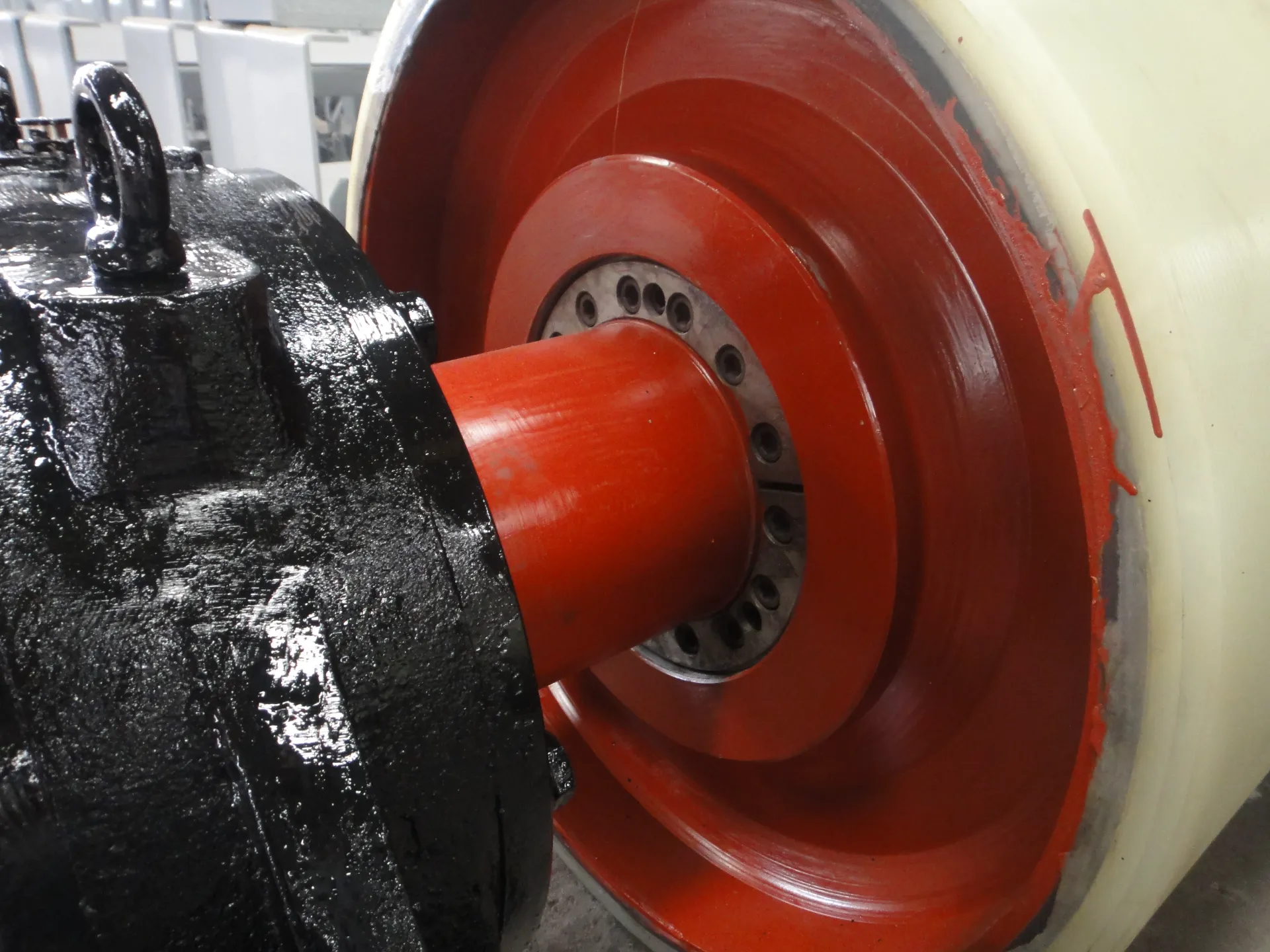

In the realm of material handling, conveyor systems play a pivotal role in enhancing productivity and efficiency. At the heart of these systems lies the conveyor idler, a crucial component that supports the belt and ensures smooth operation. As industries expand and the demand for efficient material movement grows, the role of conveyor idler suppliers becomes increasingly significant.

Conveyor idlers are designed to support the conveyor belt as it moves materials from one point to another. Their primary function is to reduce friction, maintain belt alignment, and extend the lifespan of the conveyor system. Given their importance, the choice of supplier for these components can greatly impact operational efficiency and maintenance costs.

The Importance of Choosing the Right Supplier

Selecting the right conveyor idler supplier involves more than just finding the lowest price. It requires a careful assessment of product quality, reliability, and service support. A good supplier will offer idlers made from durable materials that can withstand harsh operating conditions, reducing the likelihood of breakdowns and unscheduled maintenance. Moreover, suppliers with a solid reputation often provide detailed technical support, ensuring that clients receive products tailored to their specific needs.

Key Features to Look For in Conveyor Idler Suppliers

1. Product Range A reputable supplier should offer a diverse range of idlers, including troughing idlers, return idlers, impact idlers, and self-aligning idlers. This variety enables companies to select the idlers that best fit their unique conveyor systems.

conveyor idler suppliers

2. Quality Standards Suppliers that adhere to international quality standards ensure that their products are reliable and long-lasting. Certifications such as ISO 9001 can be a good indicator of a supplier's commitment to quality.

3. Customization Options Various industries have different requirements. A supplier that offers customization options can help businesses design idlers that meet specific operational needs, such as special coatings for corrosion resistance or adaptations for unique belt widths.

4. Technical Support Knowledgeable support staff can provide invaluable assistance in selecting the right products and designing systems. Excellent customer service helps foster long-term partnerships, where suppliers understand their clients' evolving needs and respond accordingly.

5. Innovative Solutions The industry is constantly evolving, with new technologies and materials on the horizon. Suppliers that invest in research and development can offer innovative conveyor idler solutions that enhance performance, reduce energy consumption, and improve overall system efficiency.

Conclusion

As the demand for efficient materials handling continues to rise, the importance of conveyor idler suppliers cannot be overstated. A well-chosen supplier not only provides high-quality products but also becomes a partner in enhancing operational efficiency and reducing costs. By prioritizing factors such as product range, quality, customization options, technical support, and innovation, companies can ensure they select a supplier that aligns with their operational goals. In the competitive landscape of material handling, leveraging the expertise of the right conveyor idler supplier can lead to significant advancements in efficiency and productivity, ultimately contributing to the overall success of the business.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025